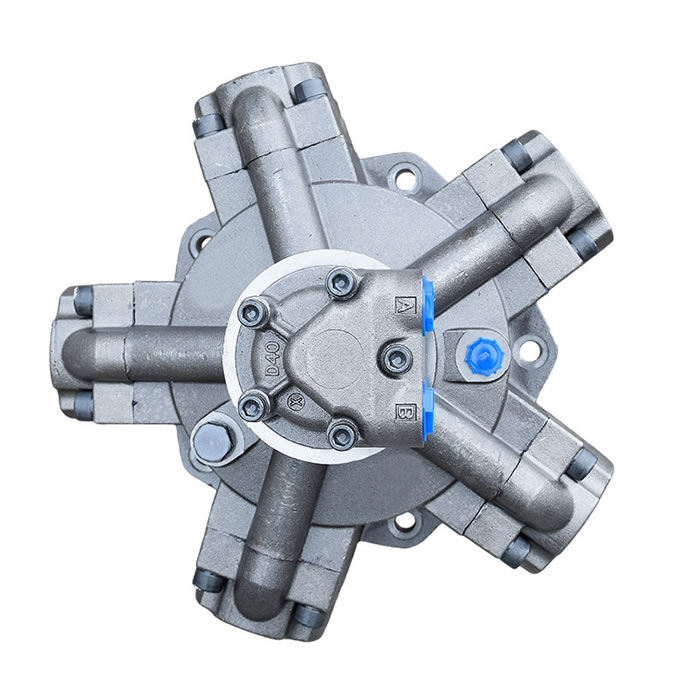

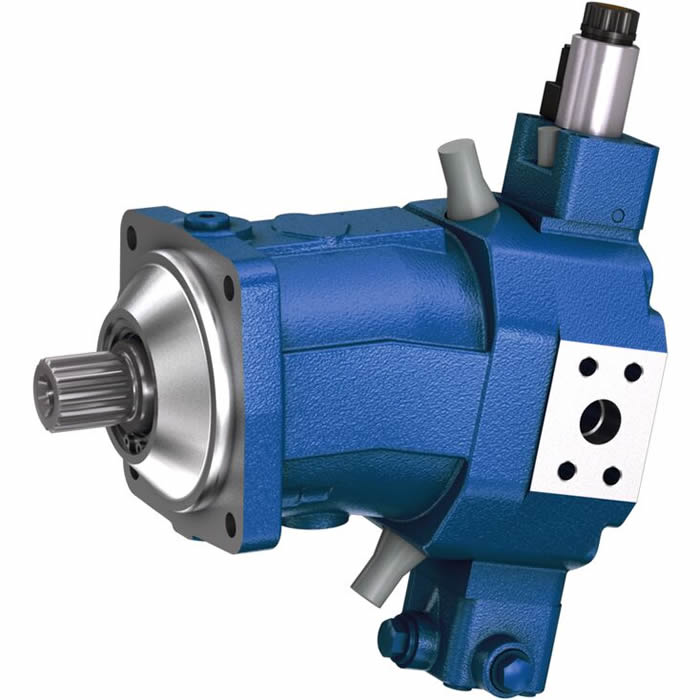

offers original and replacement QJM Series Motors Sphere Piston Hydraulic Motors for our customers. We will save customer costs, increase productivity and profit margins, Welcome to

Get Latest Price now!

Type: Hydraulic Motors

Structure: Hydraulic System

Displacement: 0.083-10.15L/r

Peak Pressure: 16-31.5MPa

Rotational Speed Range: 0.5-630r/min

Rated Output Torque: 123-15022N.m

Max. Power: 5-130Kw

Warranty:1 Year

Brand Name: SAIVS

Place of Origin:Ningbo,ZheJiang

Customized support:OEM,ODM

QJM hydraulic motor that can constitute a hydraulic actuator with different oil pumps, valves and hydraulic parts is able to adapt

itself to all kinds of mechanical conditions by reason of some measures taken to its design. The motor has many advantages, e.g.

light weight, small size, wide speed regulating range,capable of stepping variation, reliable performance and long useful life, etc.

