Proper Flange Bolting Techniques Using Hydraulic Torque Wrenches

Proper Flange Bolting Techniques Using Hydraulic Torque Wrenches

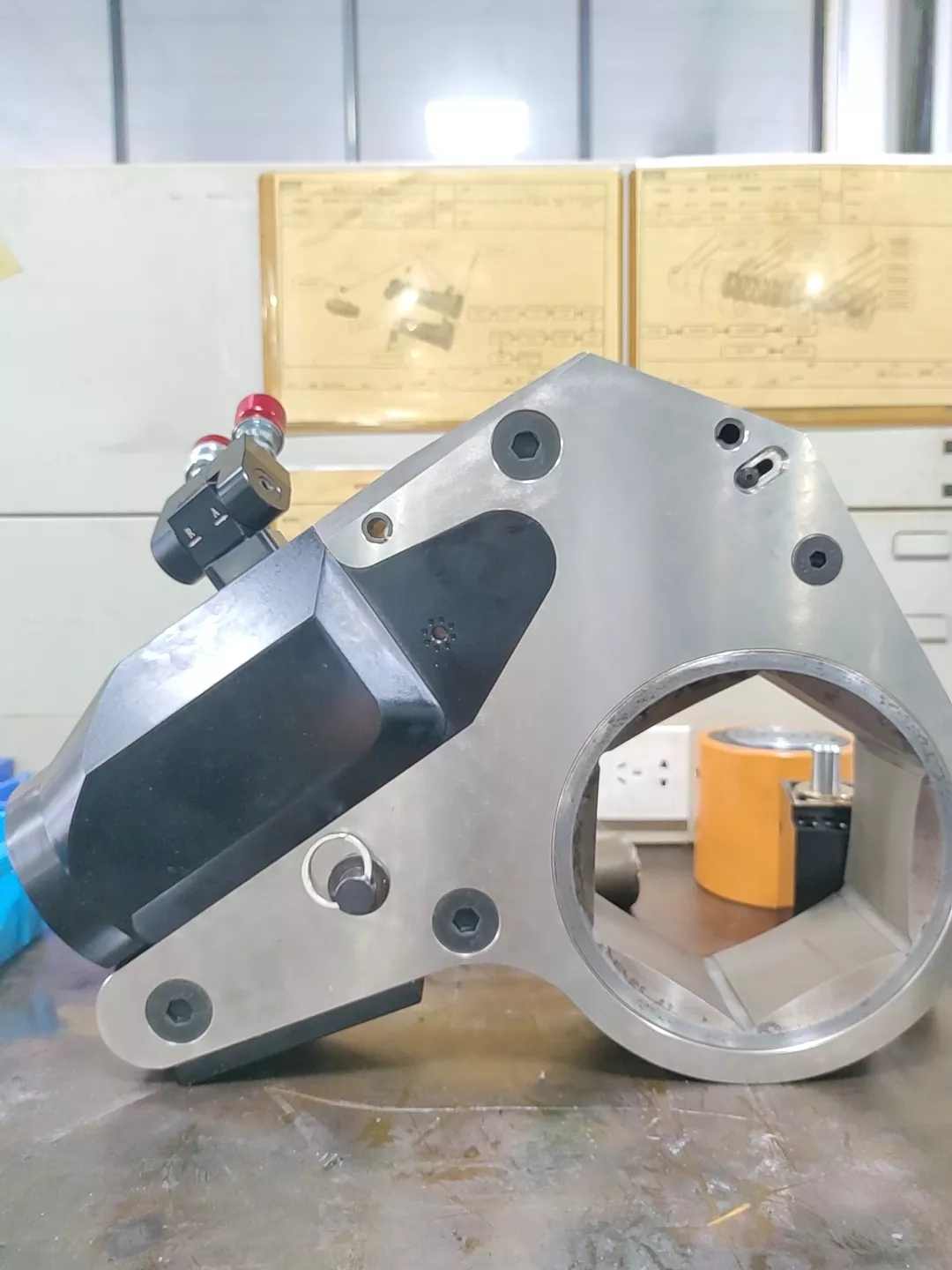

Using a Hydraulic torque wrench for flange bolting offers precision and safety in industrial environments.

However, proper technique is just as important as having the right tool. In this guide, we’ll walk through essential steps that ensure a successful flange bolting process and long-term sealing performance.

Why Proper Flange Bolting Matters

In pipelines, pressure vessels, and structural assemblies, flanges are critical connection points.

Improper bolting can lead to gasket failure, leaks, and even equipment damage.

That’s why controlled tightening with a hydraulic torque wrench is the industry standard for high-pressure applications.

Step-by-Step Guide to Flange Bolting

1. Inspect and Prepare the Work Area

Before tightening, inspect the flange faces, bolts, nuts, and gasket. Remove any dirt, corrosion, or foreign material. Confirm that all components meet the required standards.

Also check the hydraulic torque wrench, hoses, and pump for signs of wear or leakage. Equipment failure during operation can be dangerous and costly.

2. Set the Proper Torque Value

Each flange has a recommended torque value based on the material, bolt diameter, and gasket type. Refer to engineering specifications or manufacturer guidelines to set your hydraulic wrench’s pressure correctly.

Accurate torque settings ensure bolt tension is evenly distributed and avoids overstressing the bolts.

3. Apply the Correct Bolting Sequence

Using a star or crisscross pattern is essential when tightening flange bolts. This technique helps distribute pressure evenly across the flange and reduces the risk of pinching or damaging the gasket.

Typically, tightening is done in multiple passes — for example, 30%, 60%, and 100% of the target torque — to gradually seat the gasket.

4. Maintain Control Throughout the Operation

Operate the hydraulic torque wrench slowly and steadily. Do not exceed the tool’s rated pressure or torque capacity. Over-torquing may strip threads or deform the flange.

Ensure all bolts reach the final target torque in the correct sequence. Recheck the values if needed, especially in critical sealing applications.

Reliable Tools for Flange Bolting Success

We provide a full range of industrial hydraulic torque wrenches, including square drive and low-profile models.

Our tools are engineered for accuracy, durability, and safety in heavy-duty applications.

Contact us today for expert assistance in selecting the right torque tools for your flange bolting requirements.