The difference between hydraulic extrusion machine, hydraulic motor and hydraulic pump

The difference between hydraulic extrusion machine, Hydraulic Motor and hydraulic pump

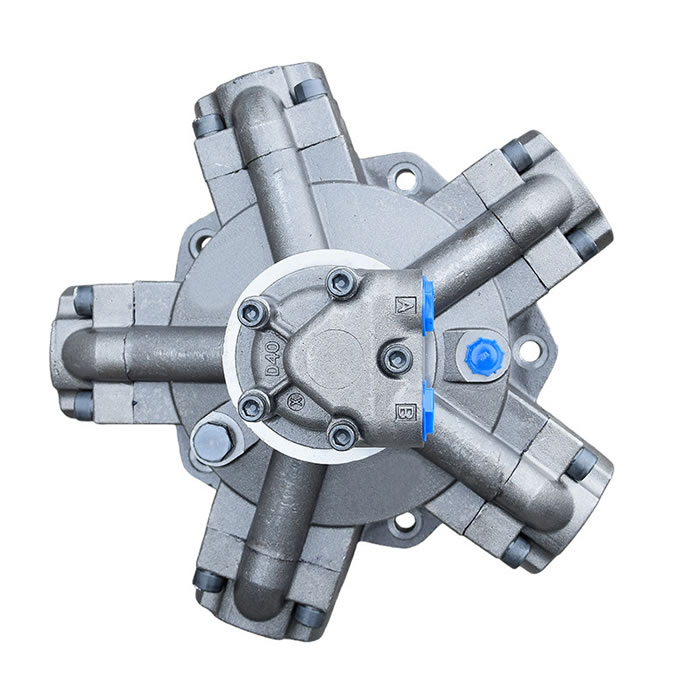

What exactly are the Hydraulic Motors and Hydraulic pumps used in the hydraulic punching machine, and what are their generalizations? Can you understand it literally, then some of the following knowledge is about the difference between hydraulic motors and hydraulic pumps in hydraulic punching machines.

1) In principle, hydraulic motors and hydraulic pumps are reversible. If driven by a motor, the output is hydraulic energy (pressure and flow), which is a hydraulic pump; if pressure oil is input, the output is mechanical energy (torque and speed), it becomes a hydraulic motor.

2) From a structural point of view, the two are similar.

3) From the point of view of working principle, both of them use the change of sealed working volume to absorb and discharge oil. For hydraulic pumps, oil is sucked when the working volume increases, and high-pressure oil is discharged when the working volume decreases. For hydraulic motors, high-pressure oil enters when the working volume increases, and low-pressure oil is discharged when the working volume decreases.

Differences between hydraulic motors and hydraulic pumps:

1) The hydraulic pump is a conversion device that converts the mechanical energy of the motor in the hydraulic punching machine into hydraulic energy, and outputs flow and pressure. It is hoped that the volumetric efficiency is high; the hydraulic motor is a device that converts the pressure energy of the liquid into mechanical energy, and the output torque and rotational speed, it is hoped that the mechanical efficiency is high. Therefore, the hydraulic pump is an energy device, and the hydraulic motor is an actuator.

2) The steering of the output shaft of the hydraulic motor must be able to rotate forward and reverse, so its structure is symmetrical; while some hydraulic pumps (such as gear pumps, Vane Pumps, etc.) have clear regulations on the steering, which can only rotate in one direction and cannot Change the direction of rotation at will.

3) In addition to the oil inlet and outlet, the hydraulic motor also has a separate oil leakage port; the hydraulic pump generally only has the oil inlet and outlet (except for the axial piston pump), and the leakage oil in it communicates with the oil inlet.

4) The volumetric efficiency of the hydraulic motor is lower than that of the hydraulic pump;

Generally, the working speed of the hydraulic pump is relatively high, while the output speed of the hydraulic motor is relatively low. In addition, the oil suction port of the gear pump is large and the oil discharge port is small, while the suction port and the oil discharge port of the gear hydraulic motor are the same size;

The gear motor has more teeth than the gear pump;

The vanes of the vane pump must be installed obliquely, while the vanes of the vane motor should be installed radially;

The vane of the vane motor is pressed against the surface of the stator by the swallow spring at the root, while the vane of the vane pump is pressed against the surface of the stator by the pressure oil at the root and centrifugal force.

The points above mentioned the similarities and differences between hydraulic motors and hydraulic pumps, so hydraulic motors can be used instead of hydraulic pumps in some cases, but in some cases it cannot be done.