Repair procedure for hydraulic motors

Hydraulic Motor repair:

1. Repair of stator and rotor The repair of rotor is deburring, grinding and reusing after slight burring or wear. Severe wear can be repaired by brush plating outer circle, or tooth profile can be machined by wire cutting and slow-moving wire after measurement, and then replaced by new parts after heat treatment.

The stator is repaired by deburring, grinding and reusing if it is slightly brushed or worn by needle-tooth inserts. In case of severe wear, the outer diameter can be enlarged to process new pin teeth for replacement. If not, it can be machined and replaced as the rotor.

2. Repair of oil distribution shaft or pan

The repair of oil distribution shaft is to deburr, grind and reuse slightly brushed or worn; Severe cases may be repaired or reworked by brush plating.

Oil distribution pan is repaired as surface A wear and pull, slightly grinded and reused; Severe cases can be reused after flat grinding and surface nitriding.

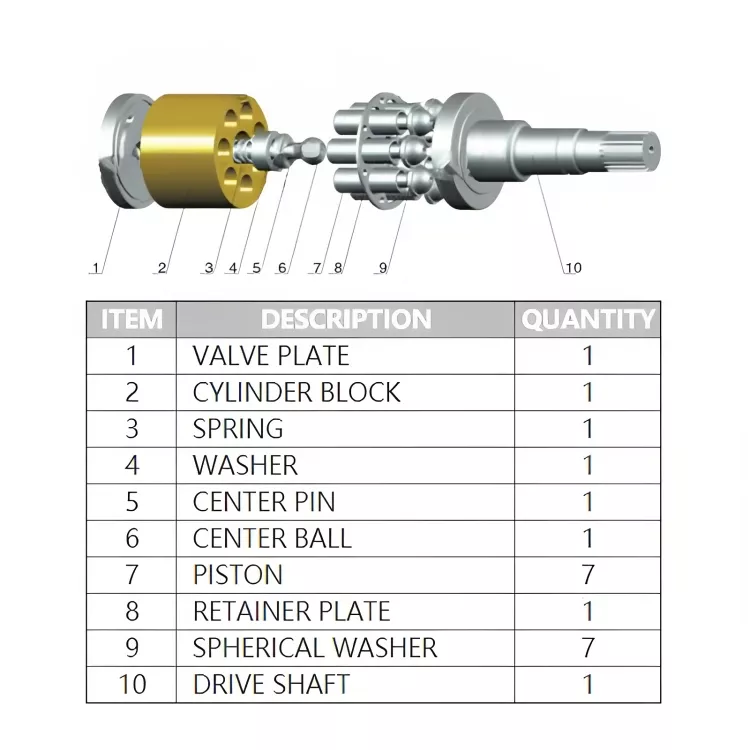

valve plate

Grinding or refinishing

Disassembly and assembly method:

1. Clamp motor in vice

2. Remove end cap

3. Remove motor core

4. Remove drive shaft

5. The shell turns and clamps on the upper ring of the vice

6. Remove relevant parts of shaft seal

7. Check the damage of shaft seal related parts h, Step 8. Prepare the tool for removing oil seal.

8. Remove shaft seal and dust-proof sealing ring with special tool i, step 10, take plug

9. Pull out or insert output shaft

10. Install oil seal, dust ring and other sealing rings into flange cover with inner and outer sleeve tools

11. Output Shaft Insertion Housing

12. Install flange cover

13. Clamp the fitted parts on the vice

14. Marking into motor core

15. Installing rear cover