Pneumatic Torque Wrenches: Power Meets Precision in Manufacturing

Many industrial applications require fasteners to be tightened to precise torque specifications. While impact wrenches offer high torque, their lack of control can lead to over- or under-tightening. Pneumatic Torque Wrenches address this by providing both power and precision.

Understanding Pneumatic Torque Wrenches

Unlike impact wrenches that rely on hammering blows, pneumatic torque wrenches utilize a continuously engaged driveshaft and a controlled air motor. This mechanism allows for accurate torque application, crucial for ensuring joint integrity and preventing damage.

Types of Pneumatic Torque Tools:

Air Screwdrivers: Ideal for light-duty applications with low torque requirements (inch-pounds). They feature a disengaging clutch to prevent over-torquing upon reaching the set limit.

Pulse Tools: Designed for high-speed output in heavy-duty environments. They deliver significantly higher torque (over 330 lbf.ft) compared to air screwdrivers. A unique hydraulic mechanism allows the driveshaft to rotate freely until resistance is met, then applies force in pulses. This provides both high torque and user safety by mitigating kickback. Pulse tools are available with automatic shut-off or manual control.

Choosing the Right Form Factor:

In-Line: These compact, straight-line tools excel in flat workstation assembly due to their speed and output. However, they lack maneuverability for vertical surfaces or tight spaces.

Pistol Grip: Offering greater leverage for increased torque output, pistol grip tools are ideal for vertical fastening applications. Their bulkier design makes them less suitable for flat assemblies or confined areas.

Right-Angle: Providing versatility for both horizontal and flat assembly tasks, right-angle tools feature a 90-degree bend between the driveshaft and driver. While less powerful than pistol grip options, their extended handle allows for leverage in vertical applications.

Advantages of Pneumatic Torque Wrenches

Improved Efficiency: Significantly faster than manual tightening, pneumatic torque wrenches boost production line speed and reduce labor costs.

Precise Torque Control: With ±5% repeatability (up to ±2% with sensors), these tools ensure consistent and accurate fastening, crucial for product quality and safety.

Reduced Noise and Fatigue: Operating below 85 dB(A) and lacking impact, pneumatic torque wrenches create a quieter and more comfortable work environment, minimizing operator fatigue.

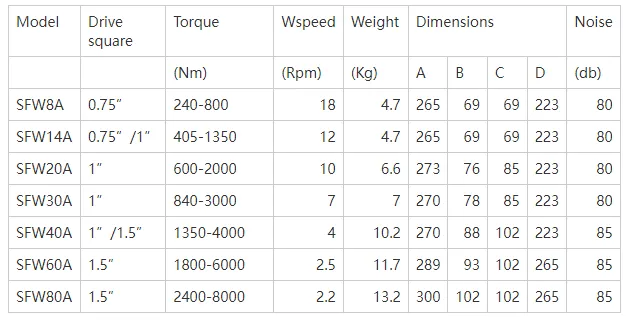

High Torque Capability: These wrenches can achieve maximum torque ratings exceeding 300,000 N⋅m, making them suitable for heavy-duty applications.

Versatility: Available in various form factors and torque ranges, pneumatic torque wrenches cater to a wide array of industrial needs.

Applications

Tightening/Removing Large Nuts: From truck tires to building steel frames and high-pressure connections, pneumatic torque wrenches efficiently handle large nuts.

Engine Components: These tools are crucial for tightening engine head nuts, injection heads on molding machines, and heat exchangers to precise specifications.

Heavy Vehicle Assembly: Nuts on car chassis and suspension components are prime candidates for pneumatic torque wrench application.

Continuous High Torque Tasks: Beyond nuts, these wrenches are valuable for operating ball valves, heavy equipment assembly, and reel adjustments in steel mills.

In conclusion, pneumatic torque wrenches are a vital category of industrial fastening tools. By combining controlled power with precise torque application, they ensure product integrity, improve assembly efficiency, and enhance operator safety in a wide range of manufacturing environments.

SAIVS offers a robust range of pneumatic torque wrenches designed to tackle demanding industrial fastening applications. These wrenches deliver exceptional power and precision, ensuring reliable joint integrity while maximizing productivity.