8 Common Problems and Solutions of Parker Piston Pump

Parker Parker piston pump is known as a component of hydraulic device. It has many advantages, such as high safety, low noise pollution, simple structure, etc. However, we all know that no matter how long a good product takes, there will be some minor faults. It may also be caused by some unsuitable environmental factors or indirect damage to the pump caused by other factors such as improper operation, which greatly reduces the overall service life of the pump and increases its own production costs. Therefore, based on years of experience and customer feedback, our company has sorted out some problems that may occur in operation and some operation methods. To help you better use the pump to generate Zui's great economic benefits.

The 8 most common problems with Parker piston pumps, combined with years of experience and customer feedback, are as follows:

1. Vibration and noise occur simultaneously

2. Output pressure is abnormal

3. Oil leakage

4. No zero oil displacement at midpoint

5. Hydraulic pump overheating, different from normal phenomena

6. Inadequate or no oil output

7. Fluctuation of Output Flow

8. Lack of pumping flow

8 Common Problems and Solutions of Parker Piston Pump

8 common problems and treatment methods of Parker piston pump:

I. Vibration and noise occur at the same time: there are generally two reasons why both vibration and noise occur at the same time.

1. Noise generated by fluid flow in pipes

Possible causes are:

1) The setting of oil inlet pipeline is too thin

2) The flow capacity of the inlet oil filter is too small or blocked

3) Suck in a lot of air in the intake pipe

4) Excessive fluid immunity

5) Insufficient oil suction due to low oil level

6) Generation of liquids in high pressure pipes, etc.

Treatment method: Check step by step according to the above six problems to find out which part is produced and replace it in time. (Generally, the replacement is required according to the design tank, and the proper selection of oil filter, oil pipe and directional valve is required.)

2. Mechanical Vibration and Noise

Possible causes: 1) Pump shaft and click shaft are not concentric or dead; 2) Damage to bearings, coupling joints, breakage of elastic cushion and loosening of assembly bolts of rotating shaft

Processing method: In daily operation, for pumps with high speed or large transmission energy, periodic and regular checks should be carried out, and the amplitude, frequency and noise of each component should be recorded. If the rotation frequency of the pump is the same as the natural frequency of the Pressure Valve, it will cause resonance, which can be eliminated by changing the pump speed.

8 Common Problems and Solutions of Parker Piston Pump

2. The output pressure appears abnormal phenomenon: the output pressure of the pump is determined by the load and is proportional to the output torque. Generally, the output pressure is too low or too high.

1. Output pressure too low

1) Under the condition of self-priming, if the intake pipeline leaks or the Hydraulic Cylinders, check valves and change-over valves in the system leak greatly, the pressure will not rise up. It is necessary to find out the source of the leakage, tighten or replace the corresponding seals to increase the output pressure.

2) If the relief valve fails or the adjustment pressure is low and the pressure of the system does not go up, then the pressure should be readjusted or the relief valve should be overhauled. If there is a large amount of leakage caused by the deviation between the cylinder block and the valve plate of the hydraulic pump, the cylinder block will break in serious cases. At this time, the mating surface should be ground or the new hydraulic pump should be replaced directly.

2. Output pressure is too high

1) If the loop load rises, the pressure of the pump will rise continuously. This is normal. However, if the load is constant and the pressure of the pump exceeds the pressure required by the load, it is necessary to check the hydraulic components other than the pump, such as the Direction Valve, pressure valve, drive unit and return line. If the pressure is too high, the relief valve should be adjusted accordingly.

3. Oil leakage: In case of oil leakage, the following aspects should be investigated in time

1. Damaged oil seal or defective or scratched shaft

2. Excessive internal leakage will increase the pressure at the oil seal and damage or flush the oil seal out.

3.The drain pipe is too thin and too long, causing oil leakage at the seal.

4.The external oil pipe of the pump is loose, the pipe joint is damaged, the seal gasket is aging or cracked.

