How to Solve the Problem of Hydraulic Motor Heating

As a core component in the Hydraulic System, the heating problem of the Hydraulic Motor is one of the common failures. Heat not only affects the performance of the motor but also may lead to damage to other parts of the system. In this paper, we will analyze the causes of hydraulic motor heating and put forward the corresponding solutions.

Causes of hydraulic motor heating

The main reasons for hydraulic motor heating can be summarized as follows:

Fluid overheating:

System pressure is too high: too high a system pressure will increase the flow resistance of the liquid, resulting in a large amount of frictional heat.

Poor cooling effect: the cooling system is not designed properly or has poor heat dissipation, resulting in the fluid can not dissipate heat promptly.

Friction and wear:

Wear and tear of internal parts: Rotor, stator, and other parts inside the hydraulic motor cause friction at high speeds, leading to wear and tear and heat generation.

Deterioration of seals: Deterioration or damage of seals leads to increased internal leakage, increased friction, and heat generation.

Hydraulic oil quality:

Oil contamination: Hydraulic oil mixed with impurities, water and, other contaminants, will increase the viscosity of the liquid, increase the resistance to flow, heat generation.

Oil deterioration: Hydraulic oil oxidizes and deteriorates, losing lubricating properties, increasing parts wear, and generating heat.

Overloaded operation:

Excessive load: Hydraulic Motors are overloaded for long periods, resulting in excessive motor current and generating large amounts of heat.

Frequent starting and stopping: Frequent starting and stopping increases the shock load on the hydraulic motor and generates heat.

Solutions

For the above reasons, the following measures can be taken to solve the hydraulic motor heat problem:

Improve the cooling system:

Increase the cooling area: Increase the volume of the oil tank and increase the number of heat sinks.

Optimize cooling water flow: Ensure sufficient cooling water flow and good circulation.

Clean the radiator regularly: Remove dirt from the radiator to improve cooling efficiency.

Check the quality of the hydraulic fluid:

Replace the hydraulic fluid regularly: Replace the hydraulic fluid regularly according to the equipment instruction manual.

Select high-quality hydraulic oil: Select high-quality hydraulic oil that meets the requirements of the equipment.

Install an oil filter: Install an efficient oil filter to prevent impurities from entering the hydraulic system.

Adjust system pressure:

Reduce the system pressure: To meet the system requirements, reduce the system pressure appropriately.

Optimize the system design: Optimize the system design to reduce the pressure loss of hydraulic components.

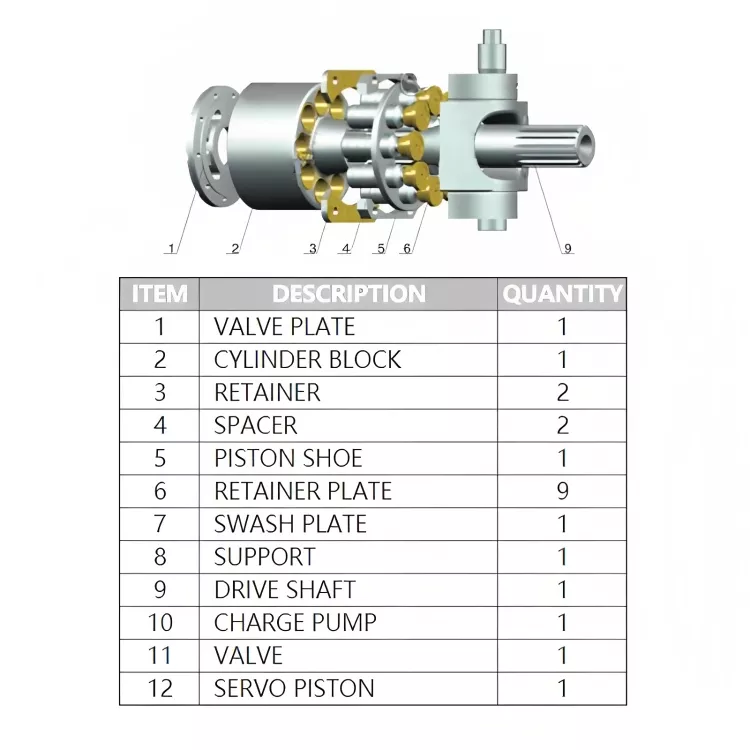

Check the internal parts of the hydraulic motor:

Dismantle and inspect: Periodically dismantle the hydraulic motor and inspect the internal parts for wear.

Replace worn parts: Replace worn parts promptly.

Reduce the load:

Distribute the load appropriately: Distribute the load appropriately according to the rated power of the hydraulic motor.

Optimize the working cycle: Optimize the working cycle to avoid prolonged overloading of the hydraulic motor.

Hydraulic motor heating is a complex systematic problem that requires comprehensive consideration of a variety of factors. Through the in-depth analysis of the causes of heat generation and the adoption of appropriate solutions, you can effectively reduce the heat generation of hydraulic motors and improve the reliability and service life of the system.