What factors should be considered when selecting a Parker piston pump?

What factors should be considered when selecting a Parker piston pump?

Or, what do we need to notice when choosing a Parker piston pump?

Colan Hydraulics to tell you:

I. Selection of Reliability Life and Energy Saving of Parker Piston Pump

1. Use Pressure and Flow of Hydraulic Drive System

Taking Buyi gear oil pump as an example, it can be divided into high, medium and low pressure in 3rd gear. Low pressure < 2.5MPa, medium pressure 8-16MPa and high pressure 20-31MPa. At the same time, the displacement of gear pump is determined according to the flow required by the system and the speed of motor. If the system uses piston pump, the pressure of the system should be 70%~80% of the discharge pressure of the pump, which is economical and guarantees sufficient service life of the pump. However, the hydraulic diaphragm pump is not used as far as possible for Pike piston pump. Due to the particularity of the Hydraulic System, the built-in safety valve of the hydraulic diaphragm pump easily jumps off, which causes the system to not work properly.

2. System Requirements for Noise and Flow Ripple Rate

The noise of external rodent gear pump is large, the flow fluctuation rate is large, the noise of internal rodent gear pump is small and the flow fluctuation rate is small. The noise of Vane Pump, screw pump and piston pump is lower, and the noise of double-acting vane pump is lower than that of single-acting vane pump. As far as flow fluctuation rate is concerned, double-acting vane pump has the smallest flow fluctuation rate, followed by piston pump, while single-acting vane pump and piston pump have the medium flow fluctuation rate.

3. Work Reliability, Service Life and Price

Dual-acting vane pump has a long life, while single-acting vane pump, piston pump, gear pump and screw pump have a short life. Compared with gear pump and vane pump, piston pump is more expensive in price, while screw pump is the most expensive, but screw pump is the most stable in reliability, followed by piston pump, gear pump and vane pump.

4. Factors of pollution

Low pressure gear pump has low pollution sensitivity, which allows the system to select oil filter with low filtering precision. In contrast, high-pressure gear pumps are more sensitive to contamination. Screw pump, piston pump and vane pump are sensitive to oil contamination, so filtration should be strengthened.

5. Energy-saving angle

In order to save energy and reduce power consumption, variable vane pump with proportional pressure and flow control should be selected. Using double pump, triple pump and multiple pump is also a scheme for energy saving.

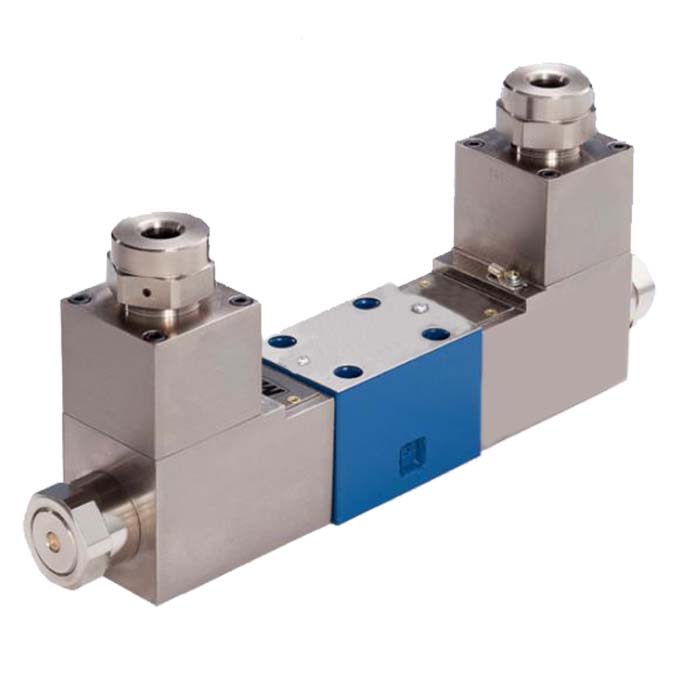

Parker PVP Series Piston Pumps

II. Selection of Performance Flow Pressure of Parker Piston Pump

The main principle of selecting Parker piston pump is to meet the operating conditions of the system, and based on this, the output, working pressure and configuration of the pump are determined.

1. The flow rate of the rated flow pump should satisfy the highest speed requirement of the actuating element, so the output flow QP of the pump should be determined according to the maximum flow and leakage required by the system.

2. The working pressure of the rated pressure pump should be determined according to the maximum working pressure of the Hydraulic Cylinder. The rated pressure and maximum pressure of the pump are indicated in the product sample of Parker Piston Pump. After calculating the Pp, the pump should be selected according to the rated pressure, so that the rated pressure of the selected pump is equal to or higher than the calculated value. In use, only in the case of short overloads or in the scope of special instructions in the product manual, high pressure selection of the Parker piston pump is permitted.

3. Select the specific structure type of the Parker piston pump. When the output flow and working pressure of the Parker piston pump are determined, the specific structure type of the pump can be selected. Compare the determined P and QP values with the rated pressure and flow rate on the name plate of the Parker piston pump to be selected so that the values on the name plate are equal to or slightly greater than the P and QP values (be careful not to be too large).

4. Determine the speed of Parker piston pump When the type and specification of Parker piston pump are determined, the speed of Parker piston pump should be selected according to the speed specified in the product sample.