Plunger Pump Maintenance Guide for Long-Term Performance and Safety

Plunger Pump Maintenance Guide for Long-Term Performance and Safety

Plunger pumps are widely used in various industrial fluid transfer applications due to their efficiency and high-pressure capabilities.

To ensure the longevity and operational reliability of these pumps, a strict maintenance schedule must be followed.

This article outlines the standard and secondary maintenance procedures for plunger pumps based on accumulated operating hours.

Regular Maintenance at 1000-1200 Hours

Once a plunger pump reaches 1000 to 1200 hours of operation, it is essential to perform regular maintenance, typically carried out by qualified water injection pump operators. The following steps ensure continued performance and prevent early wear:

Key Maintenance Tasks

① Clean the crankcase air filter thoroughly to avoid internal contamination.

② Tighten all fastening nuts to prevent mechanical loosening during operation.

③ Adjust the gland packing box to ensure proper seal integrity and prevent leakage.

④ Inspect the suction and discharge valves for potential leakage or malfunction.

⑤ Check all automatic control instruments and valves for performance, responsiveness, and flexibility.

⑥ Adjust the coupling belt for optimal tension and alignment.

Secondary Maintenance at 4000-4800 Hours

When a plunger pump reaches between 4000 and 4800 hours of use, a more comprehensive secondary maintenance process is required.

This includes all regular maintenance tasks, plus several additional actions to enhance reliability and safety.

Additional Maintenance Procedures

① Lubricate the motor bearings by adding appropriate grease to reduce friction and overheating.

② Check both the large and small pulleys for looseness, and ensure their end faces are on the same plane to avoid misalignment.

③ Calibrate the instruments in the automatic control box and test the vibration switch to verify that all safety devices are accurate, responsive, and reliable.

④ Examine the lubrication system. Ensure smooth oil flow and replace the crankcase oil every six months. Clean any sludge or debris in the oil reservoir.

Why Proper Plunger Pump Maintenance Matters

Regular and timely maintenance not only prevents unexpected breakdowns but also extends the pump's service life and ensures optimal performance.

Industrial operations that rely on high-pressure fluid transfer systems must prioritize preventive maintenance to reduce costly downtimes.

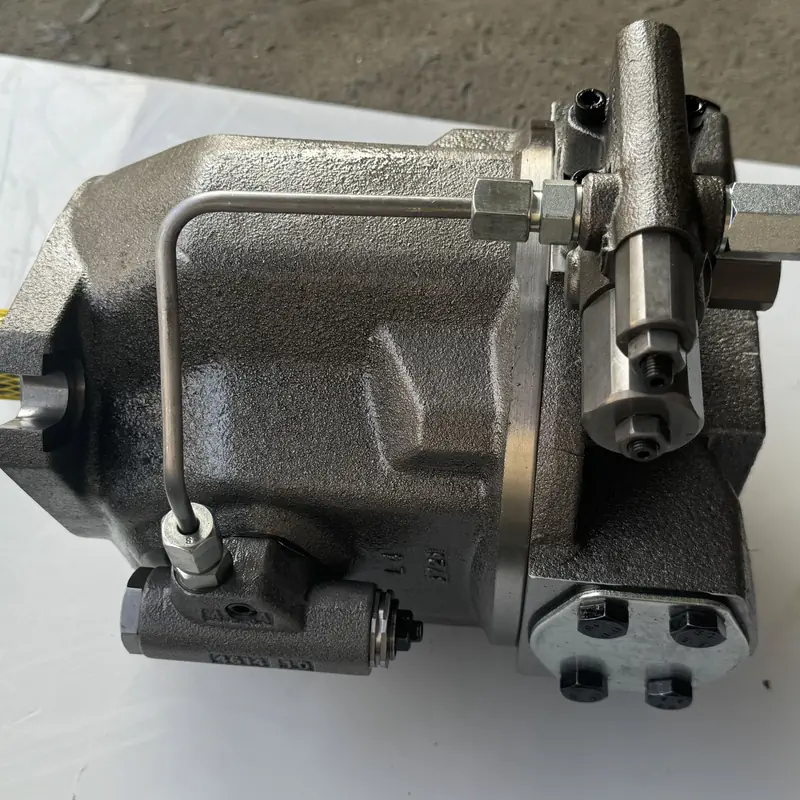

As a reliable supplier of industrial pumping equipment, our company provides high-quality plunger pumps and offers maintenance support to meet your operational needs. Contact us for bulk orders, OEM requirements, or technical consultation regarding pump reliability and upkeep.