The Professional Expertise of Torque Bolt Sockets and Bolting Tools

In the intricate realm of mechanical engineering and construction, the significance of torque bolt sockets and bolting tools cannot be overstated. These specialized instruments play a pivotal role in ensuring the structural integrity and safety of various assemblies, from automotive components to industrial machinery and beyond. This article delves into the professional expertise required for effectively utilizing torque bolt sockets and bolting tools in diverse applications.

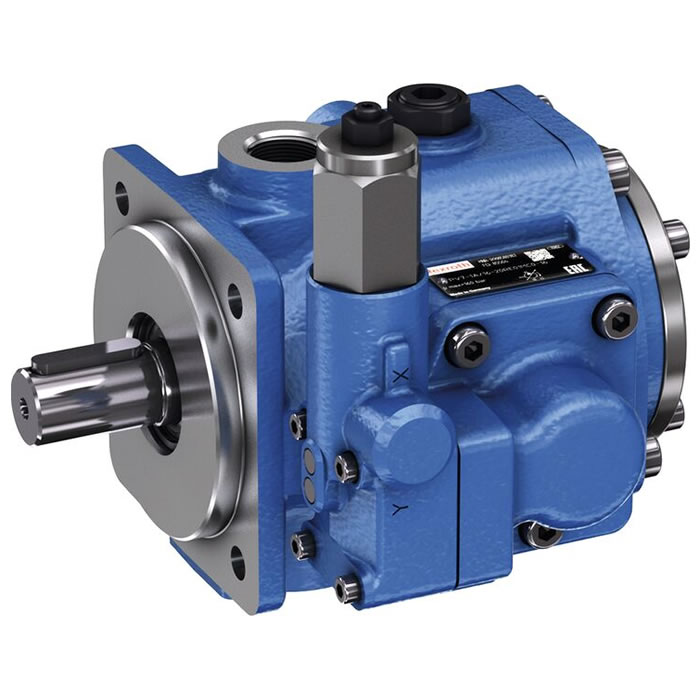

Torque bolt sockets, often crafted with precision and durability, are instrumental in applying the required torque to fasteners with accuracy and consistency. These sockets are engineered to withstand immense pressure and torque forces, ensuring seamless operation even in the most demanding conditions. Their design incorporates features such as robust material composition and precise sizing, enabling them to interface flawlessly with corresponding fasteners. This meticulous craftsmanship underscores the professional caliber demanded in the production and utilization of torque bolt sockets.

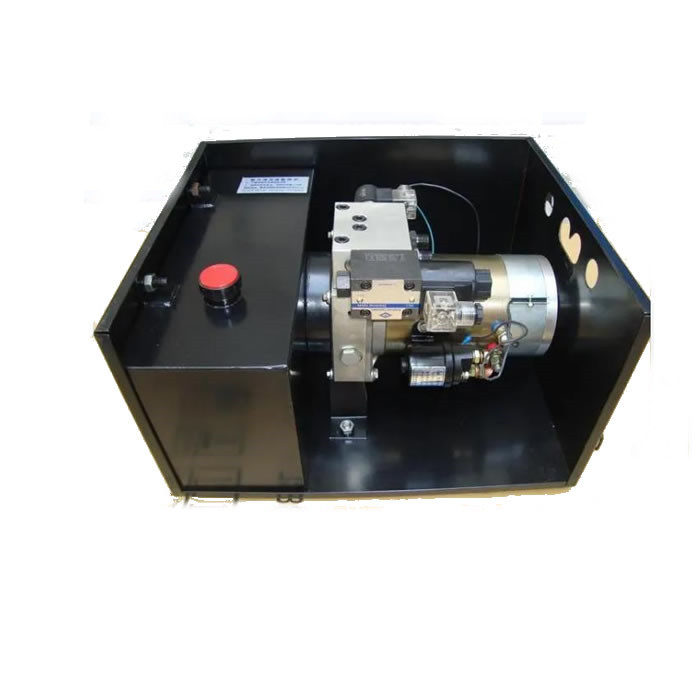

Furthermore, bolting tools encompass a spectrum of equipment tailored to the specific requirements of fastening tasks. From torque wrenches to Hydraulic Tensioners, these tools are designed to exert controlled force, facilitating precise tightening or loosening of bolts. The expertise in selecting the appropriate bolting tool for a given application is paramount, considering factors such as torque specifications, bolt size, and environmental conditions. Professional proficiency in bolting tools entails comprehensive knowledge of tool functionalities, safety protocols, and adherence to industry standards.

The deployment of torque bolt sockets and bolting tools extends across various industries, each with its unique set of challenges and specifications. In automotive engineering, for instance, these tools are indispensable in assembling critical components such as engines, transmissions, and suspension systems. The professional adeptness required in this domain encompasses not only the proficient use of torque bolt sockets but also the comprehension of torque specifications mandated by vehicle manufacturers.

Similarly, in the realm of construction and infrastructure development, bolting tools assume a crucial role in erecting structures with utmost stability and resilience. Whether it's securing steel beams in skyscraper construction or assembling intricate frameworks in bridge engineering, the utilization of torque bolt sockets and bolting tools demands a high level of expertise. Engineers and technicians involved in these endeavors must possess specialized knowledge in torque application techniques, bolt tensioning procedures, and the interpretation of engineering blueprints.

Moreover, the aerospace industry stands as a testament to the pinnacle of professional expertise required in the utilization of torque bolt sockets and bolting tools. Aircraft assembly and maintenance necessitate meticulous attention to detail and adherence to stringent safety standards. The deployment of bolting tools in this sector demands not only precision but also reliability, given the critical nature of aerospace components.

In conclusion, the professional expertise embodied in torque bolt sockets and bolting tools is indispensable across a myriad of industries. From automotive engineering to aerospace technology, the meticulous craftsmanship and technical proficiency required in utilizing these instruments underscore their significance in ensuring structural integrity and operational efficiency. As technology continues to evolve, so too will the demand for skilled professionals adept in the art of torque application and fastening techniques, reaffirming the indispensable role of torque bolt sockets and bolting tools in the fabric of modern engineering.