What is Electrohydraulic Servo Valve?

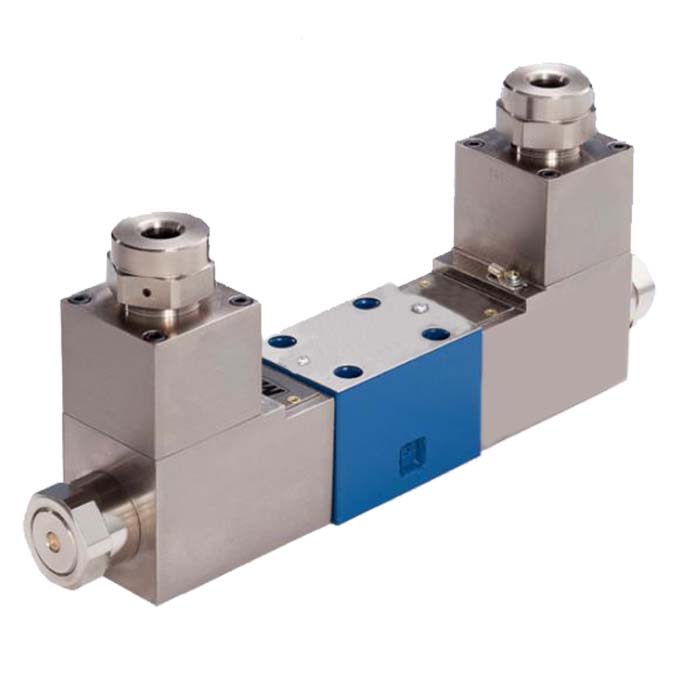

Electro-hydraulic servo valve is a key component in electro-hydraulic servo control, it is a kind of hydraulic control valve which accepts the analog output and adjusts the flow and pressure. Electro-hydraulic servo valve has the advantages of fast dynamic response, high control precision and long service life. It has been widely used in electro-hydraulic servo control system in the fields of aviation, aerospace, ship, metallurgy and chemical industry.

The hydraulic servo valve is the core component of the hydraulic servo control system, so the hydraulic control system books will contain the contents of the electrohydraulic servo valve.

1. Development Process

The birth of electro-hydraulic servo valve technology is the result of the development of hydraulic control technology and hydraulic control system. On the eve of World War II, with the development of industrial needs, hydraulic control technology has developed by leaps and bounds, many early control valve principles and patents are the products of this era. Such as: Askania Regulator and Askania-Werke invented and applied for the principle of the principle of jet valve. Similarly Foxboro invented the patent of the nozzle baffle valve principle. German Siemens has invented a dual-input valve with a permanent magnet motor and a receiver and electrical input, and is groundbreaking in the aerospace field.

At the end of World War II, the servo valve is a single-stage open-loop control valve that directly drives the spool movement with a solenoid. However, with the control theory of the maturity and the needs of military applications, servo valve development and development has made great achievements. In 1946, the British Tinsiey won the two-level servo valve patent; Raytheon and Bell invented a feedback with two-stage servo valve; MIT torque motor instead of the solenoid to make the motor power consumption is smaller and better linearity. In 1950, W.C.Mogog first invented a single-nozzle two-stage servo valve. From 1953 to 1955, THCarson invented a mechanical feedback two-stage servo valve; WCMoog invented a two-nozzle two-stage servo valve; Wolpin invented the dry torque motor, eliminating the original immersed in the oil within the torque motor by the oil Liquid pollution brought about by the reliability of the problem. In 1957 R.Atchley developed the two-stage jet tube servo valve using the Askania jet tube principle. And in 1959 developed a three-stage electric feedback servo valve. At that time the servo valve is mainly used in the military field, with the advent of the space age, servo valve has been widely used in the aerospace field, and developed a high reliability of the redundant servo valve and other cutting-edge products.

At the same time, with the servo valve industry applications continue to expand, some manufacturers developed specifically used in industrial applications, industrial servo valve. Subsequently, more and more for the industrial use of the development of the servo valve appeared. They have the following characteristics: a larger volume to facilitate the manufacture; valve body with aluminum; independent first level to facilitate the adjustment and maintenance; mainly used in the 14MPa below the low-pressure occasions; try to form a series of standardized products. With the widespread use of servo valves in industrial applications, companies have introduced their own suitable for industrial applications with the proportion of the valve. It is characterized by low cost, although the control accuracy is not comparable to the servo valve, but through advanced control technology and advanced electronic devices to make up for its lack of performance and efficiency close to the servo valve.. Bosch developed its iconic jet tube pilot and electro-feedback flat-plate servo valve.. Vickers has developed a pressure compensated KG type proportional valve. Rexroth, Bosch and others developed a proportional valve that controls the movement of the spool in both directions with two coils.

