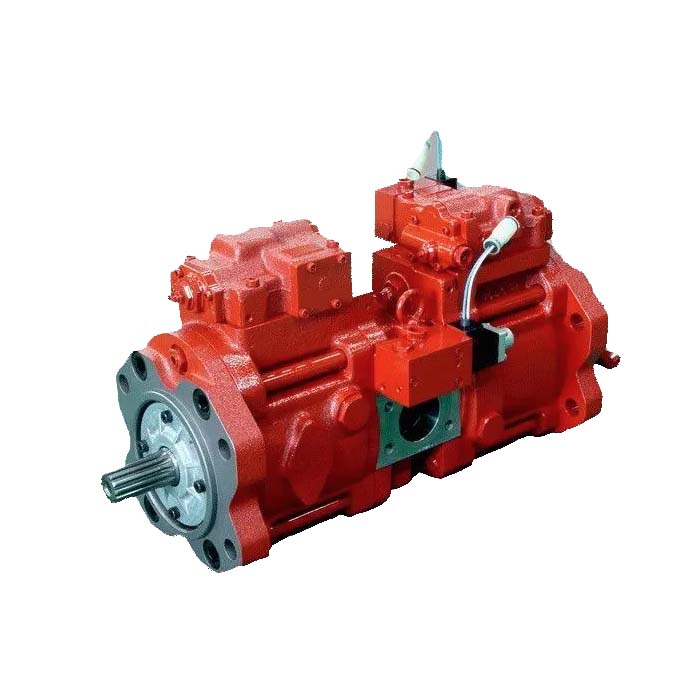

Kawasaki Hydraulic Pump Maintenance and Adjustment

Kawasaki hydraulic pumps are a type of hydraulic pump that is used in a variety of applications,

including construction equipment, agricultural machinery, and industrial machinery.

These pumps are known for their durability and efficiency, but they can still experience problems over time.

I. Kawasaki Hydraulic Pump Repair

The most common repairs that are performed on Kawasaki Hydraulic pumps are:

Seal replacement: Seals are used to prevent fluid leaks from the pump. When seals wear out,

they can cause leaks that can lead to damage to the pump and other components.

Bearing replacement: Bearings are used to support the rotating parts of the pump.

When bearings wear out, they can cause noise, vibration, and even failure of the pump.

Valve replacement: Valves are used to control the flow of fluid through the pump.

When valves become damaged, they can cause problems with the performance of the pump.

Corrosion: Corrosion can damage the internal components of the pump, including the housing, pistons, and cylinders.

Mechanical damage: Mechanical damage can occur if the pump is not properly maintained or if it is subjected to a sudden impact.

Follow these essential steps to keep your hydraulic pump in top condition:

Fluid Level Check:

Monitor the hydraulic fluid level regularly and ensure it is within the recommended range.

Low fluid levels can lead to pump inefficiency and potential damage.

Top up or replace the fluid as needed, following the manufacturer's specifications.

Filter Replacement:

Replace the hydraulic fluid filters at recommended intervals.

Clean filters help maintain the pump's efficiency by preventing contaminants from entering the system.

Follow the manufacturer's guidelines for filter replacement.

Seal Inspection:

Inspect all seals and gaskets for signs of wear or damage. Replace any

compromised seals to prevent fluid leakage and maintain the pump's efficiency.

Temperature Monitoring:

Keep an eye on the operating temperature of the hydraulic pump.

Excessive heat can lead to fluid degradation and pump malfunction.

Install temperature gauges and address any overheating issues promptly.

II. Kawasaki Hydraulic Pump Adjustment Methods

Flow adjustment:

The flow of fluid through the pump can be adjusted to change the performance of the pump.

For example, increasing the flow will increase the power of the pump, while decreasing the flow will reduce the power.

Pressure adjustment:

The pressure of the fluid that is output by the pump can be adjusted to change the performance of the pump.

For example, increasing the pressure will increase the force that is applied to the actuator,

while decreasing the pressure will reduce the force.

Variable Displacement Setting:

For variable displacement pumps, adjust the swash plate or other control mechanisms to vary the pump's displacement.

This adjustment is crucial for matching the pump output to the load requirements.

Alignment Check:

Ensure proper alignment of the hydraulic pump with the engine or motor.

Misalignment can lead to increased wear and reduced efficiency.

Adjust the coupling or mounting as needed for correct alignment.

To adjust the flow or pressure of a Kawasaki hydraulic pump, you will need to use the appropriate tools and procedures.

The specific procedures for adjusting the flow and pressure of a Kawasaki hydraulic pump will vary depending on the type of pump.

*Troubleshooting

Leaking hydraulic pump: Leaking is a common problem with hydraulic pumps. Leaks can be caused by worn seals, bearings, or valves.

Noisy hydraulic pump: Noise can be a sign of bearing wear, valve damage, or other problems within the pump.

Reduced hydraulic pump performance: Reduced performance can be caused by worn seals, bearings, or valves, or by misalignment of the pump.

We can provide models of Kawasaki hydraulic pumps, including K5V, K3V, K3VL, and K3VG.

Kawasaki Hydraulic pump K5V series

If you are looking for high-performance and reliable hydraulic pumps, Kawasaki is a worthwhile choice to consider.

Please visit our website for the latest quotation!