It has been widely applied for mine engineering,hoisting transport, metallurgy, ships, machine tools, plastics processing and geological prospecting, etc.

It is mainly used for pedrail walking, driving railway wheels, different slewing gears, drilling, winch hoisting,

belt transmission,material agitation, cutting road surfaces, ship propulsion, plastics injection, etc.

QJM series hydraulic motor's structure principle:

The QJM hydraulic motor's oil distribution shaft is rigidly connected with the rear cover. The rotor block uses the oil distribution shaft as

radial support and employs a stator spherical rollaway nest and steel ball as axial support. The rotor's output shaft is an internal spline,

and the rotor block is floating. The oil distribution shaft is rigid, allowing the use of steel pipe connections for oil inlet and outlet.

Pressure oil is directed to the distribution port of each channel's high-pressure chamber by the variable valves, and then the pressure oil will

flow into each piston cylinder hole. Under the effect of pressure oil, the piston uses the ball with positive pressure N to affect the stator.

The stator, in turn, uses the same value number of reaction force N' to affect the steel ball. N can be divided into two components: radial and tangential.

The tangential force F, using the piston, acts on the rotor block. Driven by the tangential force F, the rotor block rotates around the oil distribution shaft.

At the same moment, there are a few pistons under the pressure oil effect, so it can produce large torque.

| Type | Displacement (L/r) | Pressure (Mpa) | Rotational Speed | Rated output Torgue | Max.power (Kw) |

