Hydraulic Bolt Torquing Machines: Precision Fastening Solutions for Industrial Applications

The Ultimate Guide to Hydraulic Bolt Torquing Machines for Precision Fastening

In heavy industries such as oil and gas, power generation, and construction, precision fastening is critical to ensuring safety, efficiency, and long-term performance.

Hydraulic bolt torquing machines have become the go-to solution for industrial torque applications due to their reliability and accuracy.

This guide will explore key aspects of these machines, including Square Drive Hydraulic Torque Wrenches and Low Profile Hydraulic torque wrenches, to help procurement professionals make informed decisions.

What is a Hydraulic Bolt Torquing Machine?

A hydraulic bolt torquing machine is a specialized tool designed to apply precise torque to fasteners, ensuring secure and uniform tightening.

These machines are widely used in applications where manual torque wrenches fall short due to high torque requirements or the need for extreme precision.

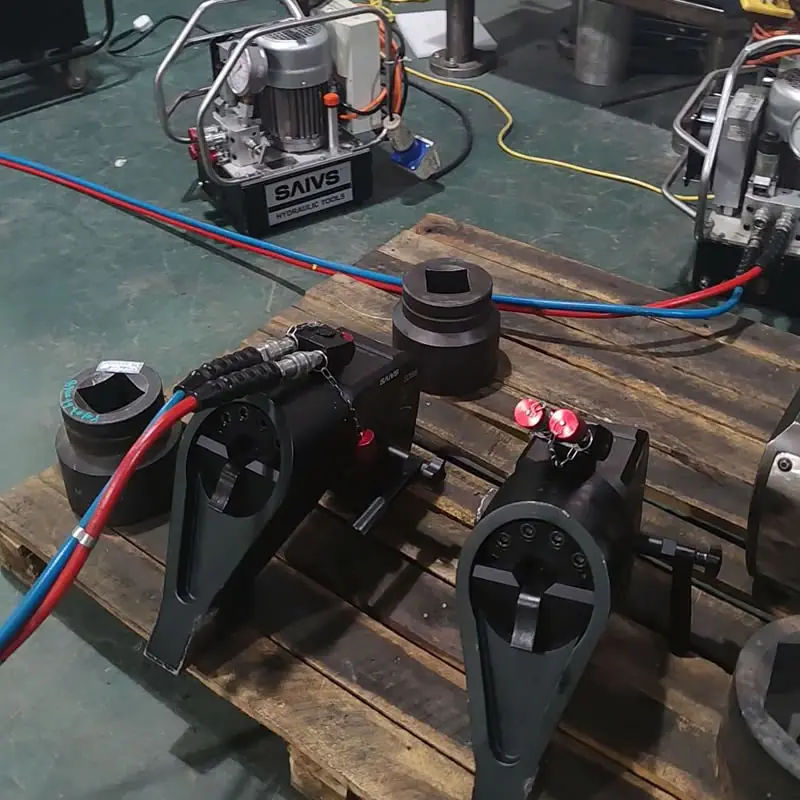

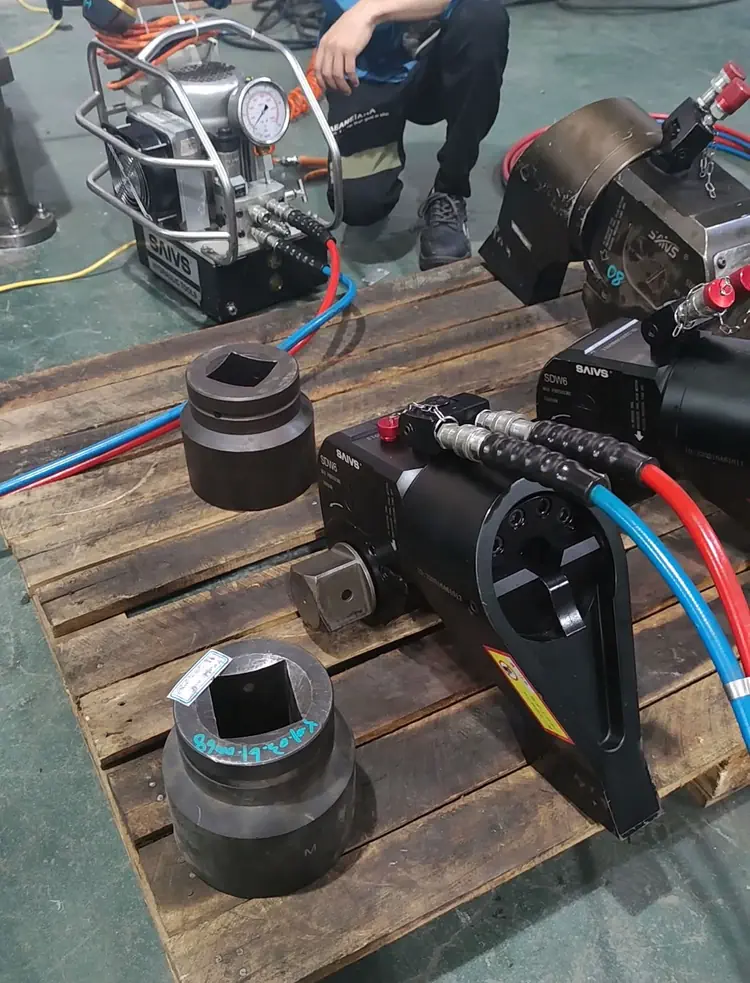

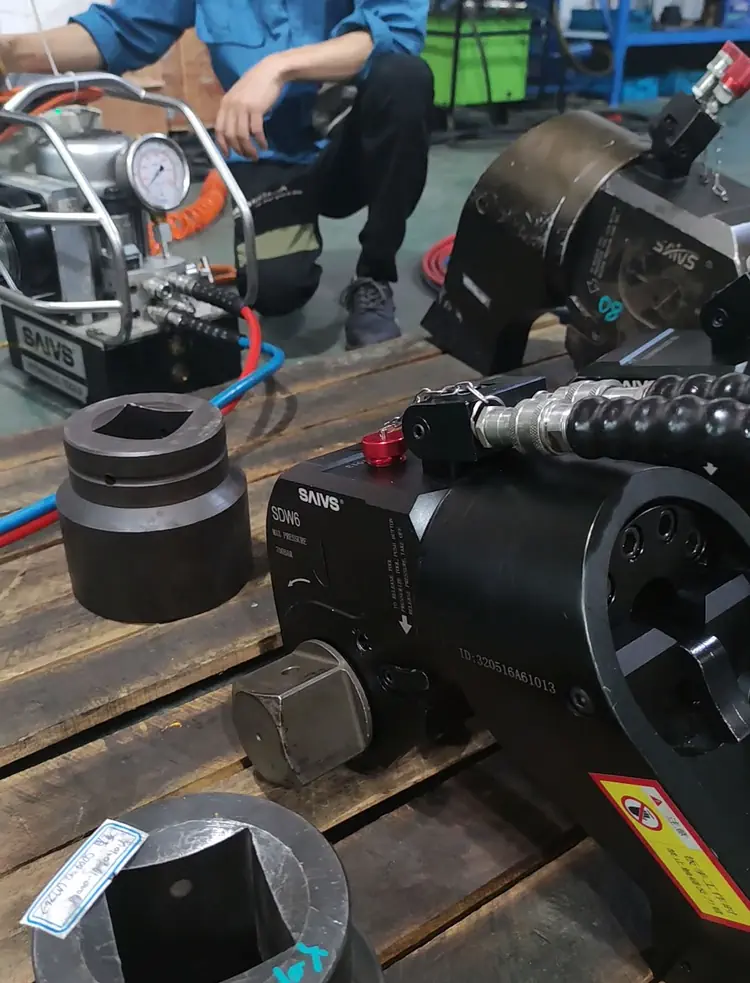

Square Drive hydraulic torque wrench: The Versatile Choice

A Square Drive Hydraulic Torque Wrench is one of the most commonly used tools for industrial torque applications.

It features a square drive mechanism that accommodates a wide range of sockets, making it suitable for various bolt sizes and applications.

Key Benefits:

High torque output with superior accuracy (typically within ±3%)

Versatile and adaptable to different fastener sizes

Durable construction for heavy-duty operations

Low Profile Hydraulic Torque Wrench: Ideal for Tight Spaces

When working in confined areas, a Low Profile Hydraulic Torque Wrench is the preferred choice.

Unlike square drive wrenches, these tools use a direct hex drive, making them perfect for applications with limited clearance.

