Debunking Gear Pump Myths: Clarifying Common Misconceptions

Introduction

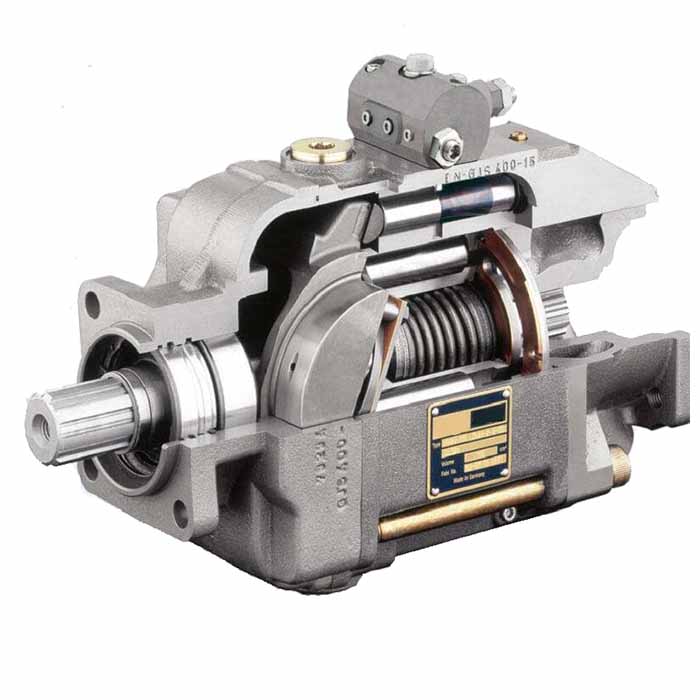

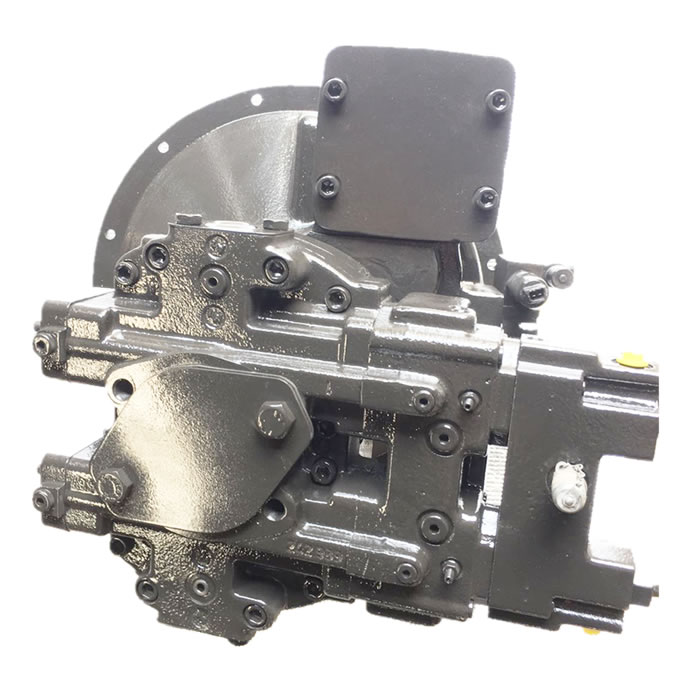

Gear pumps are widely used in various industries due to their ability to handle viscous fluids and generate high-pressure differentials. However, there are several misconceptions surrounding these devices that can lead to confusion or improper application. This article aims to clarify some of the most common misunderstandings related to gear pumps.

1. There is No Such Thing as a “Positive” or “Negative” Gear Pump

One of the most prevalent misconceptions is the categorization of gear pumps as either “positive” or “negative.” In reality, gear pumps do not have such classifications. The term "positive displacement" is sometimes mistakenly shortened, leading to this confusion. A gear pump is a type of positive displacement pump, which means it moves a consistent volume of fluid with each rotation. The misunderstanding likely arises from this terminology, but it is crucial to understand that the gear pump itself cannot be classified as "positive" or "negative."

2. Only Gear Pumps Can Create a Pressure Differential

Another common misconception is that gear pumps are the only type of pumps that can create a pressure differential. While it is true that gear pumps are particularly effective at generating pressure differences, they are not the only pumps capable of this. Other types of pumps, such as Vane Pumps, diaphragm pumps, and piston pumps, can also create significant pressure differentials. The key feature of gear pumps is their efficiency and reliability in generating and maintaining a steady flow under varying pressure conditions, making them highly desirable in specific applications.

3. Direction of Rotation: Gear Pumps Can Rotate Clockwise or Counterclockwise

It is often believed that gear pumps are limited to rotating in only one direction, either clockwise or counterclockwise. However, this is not true. Gear pumps can be designed to rotate in either direction, depending on the application's requirements. The direction of rotation affects the flow direction, but the pump's performance remains consistent regardless of whether it rotates clockwise or counterclockwise. This flexibility makes gear pumps versatile and adaptable to various system designs and requirements.

Conclusion

Understanding the true capabilities and limitations of gear pumps is essential for their effective application in industrial settings. By dispelling these common misconceptions, professionals can make more informed decisions when selecting and using gear pumps in their systems. Gear pumps are reliable and versatile devices, but proper knowledge is key to maximizing their potential and ensuring optimal performance.