Mastering the Inner Workings of a Hydraulic Power Unit

In hydraulic power packs, the term "hydraulic power" refers to the process by which a system of piping connected

by a pressurized fluid can generate, control, and transmit mechanical power from one point to another.

How hydraulic power units Work

hydraulic power units, or hydraulic power packs, are self-contained systems that convert mechanical energy into hydraulic energy.

They are used in various applications, including construction equipment, manufacturing machinery, and mobile hydraulics.

The basic components of a hydraulic power unit are a motor, a pump, a reservoir, and a control valve.

The motor drives the pump, which in turn pumps hydraulic fluid from the reservoir.

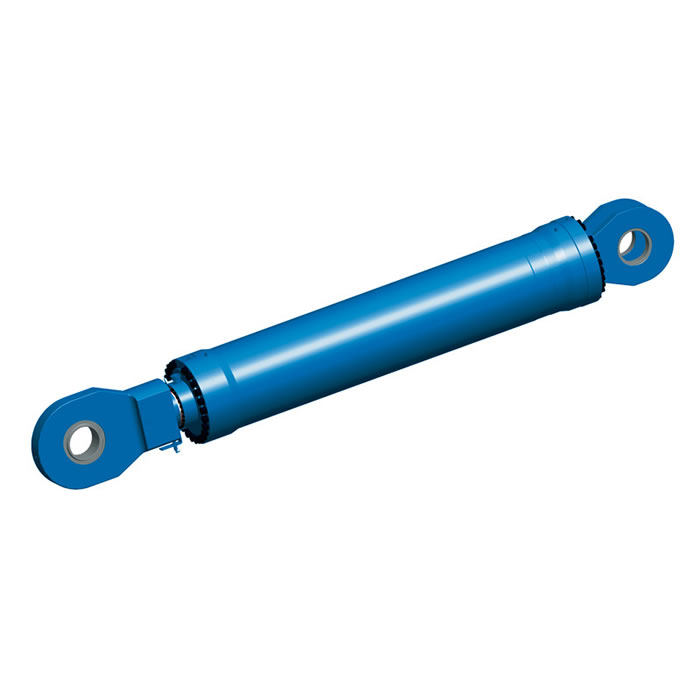

The control valve directs the fluid flow to the actuators, which are the devices that convert the hydraulic energy into mechanical energy.

Components of a Hydraulic Power Unit

A hydraulic power unit is a self-contained system that converts mechanical energy into hydraulic energy.

It is the heart of a Hydraulic System and provides the power to operate hydraulic actuators such as cylinders and motors.

Several key components make up a hydraulic power unit, each playing a vital role in its operation and performance.

Here's a breakdown of the essential parts:

1. Motor Pumps

Every power unit has at least one motor pump, which is responsible for converting mechanical energy from the motor into hydraulic energy.

Some units may have multiple pumps for increased flow or pressure.

Pumps can be of various types, such as gear pumps, vane pumps, or piston pumps,

each with its characteristics and suitability for different applications.

2. Filters

Hydraulic fluid cleanliness is crucial for system longevity and performance.

Filters remove contaminants like dirt, metal particles, and debris from the fluid.

Most power units have at least one filter, often located near the pump inlet.

Some filters are self-cleaning, automatically removing contaminants and extending their lifespan.

Regular filter maintenance is essential to prevent system blockage and component wear.

3. Power Unit Controllers

The power unit controller is the brain of the system.

It allows you to monitor and control various aspects of the unit, such as pressure, flow, and temperature.

Controllers can be simple manual units with basic switches and gauges or complex electronic systems with displays,

data logging capabilities, and even remote control functionalities.

4. Accumulators

Accumulators store hydraulic fluid under pressure and provide a surge of power when needed.

They can also help to dampen pressure fluctuations and reduce system shock.

Accumulators are often used in applications requiring rapid actuator movement or high peak loads.

5. Coolers and Heaters

Hydraulic fluid needs to be maintained within a specific temperature range for optimal performance.

Coolers, typically located near the filter or return line, prevent overheating by dissipating excess heat.

In cold environments, heaters can be used to maintain the fluid temperature within the operating range.

6. Tanks

The hydraulic power unit tank serves as a reservoir for the hydraulic fluid.

It also provides space for air separation and allows for the settling of contaminants.

Tanks can be of various sizes and designs, depending on the system's flow and capacity requirements.

Proper operation of a power unit is crucial for system functionality.

Malfunctions in any component can disrupt the entire system, leading to failure.

Regular maintenance is essential to prevent unnecessary wear and potential breakdowns.

Delaying maintenance can result in costly downtime, an undesirable situation for any business.

By understanding the components of a hydraulic power unit and their functions,

you can make informed decisions about selecting the right unit for your specific needs.

SAIVS is a trusted partner for hydraulic system solutions, offering maintenance and repair services for hydraulic power units from various manufacturers.

For more information on our power units or hydraulic system services, please get in touch with us.