2.Market Outlook

Production of servo valve manufacturers are: the United Kingdom Dowty, the United States Team, the United States Parker, Eaton Vickers, Germany Bosch, Rexroth and so on.

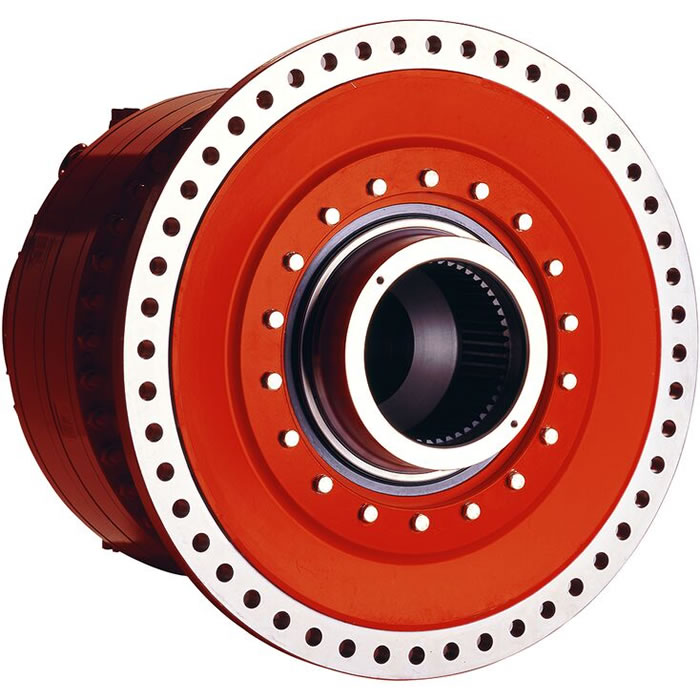

Electro-hydraulic servo valve generally according to the torque motor type is divided into moving coil and permanent magnet type two. Most of the traditional servo valve using permanent magnet torque motor, such servo valve can be divided into nozzle baffle and jet two categories. The original production of jet tube servo valve manufacturers Abex United States has also been Parker acquired. However, due to the jet tube servo valve with good anti-pollution performance, high reliability, high resolution and so on. Some manufacturers are also developing or have launched their own jet tube products.

Hydraulic Servo valve products are mainly used in aviation, aerospace, ships and other fields. At the same time as the production units of their own war, the lack of cooperation, the power of dispersion, is not conducive to the further development of servo valve, can not form a strong competitive edge with foreign products.

3.Development Trend

At present, the development trend of the new electro-hydraulic servo valve technology is mainly embodied in the design of new structure, the use of new materials and the combination of electronic, digital technology and hydraulic technology. The development of electro-hydraulic servo valve technology has greatly promoted the development of hydraulic control technology.

4.Design of New Structure

In the 1990s, the development of direct-acting electro-hydraulic servo valve was a great achievement. Parker has developed Voice Coil Drive technology (VCD), and DFplus control valves developed on this basis. The so-called voice coil drive technology, is similar to the speaker of a drive device, the basic structure is set in a fixed cylindrical permanent magnet on the mobile coil, when the signal current input coil, the role of the electromagnetic effect, the coil produced And the signal current corresponding to the axial force, and drive directly connected with the coil of the spool movement, driving force is very large. The coil built-in displacement feedback sensor, therefore, using VCD-driven DFplus valve is essentially closed-loop control, linearity is quite good. The full support of the DFplus valve is the mating surface between the spool and the valve body, which greatly reduces the effect of friction on the quality of the control. Integrated with the technical characteristics of the above, with the built-in digital control module, the DFplus valve control performance, especially in the frequency response is superior, up to 400Hz. From the development trend, the new direct-acting electro-hydraulic servo valve in some industries have replaced the traditional servo valve, especially the nozzle baffle servo valve trend, but its biggest problem is the large size, heavy weight, only for the right The site requires a lower industrial servo control. Such as to reduce its weight, reduce its size, in the aviation, aerospace and other military industry also has great potential for development.