5. Loose bolts of variable adjusting mechanism and broken seal

6.Cast iron pump housing with sand holes or poor welding

8 Common Problems and Solutions of Parker Piston Pump

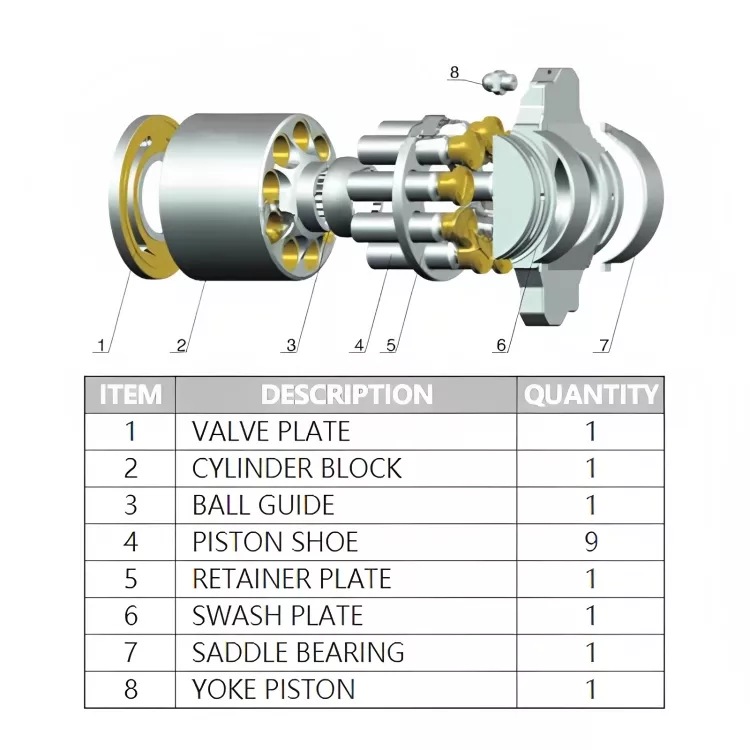

IV. The oil displacement at the middle is not zero

1) When the swash angle of the PARKER Piston Pump is zero, it is called the median, at which time the pump output flow should be zero. But sometimes the midpoint deviates from the midpoint of the adjustment mechanism and there is still flow output at midpoint. The cause is that the position of the controller deviates, becomes loose or has been damaged, requiring re-zero adjustment, tightening or replacement of the controller.

2) Insufficient angle maintenance force of the pump and wear of the inclined trunnion will also cause this phenomenon.

V. Hydraulic pump overheating, different from normal phenomenon

1. Mechanical friction heating: as the moving surface is in a dry friction state, the moving parts are too warm due to friction between each other;

2. Heat generation by liquid friction: high pressure oil leaks into low pressure chamber through various slits, a large amount of hydraulic energy loss is converted into heat energy;

This requires that we correctly select the clearance between moving parts, tank volume and cooler, which can prevent excessive heating of the pump and excessive oil temperature. In addition, blockage of the return filter can cause excessive back pressure of the return oil, which can also cause excessive oil temperature and excessive heat of the pump body. This also reminds everyone to be prepared for protection against burns caused by excessive temperature of the pump body.

VI. There are three reasons for insufficient or no oil output:

1. Insufficient suction volume: the possible causes are excessive resistance on suction line or insufficient oil replenishment, such as excessive pump speed, low liquid level in tank, air leakage in intake line, blocked oil filter, etc.

2. Excessive leakage: the reason is that the pump has too much clearance and poor sealing, such as scratched oil distribution pan by metal debris, iron debris, etc., and oil leakage at the end; The seal surface of check valve in variable mechanism does not fit properly, and the support surface of pump body and oil pan has sand holes or scratches, etc. The damage position of pump can be determined by checking the mixed foreign material in hydraulic oil of pump body.

3.The inclination angle of the tilting plate is too small and the displacement of the pump is too small. It is necessary to adjust the variable piston to increase the inclination angle of the tilting plate.

8 Common Problems and Solutions of Parker Piston Pump

VII. Fluctuation of Output Flow: Factors Affecting Fluctuation are as follows

1. The foreign body enters the variable mechanism and scratches, abrasions and scratches on the control piston cause unstable movement of the control piston.

2. Control piston instability due to insufficient amplifier energy or damaged parts and poor efficiency of control piston dampers with springs

Flow instability is often accompanied by pressure fluctuations. This type of failure generally requires disassembly of the hydraulic pump, replacement of damaged parts, increased damping, increased spring stiffness and control pressure.

8. Check the matching condition of the outlet valve pair of the Parker piston pump, block the lower hole of the outlet valve with your finger and press the outlet valve down slightly with the other finger. When the finger leaves the upper end of the outlet valve, it will automatically spring back to its original position, indicating that the outlet valve pair is well sealed. Otherwise, replace the outlet valve pair of the Parker piston pump.