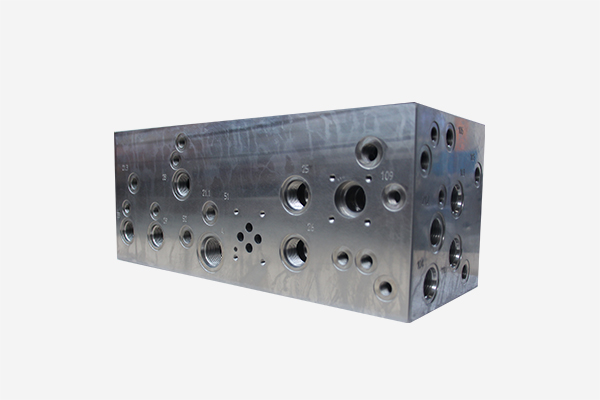

Method for detecting burrs in hydraulic valve blocks

Hydraulic valve block (abbreviated as hydraulic valve) is the control element in Hydraulic System, which is used to control the pressure,

flow rate and flow direction of fluid in hydraulic system so as to meet the requirements of different actions of various actuating elements.

Because of its compact structure, good sealing performance, convenient maintenance and technical confidentiality,

it is widely used in various hydraulic transmission systems.

The valve block is designed first and then machined. The machining process is roughly as follows:

(1) Pre-processing. Material for processing valve block needs to ensure compact internal structure without defects such as sandwich and trachoma. Blank inspection shall be carried out before machining. Cast iron and large steel blocks shall be aged and pretreated before processing.

(2) Blanking. Generally, at least 2 mm machining allowance is left on each side.

(3) Milling profile. Mill 6 sides of the valve block, leaving 0.2-0.4 mm rough grinding on each side.

(4) Rough grinding. Rough grinding 6 surfaces of valve block, leaving 0.05-0.08mm fine grinding quantity on each side, ensuring that the parallelism of each pair of corresponding surfaces is less than 0.03mm and the verticality of two adjacent surfaces is less than 0.05mm.

(5) Marking. Conditionally, it can be done directly with center drill on CNC drilling machine.

(6) Drilling holes. The surface roughness of each hole is Ra12.5.

(7) Fine grinding. Grind valve block 6 surfaces to roughness Ra0.4um.

Position tolerances must be strictly controlled during valve block machining to meet service requirements.

Reference to the following values for position tolerances:

https://www.saivs-industrial.com/products/hydraulic-manifolds/

The tolerance of verticality between the 6 surfaces of the valve block is 0.05mm; The tolerance of the parallelism of the relative plane is O.03mm; Flatness tolerance of each surface is 0.02mm; The tolerance of perpendicularity between the thread and its mating surface is 0.05mm; Allowance for all holes to be perpendicular to all faces is 0.05mm In order to ensure cleanliness of the hydraulic system, the hydraulic valve block must be deburred. At present, many manufacturers still use brushes to deburr manually, and some use methane blasting to deburr. Hydraulic valve block deburring shall be inspected by an industrial endoscope to ensure that the deburring is complete.

Clean valve block. Remove all particulate contaminants, corrosion, grease, etc. adhering to the valve block surface. To ensure that the valve block does not rust prematurely in service, it must be rust prevented. The internal oil passage of valve block can be acid pickled and phosphatized. The external rust prevention treatment process mainly includes surface treatment such as bluing, cadmium plating, galvanizing and nickel plating. However, in the process of hydraulic valve block machining, burrs often occur, which is especially harmful to the hydraulic system. Therefore, there are also relevant grading and evaluation rules for burr quality classification referring to surface roughness internationally. Therefore, in case of hydraulic valve block burrs, in order to ensure the cleanliness of the hydraulic system, relevant processes must be used to remove them.

How are burrs found inside the hydraulic valve block? Then it must be tested with an industrial endoscope. Through various processes and means, such as manual brush deburring, methane blasting and so on, after deburring, it needs to be inspected by industrial endoscope to ensure the deburring is completed.

At the same time, after the valve block has been used for a long time, it is also necessary to use industrial endoscope to detect the possible rust spots, oil hole iron chips, chips in the hole, impurities, etc. in order to clean the valve block as soon as possible and ensure the normal operation of the hydraulic valve block. Industrial endoscopes detect various particulate contaminants, corrosion, grease, etc. attached to the inner surface of the valve block. It can be said that inspection of hydraulic valve blocks and industrial endoscopes are indispensable inspection sharp tools.