| Rated | Peak | Range (r/min) |

| 1QJM001-0.08 | 0.083 | 10 | 16 | 8~500 | 123 | 5 |

| 1QJM001-0.10 | 0.104 | 10 | 16 | 8~400 | 154 | 5 |

| 1QJM002-0.2 | 0.2 | 10 | 16 | 5~320 | 295 | 8 |

| 1QJM01-0.1 | 0.1 | 10 | 16 | 8~800 | 148 | 10 |

| 1QJM01-0.16 | 0.163 | 10 | 16 | 8~630 | 241 | 12.5 |

| 1QJM01-0.2 | 0.203 | 10 | 16 | 8~500 | 300 | 12.5 |

| 1QJM02-0.32 | 0.326 | 10 | 16 | 5~400 | 483 | 13 |

| 1QJM02-0.4 | 0.406 | 10 | 16 | 5~320 | 600 | 13 |

| 1QJM11-0.32 | 0.339 | 10 | 16 | 5~400 | 468 | 20 |

| 1QJM1A1-0.4 | 0.404 | 10 | 16 | 5~400 | 598 | 20 |

| 1QJM11-0.5 | 0.496 | 10 | 16 | 5~320 | 734 | 20 |

| 1QJM11-0.63 | 0.664 | 10 | 16 | 4~250 | 983 | 20 |

| 1QJM1A1-0.63 | 0.664 | 10 | 16 | 4~250 | 983 | 20 |

| 1QJM12-0.8 | 0.8 | 10 | 16 | 4~250 | 1170 | 25 |

| 1QJM12-1.0 | 1 | 10 | 16 | 4~200 | 1480 | 25 |

| 1QJM12-1.25 | 1.33 | 10 | 16 | 4~160 | 1968 | 25 |

| 1QJM21-0.4 | 0.404 | 16 | 25 | 2~400 | 957 | 32 |

| 1QJM21-0.5 | 0.496 | 16 | 31.5 | 2~320 | 1175 | 32 |

| 1QJM21-0.63 | 0.664 | 16 | 31.5 | 2~250 | 1572 | 32 |

| 1QJM21-0.8 | 0.808 | 16 | 25 | 2~200 | 1913 | 32 |

| 1QJM21-1.0 | 1.01 | 10 | 16 | 2~160 | 1495 | 25 |

| 1QJM21-1.25 | 1.354 | 10 | 16 | 2~125 | 2004 | 25 |

| 1QJM21-1.6 | 1.65 | 10 | 16 | 2~100 | 2442 | 25 |

| 1QJM32-0.63 | 0.635 | 20 | 31.5 | 1~500 | 1880 | 80 |

| 1QJM32-0.8 | 0.808 | 20 | 31.5 | 1~500 | 2368 | 80 |

| 1QJM32-1.0 | 1.06 | 20 | 31.5 | 1~400 | 3138 | 80 |

| 1QJM32-1.25 | 1.295 | 20 | 31.5 | 2~320 | 3833 | 80 |

| 1QJM32-1.6 | 1.649 | 20 | 31.5 | 2~250 | 4881 | 80 |

| 1QJM32-2.0 | 2.03 | 16 | 25 | 2~200 | 4807 | 80 |

| 1QJM32-2.5 | 2.71 | 10 | 16 | 1~160 | 4011 | 62 |

| 1QJM32-3.2 | 3.2 | 10 | 16 | 1~125 | 4884 | 62 |

| 1QJM32-4.0 | 4 | 10 | 16 | 1~100 | 5920 | 62 |

| 1QJM42-2.0 | 2.11 | 20 | 31.5 | 1~320 | 6246 | 105 |

| 1QJM42-2.5 | 2.56 | 20 | 31.5 | 1~250 | 7578 | 105 |

| 1QJM42-3.2 | 3.24 | 10 | 16 | 1~200 | 4850 | 90 |

| 1QJM42-4.0 | 4 | 10 | 16 | 1~160 | 5920 | 90 |

| 1QJM42-4.5 | 4.6 | 10 | 16 | 1~125 | 6808 | 90 |

| 1QJM52-2.5 | 2.67 | 20 | 31.5 | 1~320 | 7903 | 130 |

| 1QJM52-3.2 | 3.24 | 20 | 31.5 | 1~250 | 9590 | 130 |

| 1QJM52-4.0 | 4 | 16 | 25 | 1~200 | 9472 | 130 |

| 1QJM52-5.0 | 5.23 | 10 | 16 | 1~160 | 7740 | 120 |

| 1QJM52-6.3 | 6.36 | 10 | 16 | 1~125 | 9413 | 120 |

| 1QJM62-4.0 | 4 | 20 | 31.5 | 0.5~150 | 11840 | 150 |

| 1QJM62-5.0 | 5.18 | 20 | 31.5 | 0.5~125 | 15333 | 150 |

| 1QJM62-6.3 | 6.27 | 16 | 25 | 0.5~125 | 14847 | 150 |

| 1QJM62-8.0 | 7.85 | 10 | 16 | 0.5~100 | 11618 | 121 |

| 1QJM62-10 | 10.15 | 10 | 16 | 0.5~80 | 15022 | 121 |

Flow rate of QJM motors=rated speed ×displacement

| Series | QJM001 | QJM01 | QJM11 | QJM12 | QJM21 | QJM32 | QJM42 | QJM52 | QJM62 |

| Flow rate L/min | 50 | 63 | 80 | 80 | 100 | 160 | 250 | 320 | 400 |

| Outer diameter(mm) | Ø140 | Ø180 | Ø240 | Ø240 | Ø300 | Ø320 | Ø350 | Ø420 | Ø485 |

