How to Discern the Quality of Hydraulic Cylinder

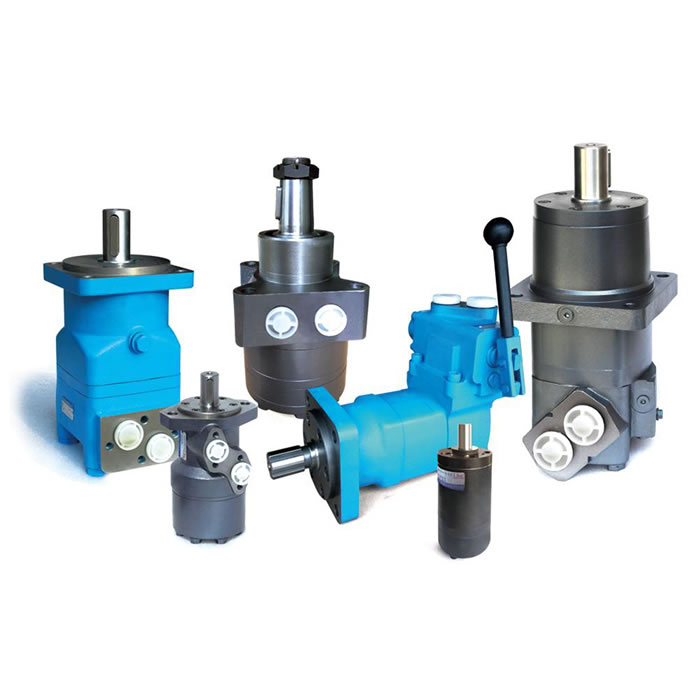

Hydraulic Cylinder is the most widely used actuating element in hydraulic transmission system, which converts oil pressure into mechanical energy for reciprocating linear movement or swing, output force or torque, and then realizes the function of hydraulic cylinder pressure pushing to convert into available energy. It is reliable in operation, simple in structure, smooth in motion and has no clearance between the drives, so it is widely used in various mechanical Hydraulic Systems. With the variety of products available on the market, it is particularly important to choose a cylinder with a high cost performance from a number of cylinder suppliers.

Look at the product parameters. To distinguish the quality of hydraulic cylinder, the performance and parameters of the product are the first consideration. Because the service performance of the hydraulic cylinder can be directly reflected by its parameters, the parameters of the hydraulic cylinder required for different sizes of hydraulic system are also greatly different. Therefore, to distinguish a hydraulic cylinder, it is important to first understand the type and characteristics of the cylinder, and at the same time to look at its parameter information in detail, such as the range of temperature and pressure changes that can be withstood in the cylinder, the size of the piston rod and the efficiency of converting mechanical energy, and the amount of fuel consumed.

