8 Mistakes to Avoid When Installing Hydraulic Hoses

Hydraulic hoses are an integral part of many systems, providing a method for transmitting fluid from one component to another.

However, the installation process requires careful consideration and attention to detail to ensure their longevity and functionality.

1.Selecting the Optimal Hydraulic Hose

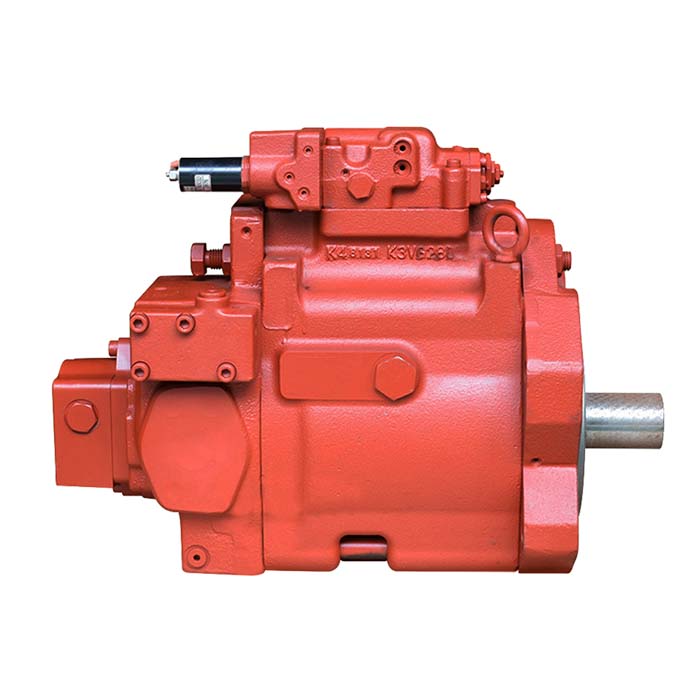

The first step in installing hydraulic hoses is to select the right one for your application.

There are several factors to consider, including the type of fluid, operating temperature, and pressure.

The hose must also be compatible with the Hydraulic System's components, such as pumps and cylinders.

2.Determining the Correct Hose Length

The length of the hydraulic hose is also of utmost importance. It should be long enough to accommodate the system's movements,

but not so long as to create excess slack that could lead to twisting or kinking.

3. Preventing Hose Twist

During installation, it's crucial to avoid twisting the hose. Twisting can cause stress on the hose, leading to premature failure.

Always ensure the hose's natural curvature aligns with the system's movement.

4. Accommodating Movement in the Installation

When installing hydraulic hoses, consider the system's movement. For instance, if the system involves rotating parts,

ensure the hose is installed in a way that accommodates this motion without causing stress or strain on the hose.

5. Maintaining Proper Bend Radius

The bending radius of the hose is another crucial factor. If the bend is too sharp, it can cause kinking, reducing the hose's lifespan.

Always follow the manufacturer's recommended bending radius.

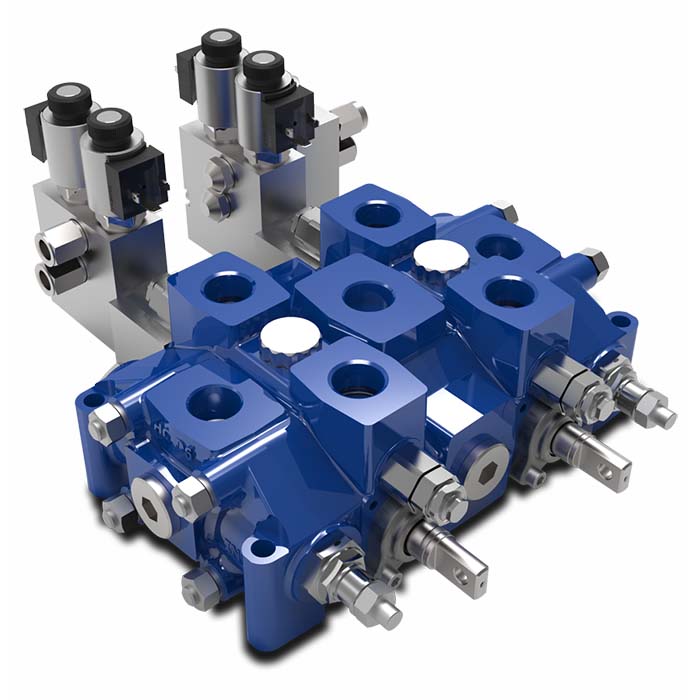

6. Securing Hoses with Clamps

Clamps provide additional support and prevent unnecessary movement of the hoses. They should be used to secure the hose along its length,

particularly at points where it may be subject to vibration or movement.

7. Prioritizing Abrasion Resistance

Hydraulic hoses are subject to wear and tear due to their constant use.

Choose hoses with high wear resistance to ensure they last longer and provide reliable service.

8. Cleaning Hydraulic Hoses

Before installation, it's essential to clean the hydraulic hoses to remove any dirt or contaminants.

These can cause damage to the system and reduce the efficiency of the fluid transmission.

SAIVS Service

Our dedicated team will collaborate with you to design a tailored maintenance strategy that aligns with your specific requirements and goals.

SAIVS is committed to delivering top-notch service and expertise to maximize the efficiency of your vibration isolation systems.

Connect with us today at SAIVS to elevate the performance of your equipment!