Talking about the high pressure hydraulic system of tractor

At present, the large and medium-sized tractor market's largest amount of high-pressure Hydraulic System will be explained. I hope that it will help you to further understand the high-pressure hydraulic system of tractors and to operate correctly in spring ploughing.

The hydraulic suspension system of the tractor is mainly composed of three parts: cylinder, pump and valve. The cylinder here refers to the oil cylinder, the pump refers to the hydraulic pump (commonly used gear pump), and the valve refers to the distributor or multi-way valve. Due to the different positions and combinations of the three components in the hydraulic system, the hydraulic system is often divided into three categories: split hydraulic system, semi-split hydraulic system and integral hydraulic system.

The split hydraulic system, the strong pressure hydraulic system we are going to talk about today, uses a strong pressure distributor. The high-pressure hydraulic system is currently the most widely used hydraulic system on domestic medium and high-horsepower tractors. As well as the different positions where the fuel tanks are installed, they are connected to each other with fuel pipes.

The distributor handle of the strong pressure hydraulic system generally has four positions, namely: lift, neutral, pressure drop, and float. The function of the pressure drop position is the so-called strong pressure function. When the handle is moved to the pressure drop position, the double-acting The upper chamber of the lifting cylinder enters oil and the lower chamber returns oil. The farm implements are lowered under the action of the pressure oil, and the farm implements are forced to descend. The soil penetration performance of the farm tools such as the plow and the rotary tiller is very good. , In use, the rear wheel of the tractor may even be pushed up by the agricultural implement under the action of strong pressure, and the tractor cannot move forward. What’s more, users complain about this, which makes people laugh and cry, but it also reflects the strong pressure operating system from another side. There are indeed some insurmountable flaws.

The strong pressure distributor is not positioned at the pressure drop position, that is to say, when you move the handle to the pressure drop position, the tractor clamp will drop. When your hand is released, the handle will automatically return to the neutral position, which cannot be automatically remain at the pressure drop position. The failure to locate the pressure drop position is not the fault of the high pressure distributor, but the design is like this. This is actually a self-protection function of the tractor, and it is also convenient to operate. Otherwise, the rear wheel of the tractor mentioned above will be damaged during use. The phenomenon that the tractor cannot walk may increase significantly as it is lifted off the ground. The remaining three positions of the control handle of the strong pressure distributor: lifting, neutral, and floating all have positioning functions. After the hand is released, the control handle can be positioned at this position and does not move. Among them, in the lifting position, it has the function of automatic reset after lifting, that is After the farm implement is lifted to the highest position, the joystick can automatically jump back to the neutral position, while the handle has no automatic jumping function in the floating position and the neutral position.

The high-pressure hydraulic system adopts a split structure for its components, which is easy to arrange, and can easily use dual oil cylinders to improve the lifting capacity. The favor of tractors, at present, most of the domestic large and medium horsepower tractors use mechanical strong pressure hydraulic system. On the contrary, the semi-split hydraulic system and integral hydraulic system of the mechanical non-strong pressure system are relatively rarely used. Although the electro-hydraulic integrated electro-hydraulic control system has been promoted for many years, due to many failures, unstable quality and high price, it has been It has not been recognized by the market, and it is still in the stage of promotion and trial, and the number is very small. However, as the future development direction of tractor hydraulics, the electronically controlled hydraulic control system should be well prepared for technical reserve work, continue to be introduced to the market, gradually accumulate experience, continuously improve, and continuously improve the reliability of its work and ensure product quality.

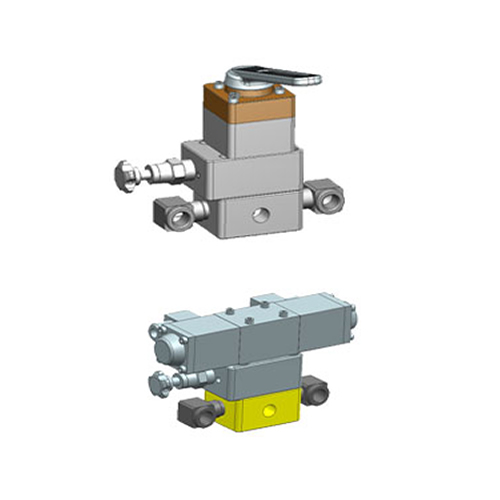

In the use of tractors, whether the strong pressure system is better or the non-strong pressure system is better, in fact, it has always been controversial. In fact, the strong pressure system has always been criticized in the market. After buying a strong pressure tractor, many users took the initiative to use it. Changed to non-pressure type. In fact, the change is also very simple. Connect the upper chamber oil pipe of the double-acting Hydraulic Cylinder with the fuel tank, so that the oil in the upper chamber of the cylinder can flow directly back to the fuel tank. At this time, the strong pressure effect of the tractor disappears. Tractor manufacturers are also advancing with the times. In order to meet the market demand, this function is also installed on the tractors that leave the factory. An oil pipe is connected to the oil tank from the upper chamber oil pipe of the tractor double-acting oil cylinder, and an oil pipe is installed. The control valve is manually controlled by the handle. When the handle is moved to the closed position, the upper chamber oil circuit of the double-acting oil cylinder is not connected to the fuel tank. At this time, the tractor has a strong pressure function; when the handle is moved to the open position, the double-acting The oil circuit of the upper cavity of the oil cylinder is connected with the oil tank, and the oil is directly returned to the oil tank, and the tractor does not have a strong pressure function.