Understanding the Impact of Directional Control Valves on Oil Flow

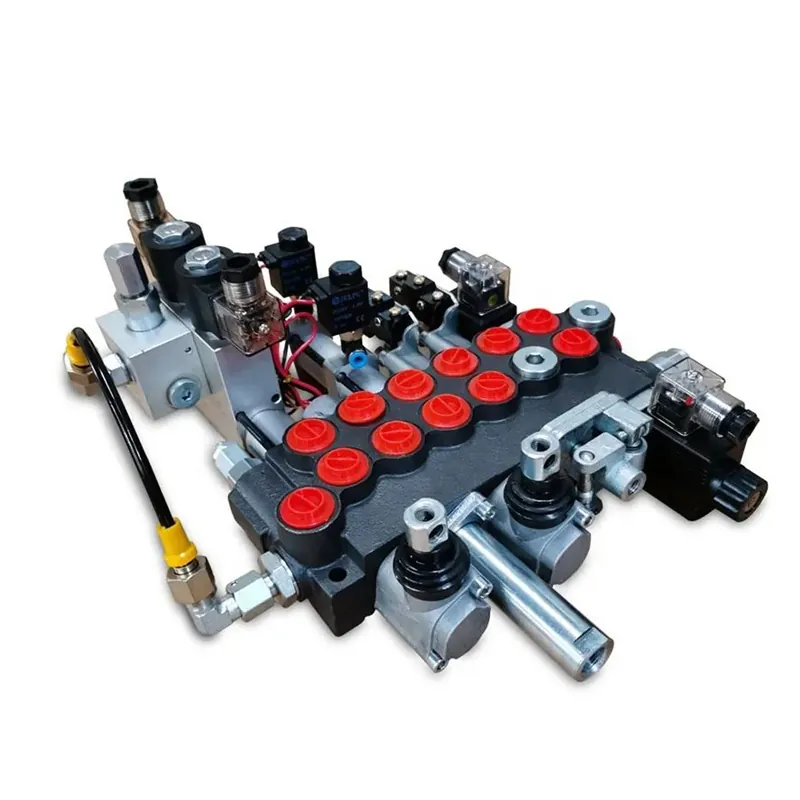

Directional control valves play a critical role in Hydraulic Systems, regulating the flow of oil to different components.

These valves determine the direction of fluid flow within a system, thereby enabling machinery to perform various functions.

Understanding how directional control valves affect oil flow is essential for optimizing hydraulic system performance and ensuring efficient operation.

Directional control valves primarily affect oil flow by controlling the direction of fluid movement within hydraulic systems.

These valves consist of various components such as spools, poppets, and seals, which work together to direct oil flow based on input signals from operators or automated control systems.

Key Components:

Spools: These are cylindrical components within the valve that move back and forth to open or close specific passages, thereby directing oil flow.

Poppets: Poppets are used in certain types of directional control valves to control the opening and closing of ports, regulating oil flow.

Seals: Seals prevent oil leakage and ensure proper functioning of the valve by maintaining a tight seal between moving parts.

Types of Directional Control Valves:

Spool Valves: Spool valves use cylindrical spools to control oil flow by positioning them within valve chambers to open or close specific ports.

Poppet Valves: Poppet valves utilize poppets, which are typically ball-shaped components, to control oil flow by seating or unseating them against valve openings.

Rotary Valves: Rotary valves use rotating mechanisms to control oil flow, with the rotation of the valve determining the direction of fluid movement.

Functions and Operation:

Directional control valves serve various functions within hydraulic systems, including:

-Reversing the direction of Hydraulic Cylinders.

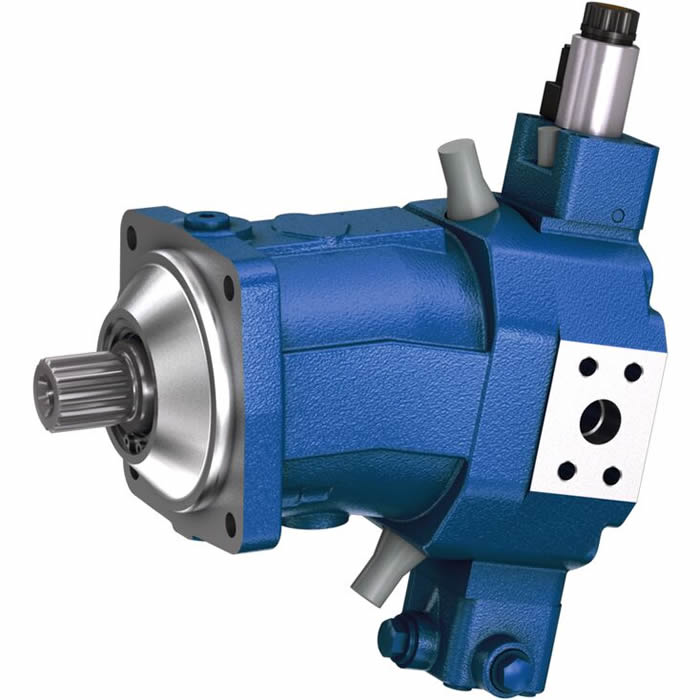

-Controlling the movement of Hydraulic Motors.

-Directing oil flow to different components of machinery.

The operation of directional control valves is based on input signals from operators or automated control systems,

which actuate the valves to open or close specific passages and direct oil flow accordingly.

This ensures precise control over hydraulic system operation, enabling machinery to perform desired tasks effectively.

Impact on Oil Flow:

The configuration and operation of directional control valves significantly impact oil flow within hydraulic systems.

Factors such as valve type, size, and design influence the rate and direction of fluid movement, affecting the overall performance of machinery.

Efficient oil flow management is essential for maximizing the efficiency and productivity of hydraulic systems.

Proper selection, installation, and maintenance of directional control valves are crucial for ensuring smooth oil flow, minimizing energy consumption, and preventing system failures.

In summary, directional control valves play a crucial role in regulating oil flow within hydraulic systems.

By controlling the direction of fluid movement, these valves enable machinery to perform various functions effectively. Understanding the impact of directional control valves on oil flow is essential for optimizing hydraulic system performance and ensuring efficient operation.