Hydraulic Vertical Lifting Wedge: A Powerful, Easy-to-Use Industrial Tool

The Enerpac LW16 Hydraulic Wedge Jack is a tool specifically designed for lifting and moving heavy equipment. Its compact size allows it to easily access tight spaces, and its powerful lifting force can effortlessly move heavy machinery. Additionally, it features a stable and reliable lifting process with a safe design, making it an ideal choice for various applications.

1.Compact Size, Easy Access to Tight Spaces

It boasts a compact and small design, enabling it to easily access tight spaces such as the narrow gaps between machines and equipment. This makes it an ideal choice for applications requiring lifting operations in confined spaces.

2.Powerful Lifting Force, Effortless Heavy Equipment Movement

Despite its small size, the Enerpac LW16 Hydraulic Wedge Jack possesses a powerful lifting force of up to 16 tons (157 kN). This allows it to effortlessly move heavy equipment such as machinery, vehicles, and construction components.

3.Stable and Reliable Lifting Process, No Slipping Risk

It features a unique interlocking wedge design that ensures a stable and reliable lifting process, eliminating the risk of slipping. This makes it ideal for applications requiring precise and safe lifting.

4.Single-Acting Spring Return Cylinder, Easy to Use

A single-acting spring return cylinder, making it simple and convenient to operate. Simply connect the hydraulic pump to the wedge jack, apply pressure to lift the equipment, and release the pressure to allow the wedge jack to retract automatically.

5.Includes Safety Block SB-2 for Safe Operation

The Enerpac LW16 Hydraulic Wedge Jack comes standard with the SB-2 safety block, which prevents the wedge jack from accidentally slipping. This ensures operator safety and reduces the risk of equipment damage.

6.Optional Step Block LWB-1 for Increased Lifting Height

Can be used with the optional LWB-1 step block, which increases the lifting height by 30 mm. This makes it even more suitable for applications requiring greater lifting heights.

