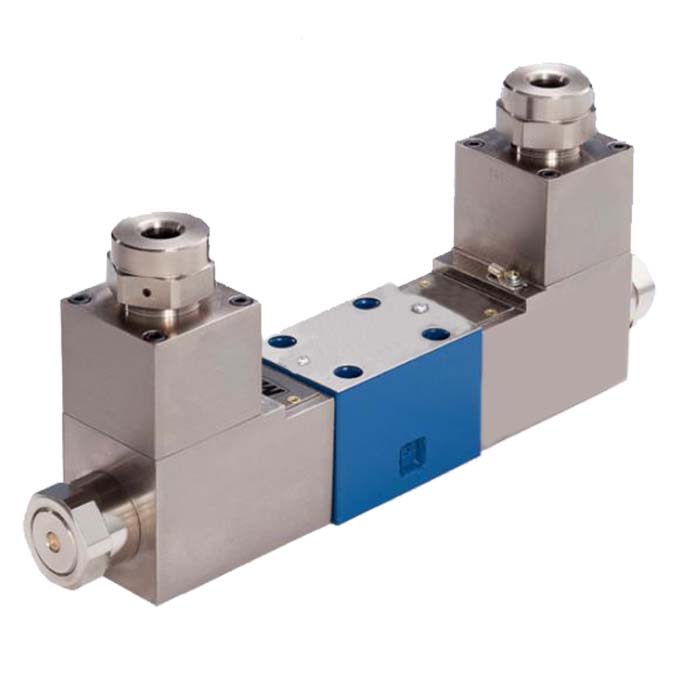

Types of Flow Control Valves

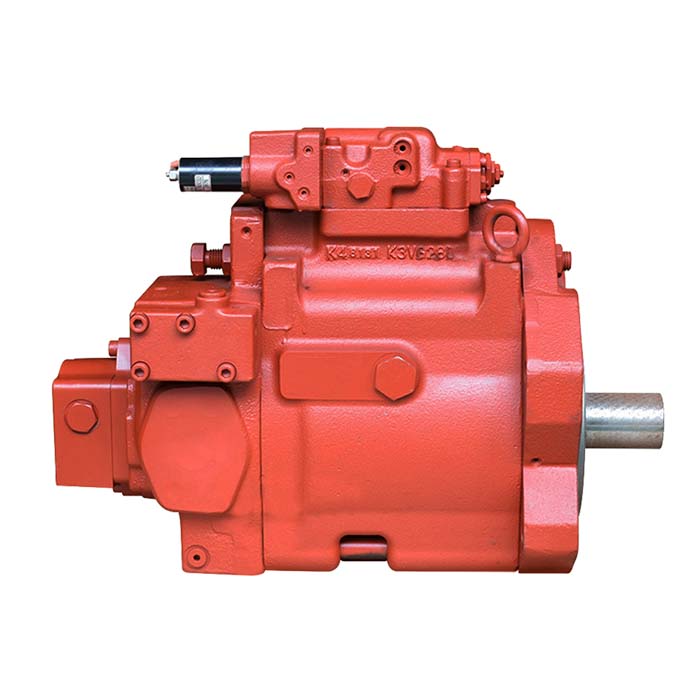

Hydraulic valves have many functions on a Hydraulic System. Valves simplify the operations of every complex hydraulic system by controlling the direction, flow, and pressure of fluids. Here, we can discuss more on the hydraulic flow control valve types, an important valve that helps to regulate the flow of fluids through the system.

Most of the constant flow circuits use hydraulic flow control valves. Regulating the speed of actuators, regulating the power to subcircuits, dividing and regulating the pump flow, etc.. are the functions of flow control valves. These valves will provide a variable restriction to the flow path. The flow through the valve can be controlled by adjusting the area of the valve opening. To increase the fluid flow, the area of valve opening increases and to decrease the fluid flow, the area of valve opening is reduced.

The flow control valves don’t obstruct the fluid flow as a result of contamination. This anti-clogging property is an important feature of flow control valves. Reduced fluid consumption, low cost, reliability and improved performance are the main advantages of the flow control valve. Regulating the speed of cutting tools, spindle, surface grinders, etc.. are some applications of flow control valves.

There are different types of flow control valves available in the market. Gate valve, globe valve, pinch valves, diaphragm valves, and check valves are some major categories. We can discuss more details related to these types in this section.

Gate Valve: Gate valves are compatible with a wide range of fluids and are suitable for high-pressure high-temperature applications. These valves are used for on/off, non-throttling service requiring a straight-line flow of fluid with minimum Gate valves restriction. But, these valves are not suitable for slurries and viscous fluid. Vibration and slow response characteristics are the drawbacks of gate valves

Globe Valve: Globe valves are linear motion valves to stop, start and regulate flow. These valves are used for on/off and throttling applications. Globe valve is a general purpose flow control valve used for high-temperature applications. These valves are comparatively faster and reliable with a limitation of seat disc wear in partial open conditions.

Pinch Valve: Pinch valves are low-cost flow control valve suited for slurries or liquids containing significant amounts of suspended solids. It uses a pinching effect to control the fluid flow. These valves provide 100% tight shut-offs and are used in food, chemical, wastewater, and beverage industries.

Diaphragm Valve: Diaphragm valves are an important category of flow control valve used for throttling services. These valves are suitable for applications using corrosive liquids at low temp and pressure. Diaphragm valves have leak-proof seals that ensure tight shut-offs. Also, these valves are extremely clean and easy to maintain.

Check Valve: Check valve are unidirectional valves used in pumps, aircraft hydraulic system, irrigation sprinklers, etc. These valves contain two ports, to enter fluid and to discharge fluids. By preventing the backflow of fluids, these valves will protect the pumps and compressors in the system. Maintaining pressure and serving as a backup system are the important advantages of check valves. These valves are not suitable with pulsating systems.

Text Source: WHYPS