|

|

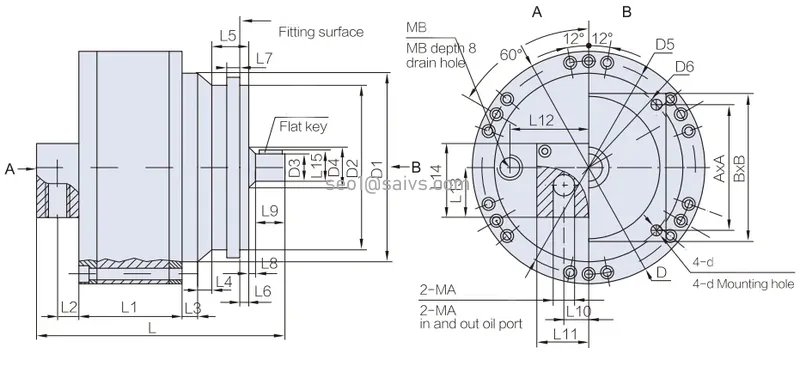

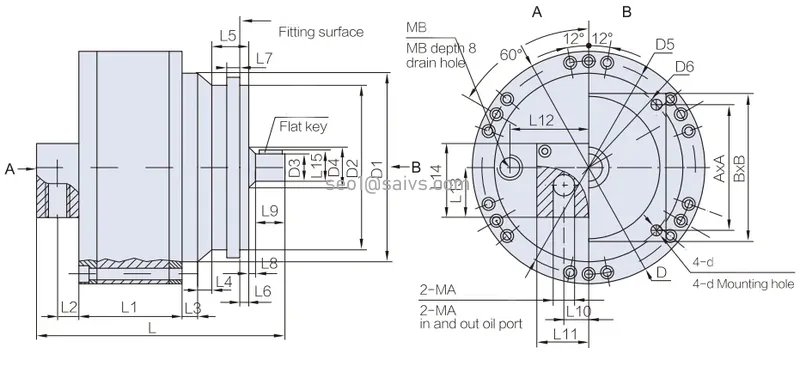

Installation

Model | L | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | L11 | L12 | L13 | L14 | L15 | D | D1 |

|

| D4 | D5 | D6 | d | In and out oil hole | drain hole | A×A | B×B | Flat Key |

kg |

| D2 | D3 | MA | MB | b×L |

| 10JM⁰01-**7 | 237 | 68 | 17 | 6 | 16 | 70 | 48 | 12 | 3 | 40 | 19 | 31.5 | 43 | 32 | 49 | 27.5 | φ141 | φ110 | φ75g7 | φ25h8 | φ35 | φ128 |

| φ11 | M18x1.5 | M12×1.5 | 70×70 | 90×90 | 8×36 | 10 |

| 1QJM002-**Z | 257 | 88 | 17 | 6 | 16 | 70 | 48 | 12 | 3 | 40 | 19 | 31.5 | 43 | 32 | 49 | 27.5 | φ141 | φ110 | φ75g7 | φ25h8 | φ35 | φ128 |

| φ11 | M18×1.5 | M12×1.5 | 70×70 | 90×90 | 8×36 | 12 |

| 1QJM02-**Z | 290 | 102 | 22 |

| 52 | 32 | 5 | 18 | 3 | 56.5 | 28 | 50 | 60 | 41 | 82 | 43 | φ180 |

| φ125g7 | φ40k6 | φ55 | φ165 | φ160 | φ13.5 | G3/4" | M14×1.5 | 113×113 | 140×140 | 12×45 | 24 |

| 1QJM11-**Z | 270 | 87 |

|

|

|

| 8 | 20 | 3 | 56.5 |

|

| 87 |

|

|

| φ240 |

| φ125g7 | φ40f7 | φ55 | φ220 | φ160 | φ13.5 | M33×2 | M16×1.5 | 113×113 | 142×142 | 12×45 | 40 |

| 1QJM12-**Z | 485 | 123 | 46 |

|

|

| 10 | 20 | 30 | 82 | 35 | 75 | 87 | 40 | 70 | 54 | φ240 |

| φ160h7 | φ50h7 | φ60 | φ220 | φ200 | φ18 | G1" | M16×1.5 | 141.5×141.5 | 178×178 | 14×72 | 70 |

