How to Increase Torque in a Hydraulic Motor

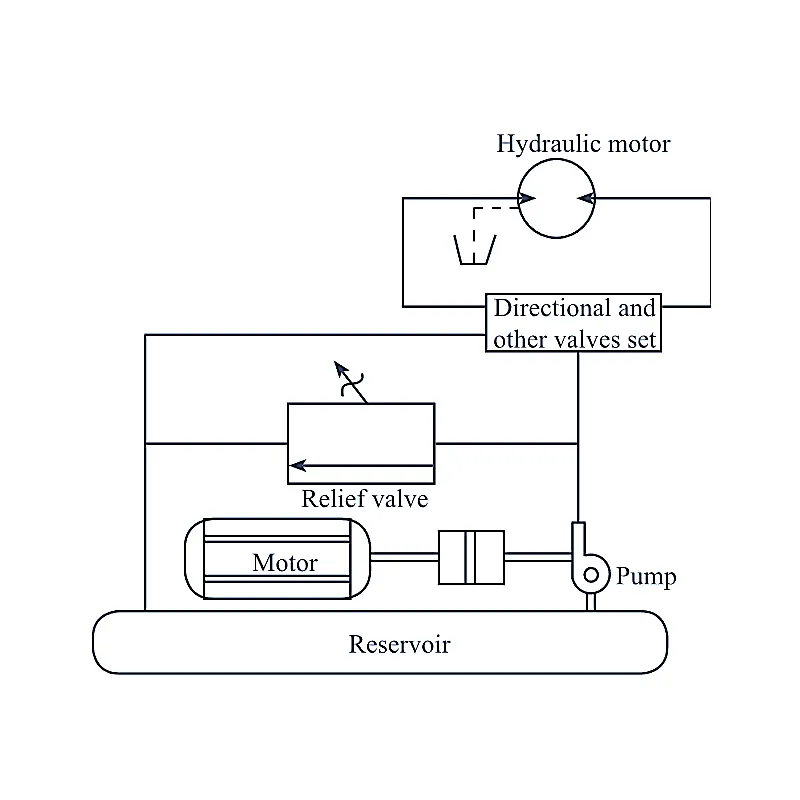

Hydraulic Motors are essential components in many Hydraulic Systems, converting hydraulic power into mechanical rotation. Torque, the turning force generated by the motor, is a crucial parameter for various applications. This article delves into the intricacies of torque in Hydraulic Motors, exploring its significance, potential losses, and effective methods to enhance it.

I. Understanding Torque in Hydraulic Motors

Torque is the rotational force that causes an object to rotate around an axis. In hydraulic motors, torque is generated by the pressure and flow of hydraulic fluid acting on internal vanes or pistons. The torque output of a hydraulic motor is directly proportional to the fluid pressure and displacement, and inversely proportional to the motor speed.

II. Significance of Torque in Hydraulic Motors

Torque plays a pivotal role in hydraulic motors, determining their ability to perform various tasks. Adequate torque is essential for overcoming loads, accelerating machinery, and maintaining consistent rotational speed. Insufficient torque can lead to motor stalling, reduced efficiency, and potential damage to the system.

III. Factors Causing Torque Loss in Hydraulic Motors

Several factors can contribute to torque losses in hydraulic motors, hindering their performance:

Internal Leakage: Internal leakage occurs when hydraulic fluid bypasses the intended passages, reducing the effective pressure and flow acting on the motor's vanes or pistons.

Frictional Losses: Friction between moving components within the motor, such as vanes, pistons, and seals, can dissipate energy and lead to torque losses.

External Inefficiencies: External factors like pressure drops in hoses, fittings, and valves can also contribute to torque losses by reducing the effective pressure reaching the motor.

IV. Strategies to Enhance Torque in Hydraulic Motors

To maximize the torque output of a hydraulic motor, consider the following strategies:

Increase Motor Speed: Raising the motor's rotational speed allows for a higher torque output at a given pressure. However, this may come at the expense of efficiency and potential wear on the motor.

Reduce Fluid Pressure: Lowering the operating pressure can minimize internal leakage and frictional losses, leading to improved torque efficiency. However, this approach may require a larger motor displacement to achieve the desired torque output.

Increase Fluid Volume: Utilizing a larger displacement motor provides a greater working volume for the hydraulic fluid, enabling it to generate higher torque at lower pressures. This method is particularly effective for low-speed, high-torque applications.

Conclusion

Torque is a critical aspect of hydraulic motor performance, influencing its ability to power various applications. By understanding the factors affecting torque generation and implementing appropriate strategies, engineers can optimize hydraulic motor performance and ensure efficient operation. Carefully selecting the motor size, operating pressure, and fluid flow rate can significantly enhance torque output and system efficiency.

In addition to the methods listed above, several other factors can affect the torque of a hydraulic motor, such as the type of motor, the viscosity of the hydraulic fluid, and the temperature of the fluid. It is important to consider all of these factors when selecting a hydraulic motor for a particular application.

Here are some additional tips for increasing the torque of a hydraulic motor:

Use a high-quality hydraulic fluid.

Keep the hydraulic fluid clean and free of contamination.

Regularly inspect and maintain the motor.

Use the correct size motor for the application.

Do not overload the motor.