Preventing Corrosion and Damage in Hydraulic Cylinders

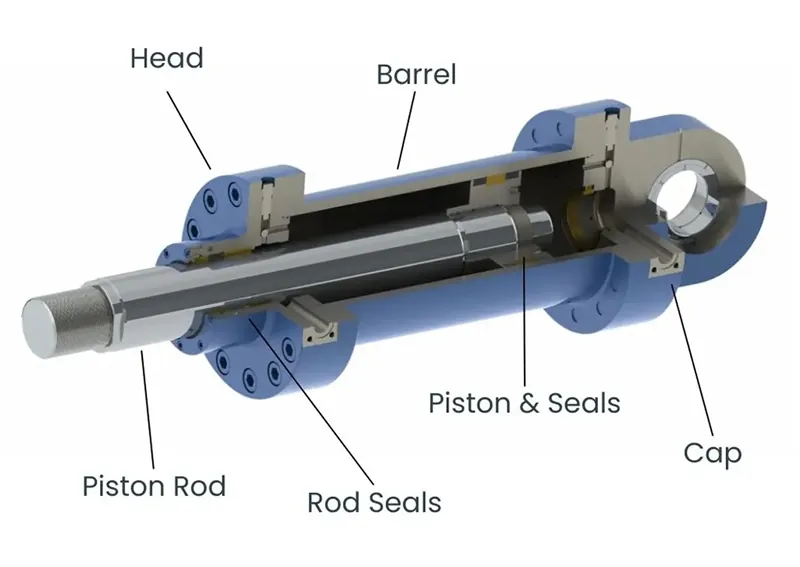

Hydraulic Cylinders are used in situations where heavier objects need to be supported for extended periods. Supporting heavier objects is safe even without hydraulic pressure. It is suitable for underwater, single-acting, load contraction, as well as self-locking nuts to ensure load safety. It is an easy to use, easy to control self-locking jack, especially in large projects. To ensure the safe working of the self-locking jack, a built-in pressure-reducing valve is used in the Hydraulic System for overload protection of the hydraulic system. The cylinder takes the flow and pressure of the fluid as input and linear velocity and force as output. The plunger of the hydraulic cylinder is capable of linear reciprocating motion with a certain linear displacement output. HydraulicA hydraulic cylinder is an energy conversion device that converts water energy into linear mechanical energy. A hydraulic cylinder is mainly composed of a cylinder the head, piston, piston, piston rod, and seals.

As the core component of hydraulic equipment, the main function of the hydraulic cylinder is to act as a hydraulic actuator. The working principle of a hydraulic cylinder is to convert hydraulic energy into mechanical energy. With the development and progress of science and technology, the wide application of hydraulic cylinder devices has led to rapid innovation and development. We take the initiative to find and solve practical problems, research and development, and innovation, to reduce costs, reduce losses, ensure safe production, and improve economic efficiency. In recent years, the domestic hydraulic cylinder supply and demand situation has changed greatly. For a long time, the contradiction between the supply and demand of Hydraulic Cylinders in China has been a troubling issue. “Overall insufficiency” becomes“structural insufficiency”

The plunger of the hydraulic cylinder will inevitably be corroded by oxidation and acidic gases when it is working, so it is necessary to apply appropriate grease on its surface to avoid corrosion or damage in the process of use. Secondly, dismantle the case to change the oil. In the long run, there will inevitably be impurities in the hydraulic cylinder, thus increasing friction. In addition, hydraulic oil has a certain period of use. If the oil is not changed for a long time, the hydraulic cylinder will be broken or corroded. It is better to prevent problems than to prevent them. Therefore, the rotation speed of the cylinder should be reasonably controlled so that it cannot exceed 2 meters per second to prolong the service life of the cylinder. In addition, it is also very effective to install an internal cushioning device on the hydraulic cylinder to protect it.

Conclusion

Hydraulic cylinders are important components in a variety of industrial applications, converting hydraulic energy into mechanical energy for linear motion. Despite their robustness and reliability, they require proper maintenance to ensure optimal performance and longevity. Regular tasks such as lubricating ram plugs, changing hydraulic fluid, and, controlling speed are essential to prevent corrosion, reduce friction, and extend the life of hydraulic cylinders. In addition, installing internal cushioning can further enhance protection against damage.