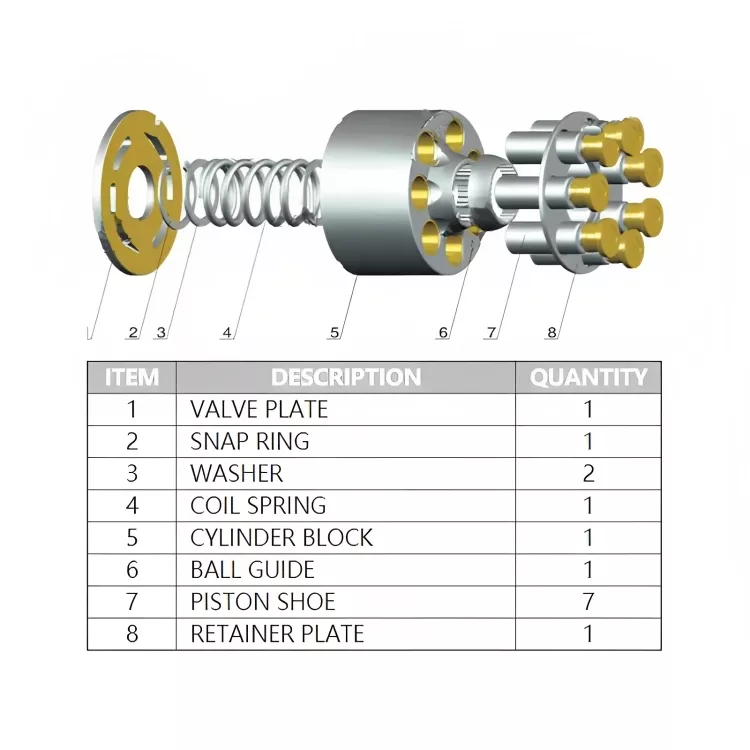

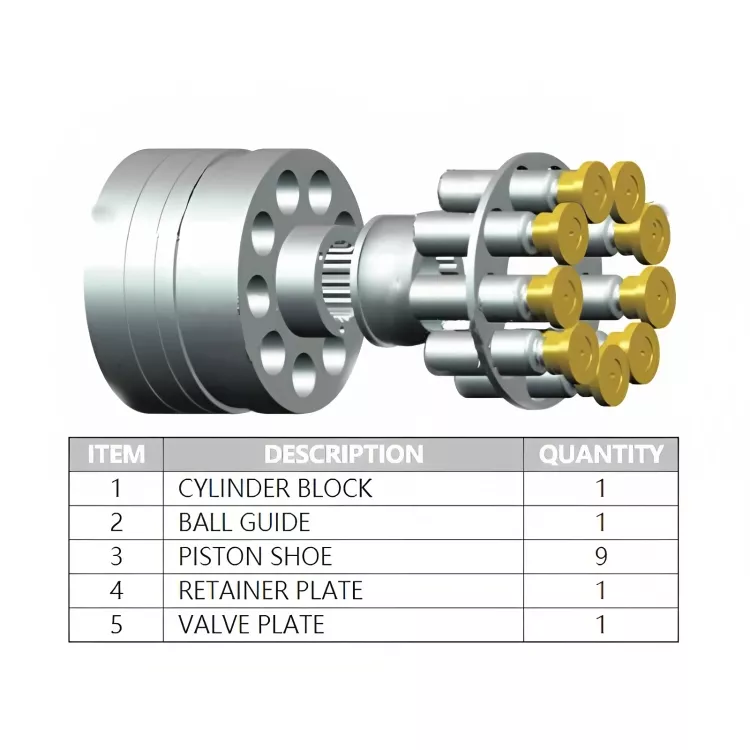

Look at the materials and work pieces. The quality of the hydraulic cylinder has a direct influence on its fabrication material and processing precision. For example, the piston requires excellent stability in the fabrication material due to its long-term contact with the hydraulic oil in the changing environment of pressure and temperature, and no deformation will occur if the temperature changes too much. At the same time, it also depends on the processing conditions of the processed parts. The high-quality processed parts have flat appearance, small burrs and no defects, and the outer coatings are coated with rust-proof and corrosion-resistant materials.

It depends on the size and strength of the manufacturer. To distinguish high-quality Hydraulic Cylinders, we need to know the scale and strength of the manufacturers. Powerful and powerful hydraulic cylinder manufacturers not only have mature production processes and technologies, but also spare no effort in purchasing equipment and have multiple production lines, and have a set of process to strictly control the production process. A large-scale manufacturer is a customer-centered concept, naturally more efforts for customer use and after-sales, the hydraulic cylinders manufactured by this manufacturer are naturally worth expecting.

See product evaluation and word-of-mouth situation. Any product including hydraulic cylinder can be directly reflected by the user's evaluation of the product. The comprehensive service cylinder manufacturer also has stable and reliable performance. Naturally, a large number of loyal old customers will bring them a continuous stream of new customers and receive high praise in the industry.

In conclusion, to distinguish the quality of hydraulic cylinder, it is not only based on the manufacturing material and processing conditions of the cylinder, but also on the strength of the cylinder manufacturer and the external evaluation and word-of-mouth of the product. Reliable cylinders for quality and service not only directly determine the power of the hydraulic system, but also ensure the safe operation of the system.