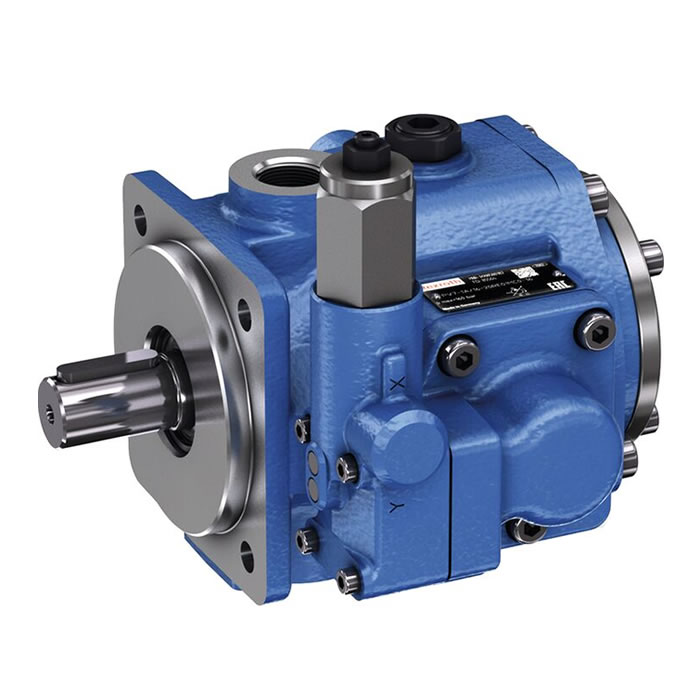

SAI Series Radial Piston Hydraulic Motor Repair Manual

I. SAI Series Radial Piston Hydraulic Motor Product Overview

The SAI GM Hydraulic Motor, part of the GM series (GM05/GM1/GM2/GM3/GM4/GM5/GM6/GM7/GM9), is a robust radial piston hydraulic motor

designed for efficient and powerful performance.

Produced by SAIVS, this motor is constructed from high-quality cast iron, making it resilient and suitable for demanding industrial conditions.

With a nominal pressure resistance of 25MPa and a working pressure range of up to 40MPa, it demonstrates durability and versatility in handling a wide

range of hydraulic pressures.

Controlled through pressure flow control, the motor allows for precise management of hydraulic systems.

It comes with a 1-year warranty, providing users with reliability and peace of mind. The minimum order quantity is 1 piece,

and the supply ability is 1000 pieces per month, ensuring accessibility and availability to meet various industrial demands.

Application:

Industrial Machinery

Construction Equipment

Agricultural Machinery

Marine applications

Material Handling Equipment

Mining Equipment

Automotive Industry

Energy Sector

Oil and Gas Industry

Specialized Machinery

II. Tools needed for SAI hydraulic motor repair:

Allen wrench

Screwdriver

III.Safety Instructions

- Always wear safety glasses when working on Hydraulic Motors.

- Disconnect the power supply to the motor before beginning any work.

- Release any residual pressure in the Hydraulic System before beginning any work.

- Use the correct tools for the job.

- Follow the manufacturer's instructions carefully

IV.Disassembly Process

- Remove the motor from the application.

- Drain the hydraulic fluid from the motor.

- Remove the bolts or screws that hold the motor together.

- Separate the motor housing from the rotor assembly

V.Cleaning and Inspection of SAI Series Radial Piston Hydraulic Motors

Repair Procedures and Safety Precautions:

SAI Series radial piston hydraulic motors are known for their durability and reliability. However, like any mechanical device,

they require regular cleaning and inspection to maintain optimal performance and prevent premature failure.

Before you begin cleaning and inspecting your SAI Series radial piston hydraulic motor, it is important to take the following safety precautions:

a. Wear safety glasses and gloves at all times. Hydraulic fluid can be harmful if it comes into contact with your skin or eyes.

b. Relieve pressure from the hydraulic system before disassembly. This can be done by opening the pressure relief valve or by disconnecting the

hydraulic lines.

c. Place the motor in a clean, dry, and well-ventilated area. This will help to prevent contamination and ensure that you have a good workspace.

d. Have all necessary tools and supplies on hand. This will help to avoid delays and ensure that the job is done efficiently.

Cleaning Procedure:

a. Disassemble the motor. Refer to the SAI Series radial piston hydraulic motor service manual for specific disassembly instructions.

b. Clean the external components. Use a cleaning solvent and a lint-free cloth to remove dirt, grease, and debris from the external components of the

motor.

Be careful not to get any cleaning solvent into the internal components of the motor.

c. Clean the internal components. Use mineral spirits and compressed air to clean the internal components of the motor. Be careful not to damage any of the seals or bearings.

d. Inspect the components. Once the motor is clean, carefully inspect all of the components for signs of wear or damage.

Pay particular attention to the following:

The piston rings and cylinder walls: Look for scoring, scratches, or excessive wear.

The bearings: Look for signs of wear, pitting, or scoring.

The seals: Look for cracks, leaks, or damage.

Replace any worn or damaged components. If you find any worn or damaged components, they must be replaced before reassembling the motor.

*Tips

- When cleaning the internal components of the motor, be sure to blow out all of the compressed air before reassembling the motor.

- Do not use harsh chemicals or abrasives to clean the motor, as this can damage the components.

- If you are unsure about any of the cleaning or inspection procedures, consult a qualified hydraulics technician.

By following these steps, you can help to ensure that your SAI Series radial piston hydraulic motor continues to operate safely and efficiently for many

years to come.

SAIVS technical support and contact information

Q: What about your quality control?

A: 1. Checking the raw materials after they reach our factory(IQC) 2. Checking the details before the production line operated.

3.Have full inspection and routing inspection during mass production(IPQC) 3. Checking the goods after they are finished(FQC).

4. Checking the goods after they are finished(QC). 5.100% inspection and delivery before shipment

Q: What if there is a problem with the purchased product?

A: If any quality problem happens please take some photos and videos to show the exact problem, then our engineer will judge and give a solution.

Q: SAI Series Hydraulic Motor Shipping Process

A: If you are interested in shipping information for our products, please check the following two articles:

① Log No. 4 SAI GM Series Hydraulic Motors For Taiwan Customers

② Log No. 13:SAI Series Radial Piston Hydraulic Motors To Australian Customer

If you need assistance in repairing your SAIVS hydraulic motor, please feel free to contact our customer service team.

We will do our best to provide you with professional and timely support to ensure that your repair goes smoothly.