Principle of operation

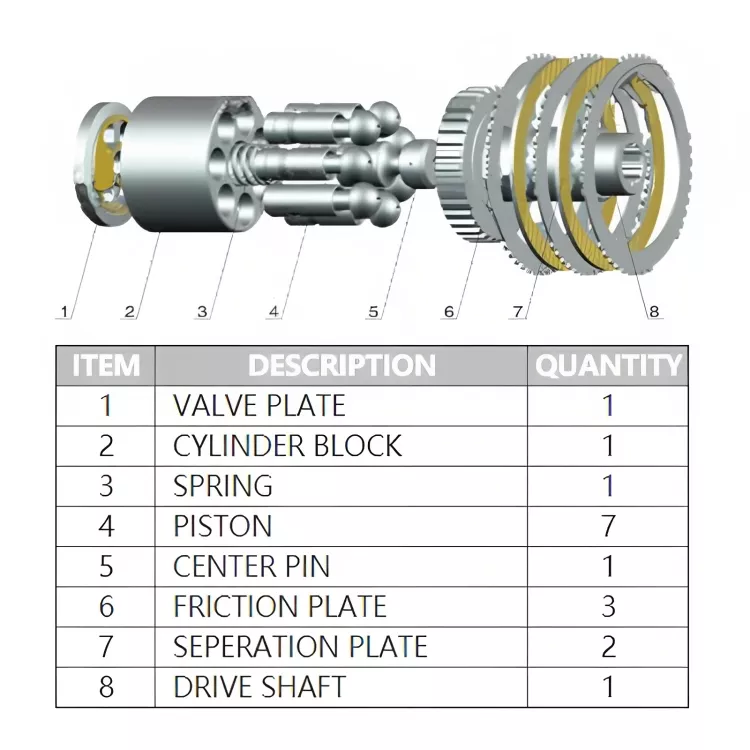

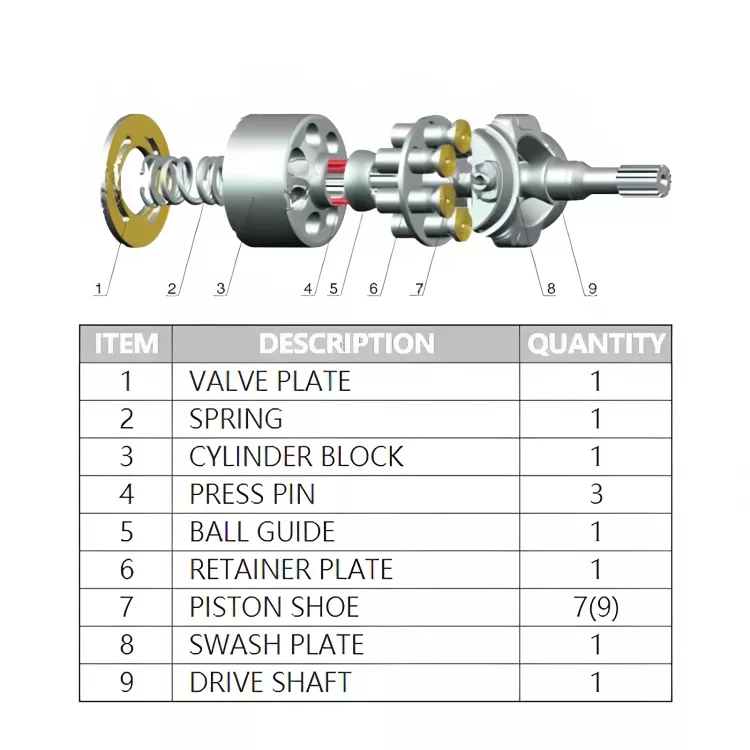

The hydraulic vertical lifting wedge works by utilizing hydraulic pressure to generate lifting force. The hydraulic vertical lifting wedge consists of the following main components:

Hydraulic Cylinder: The hydraulic cylinder is the core component of the hydraulic vertical lifting wedge, which consists of a cylinder, piston, piston rod, and seals. After the hydraulic oil enters the hydraulic cylinder, it will push the piston rod to move upward, thus generating the lifting force.

Wedge Lifter: The wedge lifter is mounted on top of the hydraulic cylinder and consists of a wedge block and a guide rail. The wedge moves upward under the guidance of the guide rails, thus transmitting the lifting force to the object being lifted.

HYDRAULIC PUMP: A hydraulic pump is used to provide hydraulic fluid. Hydraulic pumps can be manual or electric.

Safety devices: Safety devices are used to prevent accidental loss of control of the hydraulic vertical lifting wedge, such as safety valves and limit switches.

When a hydraulic vertical lifting wedge is used, the hydraulic pump delivers hydraulic fluid to the hydraulic cylinder. The hydraulic fluid pushes the piston rod upwards, which lifts the wedge. The wedge lifter transmits the lifting force to the object being lifted, moving it upward.

Maintenance of the hydraulic vertical lifting wedge

Regularly check the hydraulic fluid:

Check the level of hydraulic oil to ensure that the Hydraulic System has enough hydraulic oil.

Replace the hydraulic oil regularly to prevent contamination and aging of the oil and to ensure the normal operation of the hydraulic system.

Check and replace the filter element:

Regularly check the filter element of the hydraulic system to remove impurities and contaminants on the filter element.

Replace the filter element regularly according to the usage conditions and manufacturer's recommendations to ensure the cleanliness of the hydraulic fluid.

Inspect Hydraulic Cylinders and lines:

Check the seals and piston rods of the hydraulic cylinders to ensure that there are no leaks or wear.

Check hydraulic line connections to ensure no leaks, looseness, or damage.

Lubrication and corrosion protection:

Regularly lubricate wedges and other mechanical parts to reduce friction and wear.

Treat metal surfaces for corrosion to prevent rust and corrosion.

Inspect and maintain control systems:

Check control valves, sensors, and, electrical connections to ensure they are working properly.

Calibrate sensors and control systems regularly to ensure lift accuracy.

Regular Inspection and Testing:

Regularly carry out system testing to test the functions and performance of the hydraulic lifting wedge.

Problems are found during testing, and problematic parts are repaired or replaced promptly.

Through the above measures, the hydraulic vertical lifting wedge can be effectively maintained to ensure its stable operation and prolong its service life. If complicated problems are encountered in the maintenance process, it is recommended to consult professional technicians or the manufacturer's after-sales service.