What should be paid attention to when using hydraulic motors

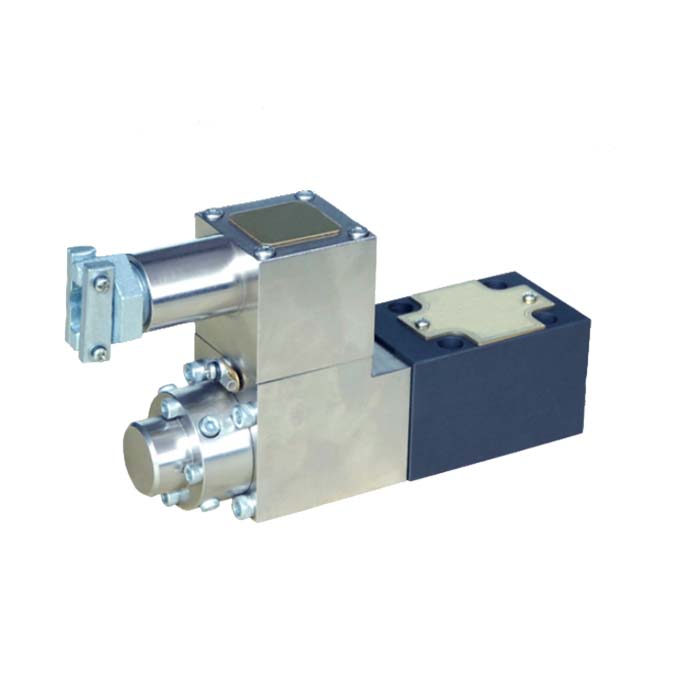

The various types of Hydraulic Motors are widely used in many fields due to their simple structure and low environmental pollution.

As a very efficient hydraulic component, it can quickly input liquid through the hydraulic pump and convert it into a hydraulic motor to drive rotation.

It is precisely because its working principle is relatively complex that many problems need to be paid attention to when using it.

So what should be paid attention to when using Hydraulic Motors?

Note Issue 1: Avoid aging of seals

The key issue to pay attention to when using hydraulic motors is to avoid aging of seals, because if the seals are aged,

it may cause the leakage to increase, and then the friction resistance of the machine will gradually increase. At this time,

the operation of the motor will be unstable, and some hydraulic motors may even have torque fluctuations or creeping.

Therefore, during the operation, it is necessary to understand the condition of the hydraulic motor seals in time and try not to let it run for a long time.

Note the second problem: long-term operation requires cooling treatment

When the hydraulic motor is running for a long time, it should be noted that the motor is constantly running and causing high temperatures,

especially when there is too much friction between some parts or the time is too long, which will cause high temperatures.

Once the high temperature appears, the gap inside the machine will increase, and the pressure in the shell will increase over time.

At this time, the volumetric efficiency will be reduced. Therefore, when the hydraulic motor is running for a long time,

it must be properly cooled to ensure the normal operation of the equipment.

The two key points that need to be paid attention to in the operation of high-stability hydraulic motors are the aging of the seals and the temperature.

In particular, the hydraulic motor is prone to some problems during long-term operation.

At this time, the equipment must be shut down in time and the fault must be checked and eliminated,

so as to better ensure the stability of the equipment in the later operation.