Types of Hydraulic Cylinders

I. Introduction

Hydraulic Cylinders are essential components in various industrial applications, known for their ability to convert fluid power into linear mechanical force and motion. These cylinders come in multiple types, each designed to meet specific requirements and performance criteria. Understanding the different types of Hydraulic Cylinders can help in selecting the right one for any given application.

II. Types of Hydraulic Cylinders

Pull Hydraulic Cylinders

Pull hydraulic cylinders operate on the principle of Pascal's Law, which states that pressure applied to a confined fluid is transmitted undiminished in all directions. When hydraulic fluid is pumped into one side of the cylinder, it creates pressure that moves the piston. In a pull hydraulic cylinder, the hydraulic fluid is introduced on the side of the piston opposite to the rod side. This causes the piston to move towards the rod end, pulling the load attached to the rod.

Aluminum Hydraulic Cylinders

Aluminum hydraulic cylinders are known for their lightweight yet robust construction. They are ideal for applications where weight is a critical factor, such as in the aerospace and automotive industries. Despite their lighter weight, these cylinders offer excellent resistance to corrosion and high strength-to-weight ratios, making them suitable for demanding environments.

Locking Nut Hydraulic Cylinders

Locking nut hydraulic cylinders are designed with a mechanical locking mechanism that secures the load in place, even if there is a loss of hydraulic pressure. This feature makes them particularly useful for applications requiring prolonged holding of heavy loads, such as in construction and heavy machinery maintenance. The locking nut ensures safety and stability, preventing any accidental movements.

Single-Acting Hydraulic Cylinders

Single-acting hydraulic cylinders operate using hydraulic pressure applied in one direction only. A spring or external load usually achieves the return movement. These cylinders are simple, cost-effective, and widely used in applications where the force is required in only one direction, such as in lifting and clamping operations. requiring force

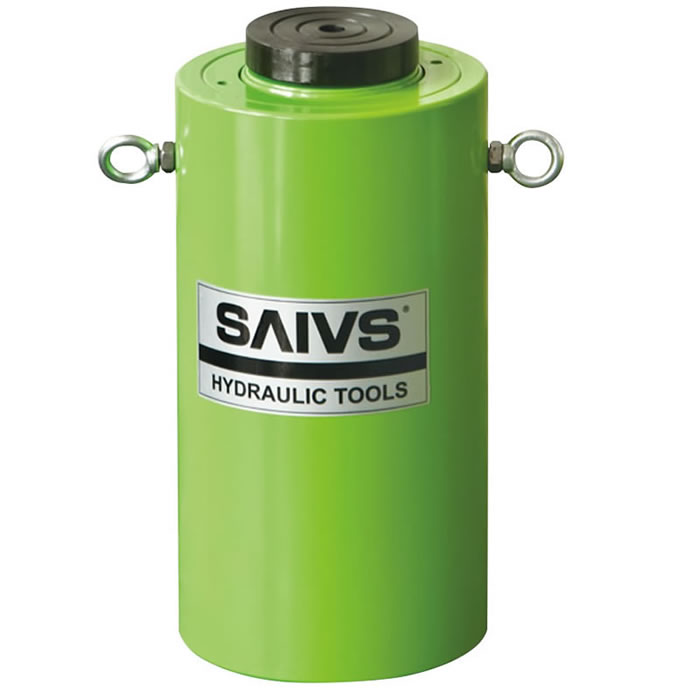

High Tonnage Hydraulic Cylinders

High-tonnage hydraulic cylinders are built to handle very heavy loads. These cylinders are constructed with high-strength materials to withstand substantial forces and are used in applications such as bridge lifting, shipbuilding, and heavy-duty construction. Their robust design ensures durability and reliable performance under extreme conditions.

III.Comparative Chart

Hydraulic cylinders are versatile and powerful actuators that are used in a wide variety of applications. By understanding the different types of hydraulic cylinders available, you can select the right cylinder for your specific application.

Here is a table that summarizes the key differences between the different types of hydraulic cylinders:

| Type | Key Features | Typical Applications |

|---|---|---|

| Aluminum Hydraulic Cylinders | Lightweight, corrosion-resistant | Aerospace, automotive, marine |

| Locking Nut Hydraulic Cylinders | Mechanical locking for load holding | Construction, heavy machinery maintenance |

| Single-Acting Hydraulic Cylinders | Simple, cost-effective, one-direction force | Lifting, clamping, positioning |

| Pull Hydraulic Cylinders | High Precision,Fits in tight spaces | Maintenance, repair, Material Handling |

| High Tonnage Hydraulic Cylinders | High strength, heavy load capacity | Bridge lifting, shipbuilding, heavy-duty construction |

Understanding the distinct characteristics and applications of each type of hydraulic cylinder can significantly aid in making informed decisions for specific industrial needs. Whether the requirement is for lightweight materials, compact designs, or handling high loads, there is a hydraulic cylinder designed to meet those needs efficiently.