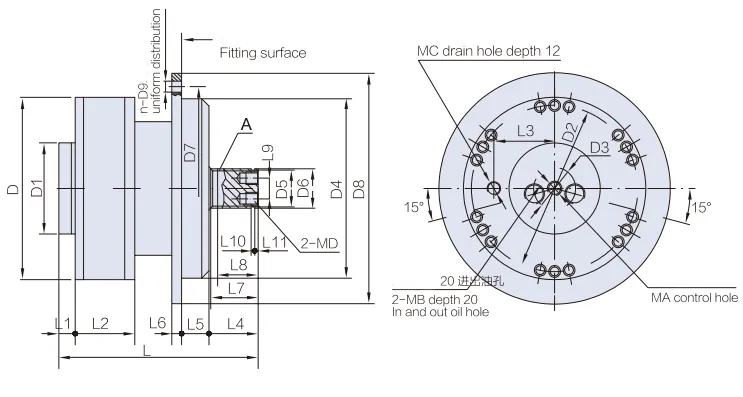

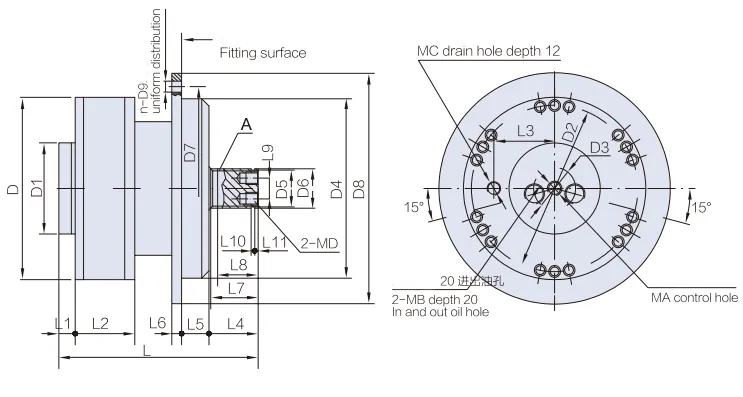

Model | L | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | L11 | D | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | n-D9 | MA | MB | MC | MD |

Flat key |

Spline A |

Weight

(kg) |

| QJM21-**Z3 | 328 | 26 | 99 | 100 | 81 | 55 | 16 | 78 | 66 | 38 | | | φ304 | φ150 | φ283 | φ69 | φ195f9 |

| φ65f⁷ | φ335 | φ379 | 6-φ18 | M12x1.5 | M33x2 | M22x2 | 2-M12depth20 | C18x75 |

| 75 |

| QJM21-**Ze3 | 378 | 26 | 113 | 100 | 81 | 38 | 16 | 78 | 66 | 38 | | | φ304 | φ150 | φ283 | φ69 | φ220f9 |

| φ65f7 | φ260 | φ300 | 6-φ18 | M12x1.5 | M33x2 | M22x2 | 2-M12depth20 | C18x75 |

| 80 |

| QJM32-*z | 395 | 24.5 | 144 | 115 | 101 | 30 | 25 | 100 | 70 | 40 | 2.65 | 3 | φ320 | φ165 | φ299 | φ79 | φ250f7 | φ79 | ①82b11 | φ300 | φ335 | 6-φ18 | M12x1.5 | M33x2 | M22x2 | 2-M12depth25 |

| 10-82b11x72b11x1269 | 106 |

| QJM32-**Z2 | 395 | 22 | 139 | 115 | 140 | 22 | 21 | 86 | 65 |

|

|

| φ320 | φ165 | φ299 | φ79 | φ340d9 | φ79 | φ92b11 | φ390 | φ430 | 6-φ17 | M12x1.5 | M33x2 | M22x2 | 2-M20depth20 |