Key Benefits:

Compact design for easy access in tight spaces

High torque capabilities despite its small size

Reduced risk of fastener damage due to precise load distribution

Why Choose Hydraulic Torque Wrenches for Industrial Fastening?

Hydraulic torque wrenches offer numerous advantages over traditional fastening tools, making them indispensable in industrial settings:

Precision: Achieves exact torque values for consistent fastening

Efficiency: Reduces manual labor and increases productivity

Safety: Minimizes the risk of bolt failures that could lead to accidents

Durability: Engineered to withstand harsh working conditions

How to Select the Right Hydraulic Bolt Torquing Machine

Choosing the right hydraulic torque wrench depends on several factors:

Torque Range: Ensure the tool meets the required torque specifications for your application.

Work Environment: Consider whether you need a square drive or low profile wrench based on space constraints.

Material Compatibility: Choose a wrench that is compatible with the fasteners and materials you are working with.

Reliability and Maintenance: Opt for a trusted brand known for durability and easy servicing.

Conclusion

For procurement professionals looking to invest in hydraulic bolt torquing machines, understanding the differences between Square Drive Hydraulic Torque Wrenches and Low Profile Hydraulic Torque Wrenches is essential.

These tools provide unparalleled precision, safety, and efficiency in industrial torque applications, making them a valuable asset for any operation.

By choosing the right hydraulic torque wrench, businesses can enhance productivity, reduce downtime, and ensure long-lasting equipment integrity.

If you're looking for top-quality hydraulic torque solutions, explore our range of industry-leading torque wrenches designed for precision fastening.