what is hydraulic piston pump

The hydraulic piston pump is the power component of the Hydraulic System. It is driven by the engine or motor, that is, the traditional electric hydraulic pump inhaled oil from the hydraulic tank to form a component of the pressure oil discharged and sent to the actuator. According to the structure, the hydraulic pump is divided into gear pump, plunger pump, Vane Pump and screw pump.

A hydraulic element that provides pressurized liquid for hydraulic transmission is one of the pumps. Its function is to transform the mechanical energy of a power machine, such as an electric motor and an internal combustion engine, into the pressure energy of a liquid. There are many factors affecting the life span of the hydraulic pump, in addition to the design and manufacturing factors of the pump itself, and the selection of some related components (such as couplings, oil filters, etc.), and the operation of the test running process.

is that the movement brings the change of the volume of the pump chamber, thereby compressing the fluid to make the fluid have pressure energy.

The necessary condition is that the pump chamber has a sealed volume change.

Types of common hydraulic piston pump:

1. according to whether the flow can be adjusted can be divided into: variable pump and fixed pump. The output flow can be regulated according to the requirement. It is called variable pump, and the flow can not be regulated as a quantitative pump.

2. according to the commonly used pump structure in the hydraulic system, it is divided into 3 types: gear pump, vane pump and plunger pump.

Gear pump: small volume, simple structure, less stringent requirements for the cleanliness of oil and cheaper price; but the pump shaft is unbalance, serious wear and greater leakage.

Vane pumps are divided into double acting vane pumps and single acting vane pumps. The pump has uniform flow, stable operation, low noise, higher working pressure and volume efficiency than the gear pump, and more complicated structure than the gear pump.

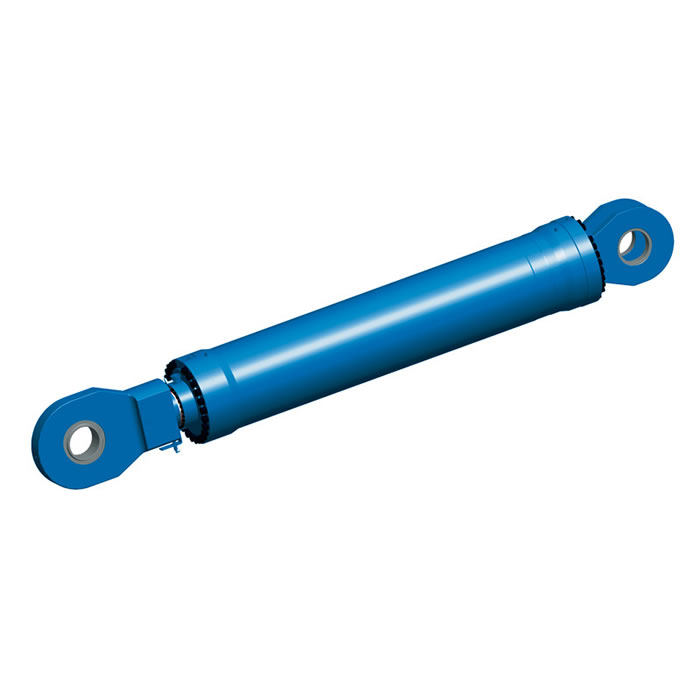

Plunger pump: high volume efficiency, small leakage, working under high pressure, mostly used in high power hydraulic system; but the structure is complex, the material and processing precision are high, the price is expensive, and the cleanliness of oil is high.

Piston pumps are usually used only when gear pumps and vane pumps fail to meet the requirements. There are also other forms of hydraulic piston pump, such as screw pumps, but the application is not as common as the above 3.Aluminum alloy, high strength, corrosion resistance, light weight, suitable for all kinds of environment.

The two-speed characteristic reduces the number of beating times, and in the low-pressure chamber is in the state of load diligence, immediately converted to high-voltage, shortening each operation cycle.

Equipped with pressure regulating valve, it can adjust control and set working pressure.