hydraulic pump maintenance

Hydraulic Pump Maintenance

The common problem in the hydraulic pump maintenance is that the pressure of Hydraulic System is abnormal, and the pressure can not go up or down.

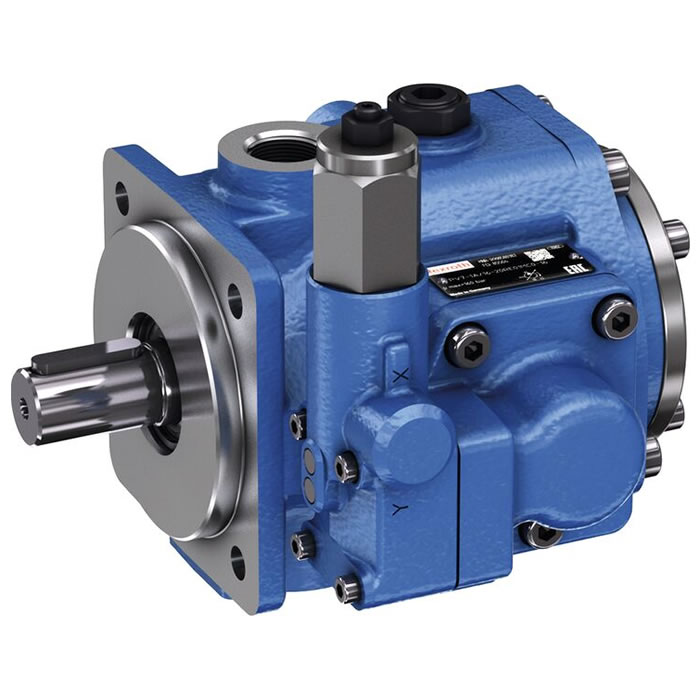

The hydraulic pump is an important component of the hydraulic system. It is the power component of the hydraulic system. It is driven by the electric motor. It draws the oil pump from the hydraulic oil tank, forms the pressure, and sends it to the actual action component. The hydraulic pump is classified into gear pump, plunger pump, Vane Pump and screw pump according to the structure.

Pressure is one of the two basic parameters of the hydraulic system, which determines the working function of the hydraulic system on a very large basis. This fault appears as follows: when adjusting the pressure of the hydraulic system, the pressure of the adjustment failure system can not rise, the pressure is insufficient, or the pressure rises and then falls down, resulting in instability, pressure vibration and other phenomena.

1. Causes of abnormal pressure

The hydraulic pump forms no flow conveying or the conveying flow is not enough, the pressure regulating valve such as overflow valve fails, the unloading valve is stuck in the unloading position, the total unloading pressure of the system does not go up, the internal and external leakage of the system, the valve mounting plate has the position where the pressure oil channel and the return oil channel cross connect, the valve core of the reversing valve does not reverse and move in place, forming the channeling cavity between the pressure oil cavity and the return oil cavity, and the Hydraulic Cylinder The lock nut connecting the piston and the piston rod is loose, and the piston runs out of the piston rod, so that the two cavities of the hydraulic cylinder communicate with each other.

2. Impact of pressure disorder

This will lead to the implementation of component behavior or behavior, but the load will stop running, unable to do work, the hydraulic system can not complete the accurate work cycle. Some valves relying on pressure control can not work, such as hydraulic reversing valve, hydraulic control single valve, plug-in valve, Pressure Relay, etc., thus forming the hydraulic system can not work normally, the speed of the implementing elements can not reach the load flow rate to reduce the activity speed, and the safety failure occurs due to the pressure adjustment out of control.

3. Ways to avoid abnormal pressure

Change the motor wiring, correct the rotation target of the hydraulic pump, change the motor matching the power, correct the inlet and outlet target of the hydraulic pump, which requires more attention to the non reversible pump. Appropriate size of the suction pipe of the crude pump, strengthen the sealing at the joint of the suction pipe, wash the oil filter, eliminate the failure of the target valve, find out the detailed location of the internal and external leakage, and regularly inspect the oil cylinder.