Hydraulic Cylinder Validation Testing: Ensures safety, reliability, and performance

I. Hazards Associated with Hydraulic Cylinder Pressure Intensification

Hydraulic Cylinders are essential components in many industrial and mobile applications.

They utilize the principle of Pascal's law to transmit and amplify force, enabling the movement of heavy loads with relatively low control forces.

However, the high-pressure fluids used in Hydraulic Systems pose significant safety hazards if not properly managed.

The primary danger associated with hydraulic cylinder pressure intensification is the potential for uncontrolled release of stored energy.

When a hydraulic cylinder is pressurized, its fluid stores a significant amount of potential energy.

If a failure occurs in the cylinder, hose, or other system components, this energy can be released instantaneously, resulting in:

Violent expulsion of components: Rapid depressurization can cause parts such as pistons,

rods, and seals to be ejected with high force, posing a severe impact hazard to nearby personnel.

Damage to equipment and surroundings: The sudden release of high-pressure fluid can damage the cylinder and nearby equipment and infrastructure.

Loss of control and functionality: If a hydraulic cylinder fails, it can lead to a loss of control over the system it is actuating,

potentially causing machinery to malfunction or even collapse.

II. What Happens During Hydraulic Cylinder Validation Testing?

The proof pressure test involves fully extending the cylinder and holding pressure at 2500 psi

or as specified on the assembly print for at least 30 seconds. Rejection criteria include external leakage or structural deformation.

For double-acting cylinders, the process is repeated with full retraction.

The internal bypass test, conducted on double-acting cylinders, is performed alongside the proof pressure test.

The cylinder is fully extended, pressure is held at 2500 psi, and excessive piston seal bypass is assessed by removing the retract line.

The same procedure is applied during full retraction to evaluate piston bypass. Excessive bypass in either case leads to rejection.

It is essential to remove the hydraulic line, plug or cap the open line from the valve,

and consider specified criteria for cast iron rings and bypass rates during these tests.

III. Conducting a hydraulic cylinder proof test involves the following steps

Prepare the Hydraulic Cylinder:

Thoroughly clean the hydraulic cylinder, removing any debris or contaminants that may affect the test.

Set Up the Testing Equipment:

Connect the hydraulic cylinder to a pressure source, such as a pump, and properly calibrate the pressure gauge and other necessary equipment.

Apply Pressure Gradually:

Gradually increase the applied pressure on the hydraulic cylinder until it reaches the proof pressure,

typically set at 1.5 to 2 times the working pressure of the cylinder.

Hold the Pressure:

Maintain the hydraulic cylinder at high pressure for a specified duration, usually a few minutes,

to ensure it can withstand the maximum pressure without any leakage or failure.

Inspect the Hydraulic Cylinder:

Release the pressure and thoroughly inspect the hydraulic cylinder for any damage or leakage.

Look for visible signs of failure, such as cracks, deformations, or leaks.

Document the Results:

Record the test results, including the proof pressure, the duration of pressure holding,

and any observations or issues identified during the test.

Repeat the Test if Necessary:

If the hydraulic cylinder fails the test, address the identified issues

and repeat the test to verify that the necessary corrections have been made.

Reinstall the Hydraulic Cylinder:

Once the hydraulic cylinder successfully passes the proof test, it can be reinstalled and returned to operational use.

By systematically following these steps, you can ensure a comprehensive proof test for hydraulic cylinders,

identifying and addressing any potential issues before returning the cylinder to service.

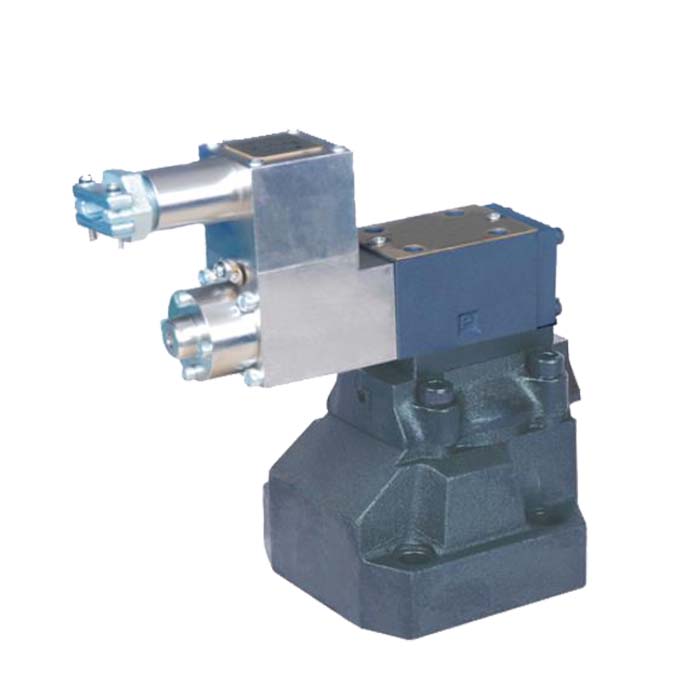

IV. SAIVS Hydraulic Cylinder Testing Services

SAIVS offers comprehensive hydraulic cylinder testing services to ensure the safety, reliability, and performance of your critical equipment.

Our experienced engineers utilize state-of-the-art testing facilities and equipment to perform a wide range of validation tests.

For additional details regarding hydraulic cylinders, feel free to contact us.