What are the common structural forms of hydraulic motors?

What are the common structural forms of Hydraulic Motors?

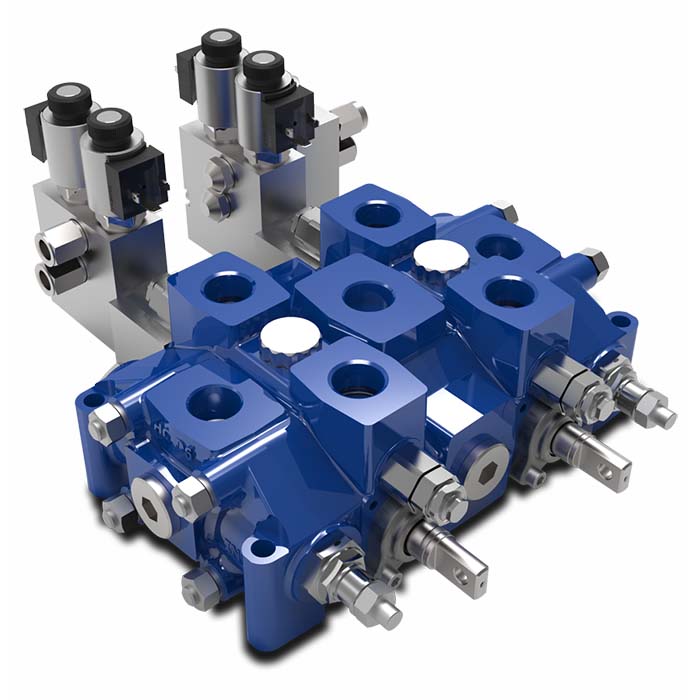

Reliable performance Hydraulic Motors can provide higher starting and running torque and

reduce mutual friction to improve the efficiency of their application, especially at low speeds.

They can also have very stable output, and meet the actual requirements of various speeds and torques

by turning the rollers of the output and input flows. So what are the common structural forms of hydraulic motors?

Let's elaborate on this issue in detail.

Common structural form 1: blade type

There are many structural forms of hydraulic motors, among which the most common one is the blade type.

Compared with other structural forms, the output torque of the blade type has a great relationship with

the displacement and the pressure between the inlet and outlet ports, and the overall speed is determined by

the size of the flow rate. Since the motor needs to rotate forward and backward during operation,

the blades need to be placed radially. In addition, the blade type hydraulic motor structure has a relatively

small moment of inertia, which is very suitable for some production environments with high conversion frequencies.

Because of its small torque, it is more suitable for some occasions with high sensitivity requirements.

Common structural form 2: radial piston type

In the actual working process, the radial piston hydraulic motor often enters the bottom of the plunger in the cylinder through the pressure oil.

When the plunger extends outward, it will tightly press against the inner side of the stator and maintain a corresponding distance from the cylinder.

When the plunger contacts the stator, a reaction force will appear to help it run quickly.

This type of structural form of hydraulic motor is mainly divided into two different forces when it works, one is the pressure of the oil,

and the other is the pressure generated by the contact of the cylinder. Compared with other structural forms,

this type of hydraulic motor has a higher output torque and faster speed.

In short, there are many structural forms of hydraulic motors with good service quality,

and different structural forms are applicable to completely different scenarios. In actual selection,

the characteristics of the structural form can be mainly considered.

Since the different structural forms of hydraulic motors are applicable to completely different scenarios,

the characteristics of these structures can be combined for comprehensive screening when selecting.