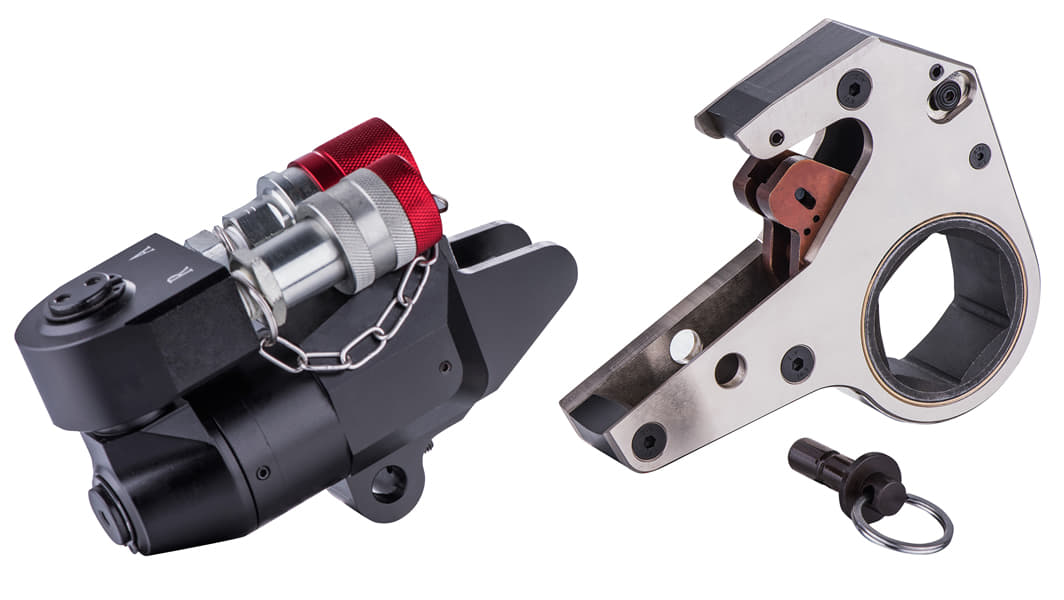

How to use the torque wrench correctly and the cause of the malfunction

I. How to use the torque wrench correctly

1. Set the required torque value and move the locking device to lock position;

2. Adjust the torque from the small value to the large value. If the torque exceeds the set value, adjust it back to the lower value.

3. Do not directly adjust from maximum to minimum;

4. Check whether the drive head is suitable or choose the proper adapter;

5. The center of the grip is the exerting position.

6. Before applying force, make sure that the wrench does combine with the object being applied.

7. Apply force smoothly and slowly. Stop applying force when the sound is heard and the spring is released.

8. Turn back the setting value to the minimum scale after use.

9.For large torque wrenches, the operator should pay attention to the center of gravity of the body.

II. Reasons for Torque Wrench Failure

1. The self-locking function can not be adjusted, which often happens because the range adjustment exceeds the maximum range; The locking key is too tight in the opposite direction.

2. No sound is heard when the excess is exceeded. The reason for this is the misalignment of the direction adjustment button.

3.The torque joint slips because the joint is not in place; Direction transfer knob not pulled in place.

4.Torque value cannot be adjusted, which is often the case when the locking key is self-locking.