what is the use of Rexroth hydraulic pumps on compactors?

What is the use of Rexroth Hydraulic pumps on compactors?

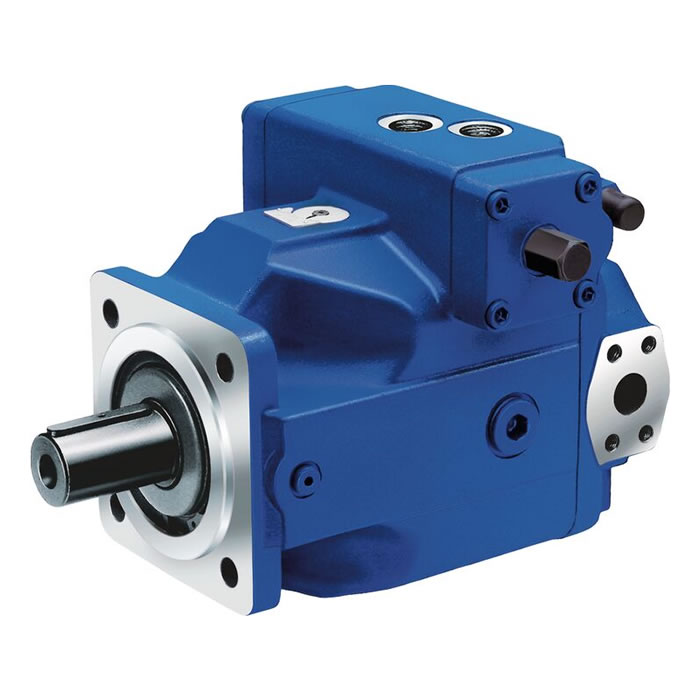

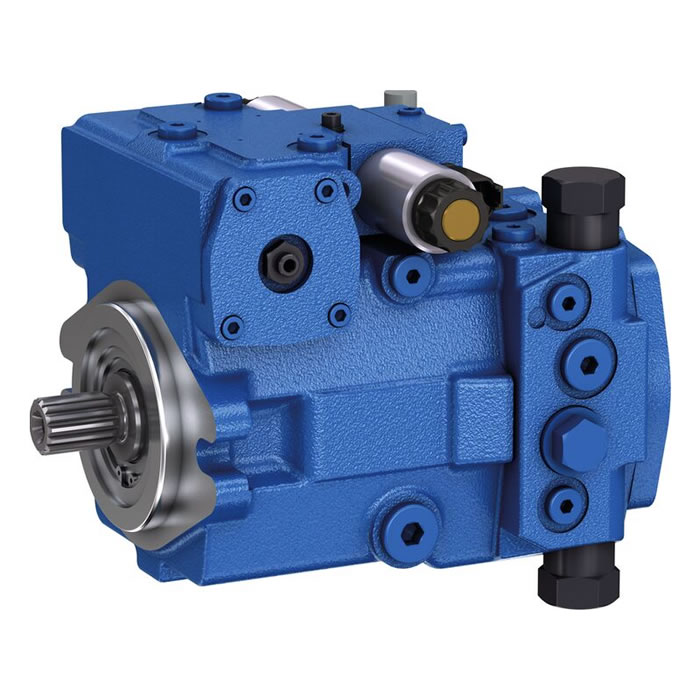

Regardless of the brand of hydraulic pump, such as Rexroth Hydraulic Pump, we know that Rexroth Hydraulic Pump is a hydraulic tank supplied by pneumatic pressure. After starting the machine each time, it must wait for the hydraulic stain box to reach the service pressure before operating the machine. Divided into two types: pressure-fed and self-priming. Pressure-supplied hydraulic pumps mostly use gas-filled tanks, but also have hydraulic pumps with oil-replenishing sub-pumps to supply pressure oil to hydraulic pump inlet. How about the use of Rexroth hydraulic pumps on compactors? Today, Koran Hydraulic will give you a detailed description of the use of Rexroth hydraulic pump on the roller as follows: Rexroth A10VNO Series piston pump I and self-priming hydraulic pump have strong self-priming ability and do not need external oil supply. For self-priming Vane Pumps, the oil in the hydraulic tank must not fall below the lower limit of the oil mark, and a sufficient amount of hydraulic oil must be maintained. The cleaner the hydraulic oil, the longer the service life of the hydraulic pump. In the 1970s, with the development of hydrostatic transmission technology, Weggs hydraulic control technology and computer technology, great progress has been made in the research of compaction technology and compaction equipment.

2. First, hydrostatic transmission is applied to compacting machinery. By controlling the flow rate of Hydraulic System, the speed of motor can be easily changed, and the continuous adjustment of vibrating frequency of roller can be realized, which greatly simplifies the complex transmission system. During this period, the research on vibratory compactor mainly focused on Optimization of parameters of vibratory compactor, and stepless and continuous adjustment of vibration frequency and amplitude was gradually realized, which improved compaction effect.

3. Pneumatic tyres are used for grinding wheels, generally 3-5 front wheels and 4-6 rear wheels. If the inflation pressure is changed, the ground pressure of tyre roller can be changed. The pressure range is 0.11~1.05 MPa. Tyre roller is driven by Weggs hydraulic, hydraulic or mechanical transmission system, single or full axle, and supported by wide-base articulated frame structure. Compaction process has rubbing effect, so that the compacted layer particles are not destroyed but embedded, uniform and dense. Good maneuverability and fast traveling speed (up to 25 km/h) for compaction of Engineering cushions such as roads and airports.

4. There are single-axle single wheel, double-axle two-wheel, double-axle three-wheel and three-axle three-wheel arranged according to the wheel axle. Driven by internal combustion engine, mechanical or hydraulic transmission is used. General front wheel steering, good maneuverability, rear wheel drive.

5. Articulated steering structure and all-wheel drive are recommended to improve steering and rolling performance. The front wheel frame and frame are articulated to reduce body swing when the road surface is rough. The rear wheels are rigidly joined to the frame.

6. Steering is controlled by hydraulic pressure and Weggs cylinder. Scrapers are installed on both front and rear rollers to remove bonds from the rollers. There is also a water spray system for compacting the asphalt pavement by spraying water on the roller to prevent the asphalt mixture from sticking. In order to increase the force, iron, sand, water, etc. can be added to the grinding wheel to increase the pressure.