Rexroth Repair and Daily Maintenance Principles

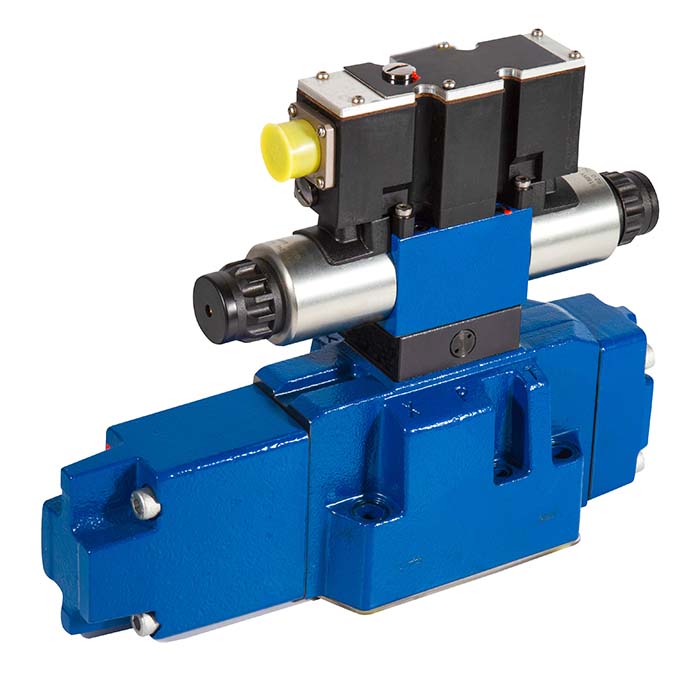

Rexroth Principle: It is a combination of direct and pilot-operated principle. When there is no pressure difference between inlet and outlet, when energized, the solenoid force directly lifts the pilot small valve and the main valve closing parts upward in turn, and the valve opens. When the startup pressure difference between inlet and outlet is reached, after energizing, the solenoid force pilotes the small valve, the pressure in the lower chamber of the main valve rises and the pressure in the upper chamber decreases, thus the main valve is pushed upward by using the pressure difference; In the event of power failure, the pilot valve uses spring force or medium pressure to push the closing member downward to close the valve.

Features: It can also be operated at zero differential pressure or under vacuum and high pressure, but with high power, it is required to be installed horizontally.

Direct Solenoid Valve:

Principle: When energized, the solenoid coil generates electromagnetic force to lift the closing part from the valve seat and open the valve; When the power is cut off, the electromagnetic force disappears, the spring presses the closing piece against the valve seat and the valve closes.

Features: It can work normally under vacuum, negative pressure and zero pressure, but its diameter generally does not exceed 25mm.

Pilot solenoid valve:

Principle: When energized, the electromagnetic force opens the pilot hole, the pressure in the upper chamber drops rapidly, resulting in a low and high differential pressure around the closing part. The fluid pressure pushes the closing part upwards and the valve opens. When the power is cut off, the spring force closes the pilot hole, and the inlet pressure quickly creates a lower and higher differential pressure around the closing part through the bypass hole. The fluid pressure pushes the closing part down and closes the valve.