The Heart of the Machine: A Look Inside Hydraulic Cylinder Assembly

The Hydraulic Cylinder, a marvel of engineering, lies at the core of countless industrial applications. Its ability to convert hydraulic pressure into linear motion drives a multitude of machines. But how exactly does this powerful component come to life? Let's delve into the meticulous process of assembling a hydraulic cylinder:

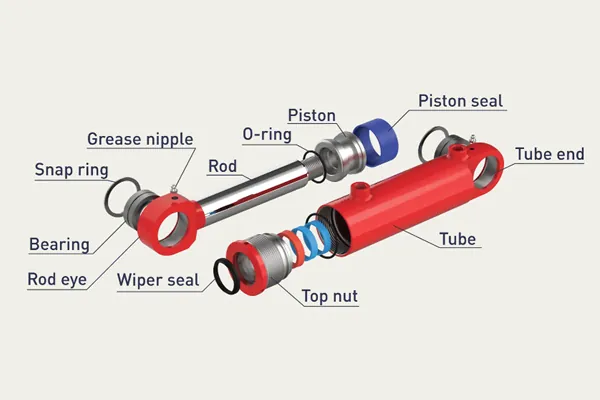

The Rod

The rod, with its smooth and polished surface, serves as a critical component in the hydraulic cylinder assembly. Its sleek design facilitates smooth movement within the cylinder, allowing for efficient operation in various applications. Crafted with precision, the rod undergoes meticulous polishing to ensure minimal friction and maximum durability, essential for withstanding the demanding conditions it will encounter during use.

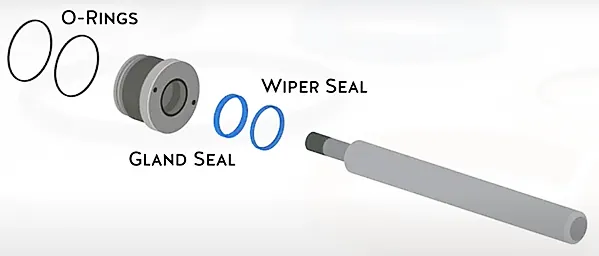

The Gland

The gland plays a pivotal role in the hydraulic cylinder assembly, acting as a housing for crucial components such as pressure seals while providing support to the rod during its movements. Precision-engineered, the gland is meticulously designed to withstand the pressures exerted within the cylinder, ensuring optimal performance and longevity. Its robust construction ensures stability and reliability, essential for maintaining the integrity of the Hydraulic System.

The Seals

Seals are indispensable components fitted within the gland to prevent leakages and safeguard against external contamination. Engineered with precision, these seals form a tight barrier, effectively sealing off the internal components from external elements such as dust, debris, and moisture. Their resilience and durability ensure the longevity of the hydraulic cylinder, enhancing its efficiency and reliability in diverse operating environments.

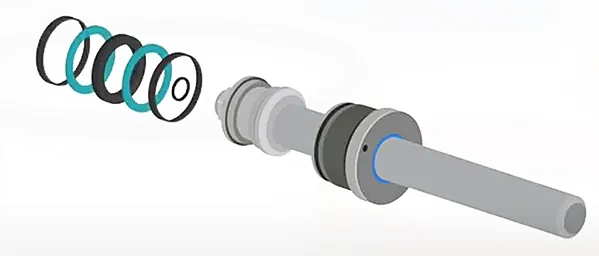

The Gland Is Fitted To The Rod

The precise fitting of the gland to the rod is a crucial step in the assembly process, ensuring proper alignment and functionality of the hydraulic cylinder. Carefully calibrated to exact specifications, this integration ensures a secure connection between the rod and the gland, minimizing any potential for misalignment or instability during operation. The seamless integration of these components is essential for the smooth and efficient functioning of the hydraulic system.

The Piston Is Then Fitted To The End Of The Rod

With meticulous precision, the piston is carefully affixed to the end of the rod, completing a vital stage in the assembly process of the hydraulic cylinder. This seamless integration ensures a secure attachment, enabling the piston to effectively transmit hydraulic force within the cylinder. Engineered for durability and performance, this assembly plays a critical role in facilitating the movement and functionality of the hydraulic system in various applications.

A Locking Nut Is Used To Hold The Piston In Place

To secure the piston firmly in its position, a locking nut is employed, providing a dependable fastening mechanism essential for the stability and reliability of the hydraulic cylinder. This meticulously engineered component ensures that the piston remains securely attached to the rod, even under high pressures and intense operating conditions. Its robust design and precise threading offer a steadfast grip, safeguarding against any potential loosening or dislodgment during operation.

Piston Seals Are Fitted To The Piston To Create A Seal Against The Cylinder Wall

The installation of piston seals onto the piston is a critical step in the assembly process, essential for maintaining the integrity and efficiency of the hydraulic cylinder. These seals are meticulously crafted to form a tight barrier against the cylinder wall, preventing any leakage of hydraulic fluid and ensuring optimal performance. Engineered for resilience and durability, these seals withstand the rigors of operation, effectively sealing off the internal components from external contaminants, thereby prolonging the lifespan of the hydraulic system.

Position The End Cap And Port For Welding Onto The Cylinder

With precision and accuracy, the end cap and port are positioned for welding onto the cylinder, marking a crucial stage in the assembly process. This meticulous alignment ensures a seamless integration of these components, guaranteeing structural integrity and leak-free operation. The welding process binds these components securely, creating a robust enclosure for the hydraulic system, capable of withstanding the pressures and demands of diverse applications.

The Fully Assembled Rod Is Then Inserted Into The Cylinder

With meticulous care, the fully assembled rod is inserted into the cylinder, culminating in the completion of the hydraulic cylinder assembly process. This final integration ensures the proper alignment and functionality of the hydraulic system, readying it for deployment in various industrial applications. The precision engineering and attention to detail throughout the assembly process guarantee optimal performance, reliability, and longevity of the hydraulic cylinder, meeting the demands of modern hydraulic systems.

Hydraulic Cylinder Wash Process

Place Cylinder Tubes on the Wash Tank Properly:

Ensure the cylinder tubes are correctly positioned on the wash tank for thorough cleaning and inspection.

Inspect Barrels for Burrs on Port Holes and Mouth of the Barrel:

Carefully examine the barrels for any burrs or sharp edges around the port holes and the mouth of the barrel. Burrs have the potential to damage pistons and gland seals or hinder the proper assembly of parts.

Deburr as Required:

Utilize appropriate tooling to remove any identified burrs or sharp edges. This step is crucial to ensure the integrity of the components and the effectiveness of the assembly process.

Rinse Inside of Tubes Using Cleaning Detergent:

Please make sure to rinse the inside of the tubes using a suitable cleaning detergent, ensuring thorough saturation of the barrel or tube with the fluid. This step helps remove any internal contaminants and prepares the surface for further cleaning.

Blow Tubes Out with Airline and Proper Wand:

Use an airline and proper wand to blow out any remaining debris from the tubes. Carefully inspect the wand to ensure it does not leave scratches on the barrel's inner diameter (ID), which could compromise its integrity.

Move Barrels Immediately to Assembly:

Once cleaning is completed and the barrels are deemed free of contamination, promptly move them to the assembly area to prevent any potential recontamination.

This detailed assembly process, characterized by precision engineering and meticulous attention to detail, ensures the optimal performance, reliability, and longevity of the hydraulic cylinder. It's a testament to human ingenuity, transforming raw materials into a powerful force that drives countless machines in our world.