| 10-82g6x72b12x1219 | 106 |

| QJM32-**Ze3 | 446 | 24.5 | 138 | 115 | 81 | 55 | 16 | 78 | 66 |

| | | φ320 | φ165 | φ299 | φ79 | φ295f9 |

| φ65f7 | φ335 | φ379 | 6-φ18 | M12x1.5 | M33x2 | M22x2 | M16

depth25 | C18x75 |

| 140 |

| QJM32-**Z3 | 363.5 | 24.5 | 138 | 115 | 81 | 55 | 16 | 78 | 66 |

|

|

| φ320 | φ165 | φ299 | φ79 | φ295f9 |

| φ65f7 | φ335 | φ379 | 6-φ18 | M12x1.5 | M33x2 | M22x2 | 2-M12depth25 | C18x75 |

| 108 |

| QJM52-**Z | 516 | 27 | 176 | 135 | 131 | 10 | 30 | 131 | 131 |

| | | φ420 | φ220 | φ360 | φ110 | φ295f7 |

| φ78h7 | φ340 | φ370 | 8-φ20 | M16x1.5 | M48x2 | M22x2 | M16

depth40 | C22x132 |

| 190 |

| QJM62-**Z | 487 | 42 | 162 | 165 | 157 | 5 | 20 | 155 | 152 |

|

| | φ485 | φ255 | φ435 | φ128 | φ40018 |

| φ101.55 | φ490 | φ530 | 8-φ22 | M16x1.5 | M48x2 | M22x2 |

| A25.4x120 |

| 240 |

Feature

1. Because the rolling body of this motor is replaced by a steel ball rather than two or more rollers and beams commonly used in inner curve Hydraulic Motors,

it is simple in structure, reliable in performance and greatly reduced in volume or weight.

2. A small kinematic pair inertia and a hard steel ball make this motor continuously work during the rotation at higher speed and under stronger impact load.

3. It has higher mechanical and volumetric efficiency for its small friction pair, oil feed shaft balanced with roller, piston pair capable

of static pressure balance & good lubrication and coated high pressure sealing oil on soft plastic mat.

4. As the oil feed shaft and stator are in rigid connection, the oil pipeline of this model can be connected with steel pipe.

5. As this model has variable displacements dual and trinal speeds, it is wider in speed regulating range.

6. Simple structure and easy maintenance.

7. The output shaft of the standard model can only endure the torque rather than outside radial and axial forces,

while that one of Z series hydraulic motor can endure outside radial and axial forces.

8. As T series hydraulic motor has a central through hole, the rotating shaft can pass through the motor.

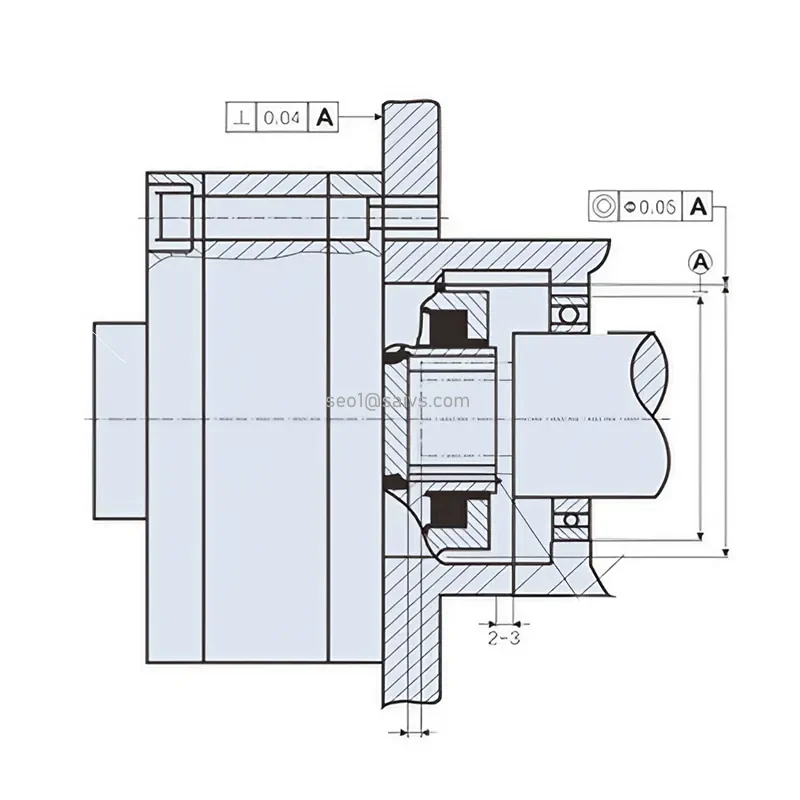

QJM Installation Requirements:

1. All types of hydraulic motors can be installed and used in any direction.

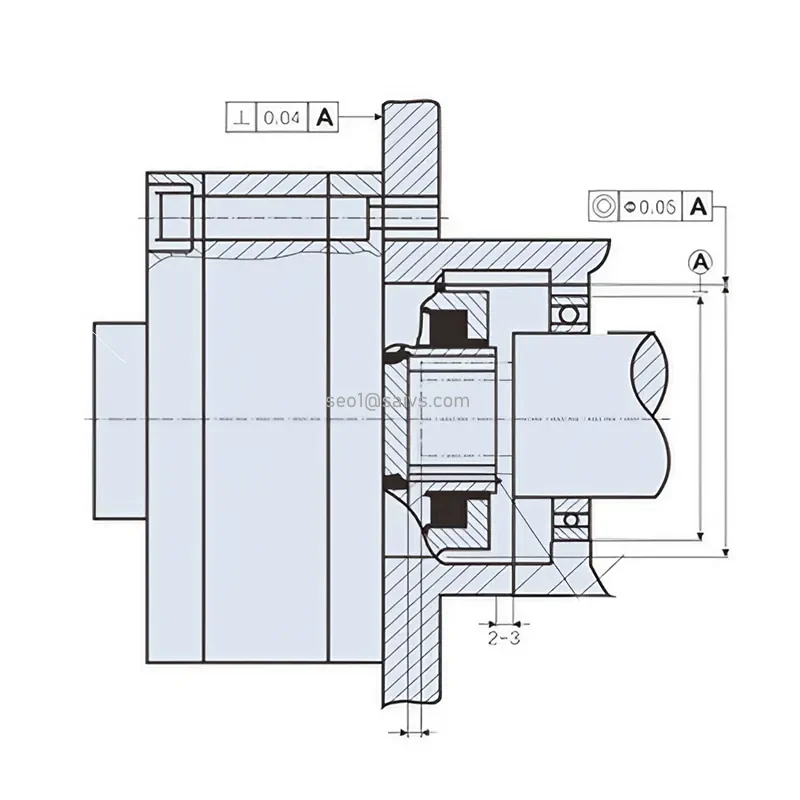

2. Due to the floating status of the rotor in the QJM motor, a 2-3 mm distance should be maintained before connecting the spline to ensure

unrestricted movement of the rotor in the shaft direction (as illustrated in the drawing). The splined hole of the motor and the splined

shaft of the operating mechanism should be aligned and kept in loose coordination. For technical requirements on the spline and locating seat, refer to the provided drawing.

3. After mounting the hydraulic motor in the machine and connecting the pipeline, turn the motor by hand or with a spanner.

The rotor should be flexible and free from blocks or imbalance.

4. Since the oil feed shaft and stator are in rigid connection, the oil pipeline of this model can be connected with a steel pipe.

Ensure that the leakage oil pipe:

- The top line of the drain pipe should be higher than that of the motor body to prevent oil storage emptying.

- The bore diameter of the leakage oil pipe and the joint should generally be larger than 12. The pipe can be directly connected to the oil tank.

If filtration is needed, use a separate strained oil filter. The pressure of the inner shell should not exceed 0.5 Mpa. For special requirements, please contact us.

6. Strictly maintain the cleanliness of the oil port and keep any solid particles away.

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our QJM Series Motors Sphere Piston Hydraulic Motors products solutions.

Request a Quote

Tags: QJM Sphere Piston Motor Sphere Piston Hydraulic Motor Hydraulic Motor