How to Effectively Reduce Vibration and Noise in Plunger Pumps for Enhanced Performance

Plunger pumps are critical components in high-pressure Hydraulic Systems.

While their performance and reliability are widely recognized, one of the common challenges faced by industrial users is excessive vibration and noise.

These issues not only lead to operator discomfort and potential health hazards but can also result in environmental noise pollution and accelerated mechanical wear.

At Ningbo SAIVS Machinery Co., Ltd, we understand how essential it is to provide stable, quiet, and efficient hydraulic solutions. In this article, we highlight the key causes of vibration and noise in plunger pumps—and more importantly—how to address them through smart design, proper maintenance, and high-quality components.

1. Mechanical Sources of Vibration and Noise

One major contributor to noise is mechanical misalignment. When the pump shaft and motor shaft are not properly aligned or forcibly connected, the resulting imbalance generates abnormal vibration. Similarly, damaged bearings, faulty couplings, worn-out elastic pads, or loose bolts can create excessive mechanical noise.

At SAIVS, we recommend regular inspection and documentation of component vibrations, frequency levels, and acoustic measurements—especially for pumps operating at high speeds or handling large volumes. In cases where resonance occurs due to matching frequencies between the pump’s rotation and valve structures, adjusting the pump’s speed is an effective strategy to eliminate harmful resonance.

2. Hydraulic Noise from Internal Fluid Flow

Noise can also originate from inside the hydraulic system. Common causes include:

Undersized or blocked inlet pipelines

Clogged or underspec’d oil filters

Air entrainment in the suction line

Excessive fluid viscosity

Low oil levels causing cavitation

Hydraulic shock in high-pressure lines

To mitigate these issues, proper design of the reservoir is crucial. Equally important is selecting the right filter capacity, hose diameter, and directional valves.

SAIVS provides expert consultation and a complete range of precision-engineered plunger pumps and accessories that ensure smooth, silent operation—even in the most demanding conditions.

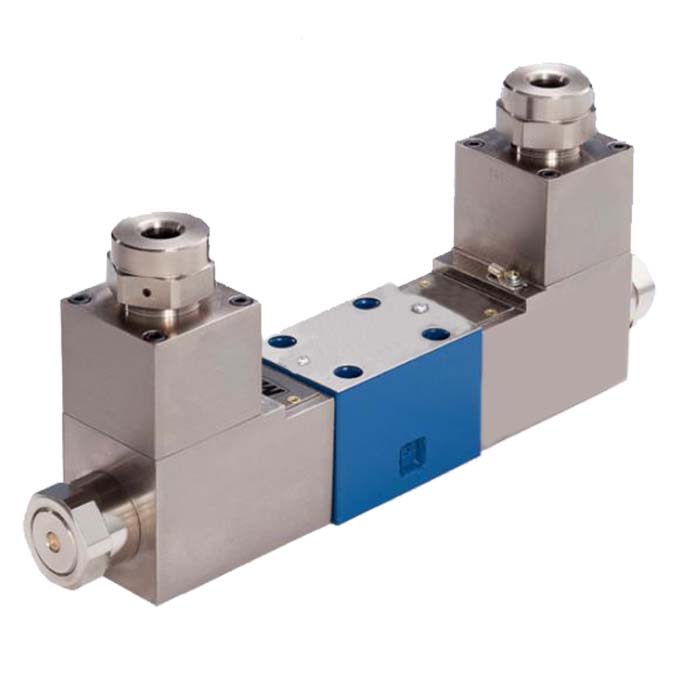

A4VG series rexroth hydraulic pump

Why Choose SAIVS?

With decades of experience, SAIVS Machinery offers not only premium-quality hydraulic components but also comprehensive support to our global customers.

We take pride in our advanced engineering, robust manufacturing standards, and dedicated after-sales service.

If you’re looking to improve the performance and reliability of your hydraulic systems, reduce operational noise, and enhance the working environment—contact SAIVS today. Our team is ready to help you select the ideal plunger pump solution for your application.