In addition, in recent years, the new type of servo valve drive in addition to the direct drive of the torque motor, but also the emergence of the use of stepper motor, servo motor, new electromagnet and other drive structure and light - liquid direct conversion structure of the servo valve. The application of these new technologies not only improve the performance of the servo valve, but also for the development of servo valve ideas, electro-hydraulic servo valve technology into a new vitality.

5.The use of New Materials

The current use in the field of electro-hydraulic servo valve development of new materials, mainly based on piezoelectric components, giant magnetostrictive materials and shape memory alloys based on the converter research and development. They each have their own excellent characteristics.

5.1 Piezoelectric Components

Piezoelectric element is characterized by "piezoelectric effect": in a certain electric field under the action will produce changes in the size, in a certain range, deformation and electric field strength is proportional. Piezoelectric components of the main materials for the piezoelectric ceramic (PZT), electrostrictive materials (PMN) and so on. The typical piezoelectric ceramic materials are Japan's TOKIN company's stacked piezoelectric telescopic ceramics. PZT direct acting servo valve principle is: at both ends of the spool through the ball were connected with two multi-layer piezoelectric components. Through the piezoelectric effect of the piezoelectric material to produce telescopic drive spool movement. To achieve electrical - mechanical conversion. PMN nozzle baffle servo valve is set in the nozzle with a piezoelectric stack fixed connection of the baffle, by the piezoelectric stack of the extension, shrinkage between the baffle and the gap between the nozzle increase and decrease, so that both ends of the spool The pressure differential drives the spool to move. At present, the development of piezoelectric electric-mechanical converters is relatively mature and has been widely used. It has the characteristics of fast frequency response, servo valve bandwidth can even reach thousands of hertz, but there are hysteresis, easy drift and other shortcomings, restricting the piezoelectric components in electrohydraulic servo valve on the further application.

5.2 Giant Magnetostrictive Material

The giant magnetostrictive material (GMM) produces much larger length or volume changes under the action of a magnetic field than conventional magnetostrictive materials. The GMM converter is developed by using the GMM converter. The GMM converter is connected with the spool. By controlling the current of the drive coil, the GMM is driven and extended to drive the displacement of the spool to control the servo valve output flow. Compared with the traditional servo valve, the valve not only has the characteristics of high frequency response, but also has the advantages of high precision and compact structure. From the current situation, GMM materials and piezoelectric materials and traditional magnetostrictive materials compared with a large strain, high energy density, fast response, the output force and so on. Countries around the world GMM electric - mechanical converter and related technology research is very important, the future need to address the GMM thermal deformation, magnetocrystalline anisotropy, material corrosion and manufacturing processes, parameter matching and other aspects of the problem in order to facilitate high-tech The field is widely used.

5.3 Shape Memory Slloy

Shape memory alloy (SMA) is characterized by a shape memory effect. After it is shaped at a high temperature, it is cooled to a low temperature state, and an external force is applied thereto. General metal in its elastic deformation will occur after the permanent deformation, and SMA is heated to a certain temperature above it will restore its original high temperature shape. The servo valve developed with its characteristic is a SMA actuator which is wound at both ends of the spool by a shape memory alloy to drive the SMA actuator by heating and cooling so that the shape memory alloy at both ends of the spool is elongated or Shrink, drive spool action to move, while adding position feedback to improve the servo valve control performance. From the case of the valve, SMA deformation, but its response speed is slow, and the deformation is not continuous, but also limits its scope of application.

Compared with the traditional servo valve, the use of new materials, electric-mechanical converter developed servo valve, generally with high frequency response, high precision, compact structure. Electro-hydraulic servo valve is widely used in electro-hydraulic position, speed, acceleration, force servo system, and servo vibration generator. It has the advantages of small size, compact structure, high power amplification coefficient, high control precision, good linearity, small dead zone, high sensitivity, good dynamic performance and fast response. The current hydraulic servo control technology has been able to automatically control technology, hydraulic technology and microelectronics organic combination to form a new generation of servo valve products. With the electronic equipment, control strategies, software and materials and other aspects of the development and progress, electro-hydraulic control technology and servo valve products will be in the machine, electricity, liquid integration has made great progress.