Hydraulic technology in the food and beverage industry

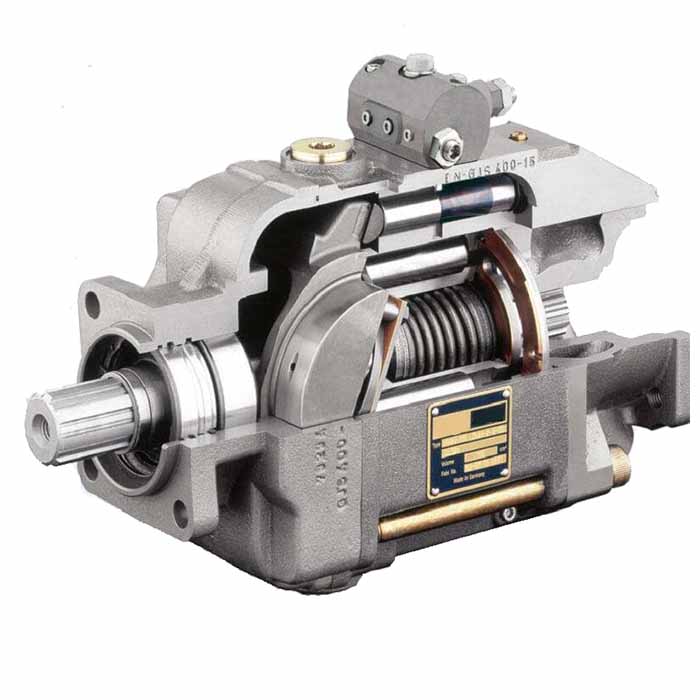

Hydraulics and pneumatics are critical components in the food and beverage industry,

providing the necessary power and precision for tasks ranging from conveyance to transportation.

Pneumatic cylinders are commonly used in conveyance systems due to their easy-to-clean design and compact size,

while hydraulics are often used for mixing and transportation of heavy products.

Both systems are able to withstand harsh work environments and generate high pressures and speeds.

In packaging, vacuum pressure provided by pneumatic systems is effective in lifting

and manipulating delicate or non-symmetric food items, while hydraulics are able to handle the weight of multiple products.

The cleanliness and sanitation requirements of the industry demand reliable equipment for cleaning,

which both hydraulic and pneumatic systems provide. However, there are also challenges associated

with the use of these systems in the food and beverage industry. Cleaning and sterilization of the systems,

as well as compatibility with food-grade lubricants and fluids, are critical considerations to prevent contamination.

The selection of materials such as stainless steel and high-performance seals can greatly aid in the cleaning process

and ensure adherence to sanitation standards.

In conclusion, both hydraulics and pneumatics are essential in the food and beverage industry,

with each system being appropriate for specific applications. The reliability and power of these systems,

coupled with their ability to withstand harsh environments,

are vital for the efficient processing, preparation, and transportation of food and beverage products.

Here’s just a sampling of where you can find hydraulics and pneumatics at work in the food and beverage industry:

Chopping, cutting, slicing, and dicing systems

Massive mixers and blenders

Blow-molding and manipulation of food-grade packaging

Forklifts used to transport raw ingredients and finished products

Sealing of bottles and cans