Hydraulic Cylinder/Jack - Understanding the Basics

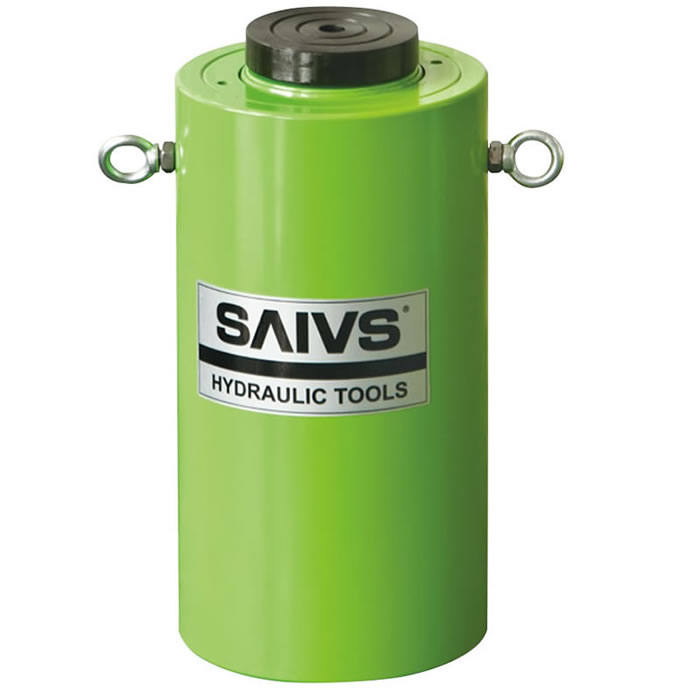

A Hydraulic Cylinder/jack is a mechanical actuator that uses hydraulic fluid pressure to convert the energy into linear motion. The basic components of a hydraulic cylinder/jack include a cylinder barrel, a piston, a piston rod, a gland, and end caps. The cylinder barrel is where the hydraulic fluid is stored, while the piston moves back and forth inside the barrel to generate force. The piston rod connects the piston to the load, and the gland ensures that the hydraulic fluid does not leak out.

There are different types of Hydraulic Cylinders/jacks available on the market, including single-acting, double-acting, telescopic, and multi-stage cylinders/jacks. Single-acting cylinders/jacks exert force in only one direction, while double-acting cylinders/jacks exert force in both directions. Telescopic cylinders/jacks are suitable for applications with limited space, while multi-stage cylinders/jacks are ideal for high force applications.

When selecting the right hydraulic cylinder/jack for your application, factors such as load capacity, stroke length, and operating pressure should be considered. It is also important to choose a cylinder/jack with the right mounting style and end fittings.

In summary, hydraulic cylinders/jacks are versatile actuators that can generate high force and have a wide range of applications in various industries. Understanding the basics of hydraulic cylinders/jacks is essential for selecting the right product for your application.