Tightening Bolts: Understanding Torque vs. Tension

Ensuring bolts are properly tightened is crucial for the integrity and safety of various machinery and infrastructure. This article explores the concepts of torque and tension, explaining their roles in tightening bolts and guiding you on which method to choose for specific applications.

Behavior of Tightened Bolts

When a bolt is tightened correctly, it utilizes its inherent elasticity. Similar to a spring that returns to its original shape after stretching, a bolt within its elastic limit will attempt to do the same when under load from a torque wrench or tensioner. This stretching creates a clamping force, which, combined with friction between the threads, secures the joint.

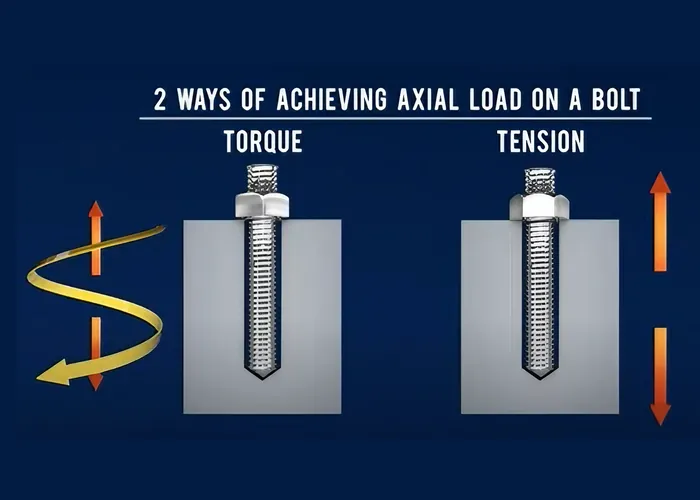

Understanding Torque and Tension

While often used interchangeably, torque and tension have distinct meanings:

Torque: Measured in Newton-meters (Nm), torque represents the twisting force applied when tightening a bolt using a wrench. A higher torque value typically translates to a greater clamping force exerted on the bolt indirectly through turning. Engineering specifications provide specific torque values to ensure proper clamping force without over-tightening or under-tightening the bolt.

Tension: Measured in Newtons (N), tension refers to the stretching force a bolt experiences, directly related to the clamping force holding the joint together. Unlike torque, which creates rotational motion, tension produces a linear pull along the bolt's axis. Achieving the correct tension is essential to avoid a loose or overly stressed joint, which could lead to bolt fatigue or breakage over time.

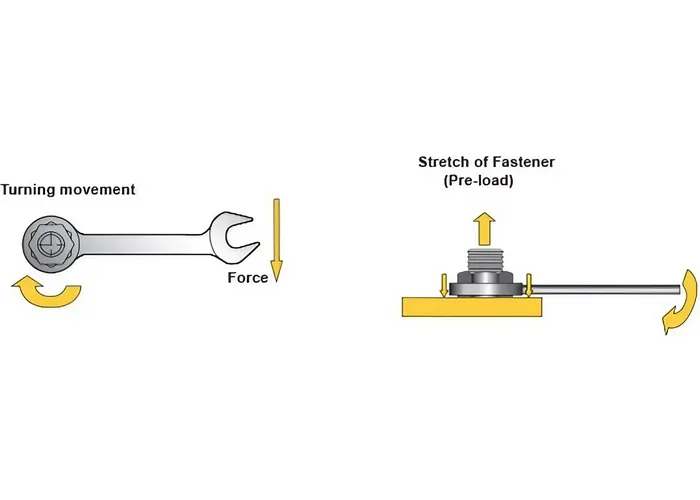

Torquing with Wrenches

Torque wrenches are designed to apply a specific amount of force to a fastener. They function based on Newton's third law, where an applied force generates an equal and opposite reaction. When a torque wrench is used, it stretches the bolt, creating the necessary clamping force. The wrench's handle length is crucial as it determines the amount of torque applied with a given force. A longer handle allows for more torque with the same effort. Manufacturers calibrate torque wrenches for accuracy, ensuring the applied force aligns with the desired torque settings.

Hydraulic Torque Wrenches: These tools take torquing a step further by utilizing hydraulic power to deliver a predetermined torque with exceptional precision. They are particularly valuable in situations requiring high torque values, reducing manual effort and enhancing consistency and reliability in bolting operations.

Friction and Torque

Friction is a significant factor in torquing a bolt. The applied torque is used for two main purposes: overcoming friction and stretching the bolt to achieve the desired clamping force. The coefficient of friction between the threads and the nut significantly affects the amount of torque required. An interesting fact is that only about 10-15% of the initial torque contributes to stretching the bolt, highlighting the significant force used to overcome friction rather than generating clamping force.

Manual vs. Hydraulic Torque Wrenches: For everyday tasks like changing a car tire, a handheld torque wrench is sufficient. These wrenches are designed for the torque ranges and precision needed in automotive applications and can be calibrated to match specific torque specifications. In contrast, industrial applications often demand significantly higher torque delivered with consistent precision. Hydraulically powered torque wrenches are vital in such settings, providing the necessary power to ensure each bolt is sufficiently and evenly torqued.

Hydraulic Tensioning

Hydraulic tensioning offers a sophisticated bolting method that employs hydraulic force to apply precise tension to fasteners. A hydraulic tensioner stretches the bolt to create the required tension for a secure joint without subjecting it to undue stress. This method is particularly advantageous for critical applications where exact clamping forces are paramount.

Tensioning Procedure

The tensioning process typically follows a standardized procedure:

Fitting the Tensioner: The tensioner is positioned over the bolt stud, ensuring proper alignment for even force distribution.

Applying Hydraulic Pressure: Hydraulic pressure is applied, stretching the stud to the required specifications.

Tightening the Nut: The nut is tightened against the joint face while maintaining hydraulic pressure to keep the bolt elongated.

Releasing Pressure: The pressure is slowly released, allowing the bolt to contract slightly while maintaining the clamping force.

Torque vs. Tension: Selecting the Right Method

The choice between torque and tension depends on various factors:

Criticality of Joints: Safety-critical joints might necessitate the precision of tensioning methods.

Accessibility: If easy access to joint components is limited, traditional torque tools might be the better option.

Available Equipment: Existing tools on-site can influence the decision; tensioning might require acquiring new equipment.

Number of Joints: For a large volume of joints, torque may be more efficient, while tensioning might be better for fewer, critical joints.

Budget: The cost of equipment and maintenance for each method needs to be considered.

Workforce Expertise: The skills and experience of the technicians should be factored in, as tensioning techniques might require specialized training.

Conclusion

Understanding the concepts of torque and tension is essential for properly tightening bolts. By considering the factors mentioned above, you can select the most appropriate method to ensure secure and reliable bolted joints in various applications.