How to Choose Between Torque Wrenches and Ratchet Wrenches

Introduction: Why Tool Selection Matters

When it comes to tightening fasteners, the difference between a reliable assembly and a catastrophic failure often comes down to the tool in your hand.

This article compares torque wrenches and ratchet wrenches from a technical, procurement, and production-quality perspective — with practical guidance on when to specify SAIVS torque tooling and how to integrate it into your workshop, plant, or field service operations.

What Is a Torque Wrench and Why It’s Essential

A torque wrench is a precision instrument designed to apply a specific rotational force (torque) to a fastener.

Where product safety, structural integrity, or mechanical performance depends on consistent clamp load, torque control prevents both under-tightening (which can cause joint separation) and over-tightening (which can cause bolt yield or component damage).

Types of Torque Wrenches

Click torque wrenches — the most common type — provide audible and tactile feedback when the preset torque is reached.

Dial and digital torque wrenches supply continuous readings; digital tools improve traceability and can often log or transmit torque data for quality records.

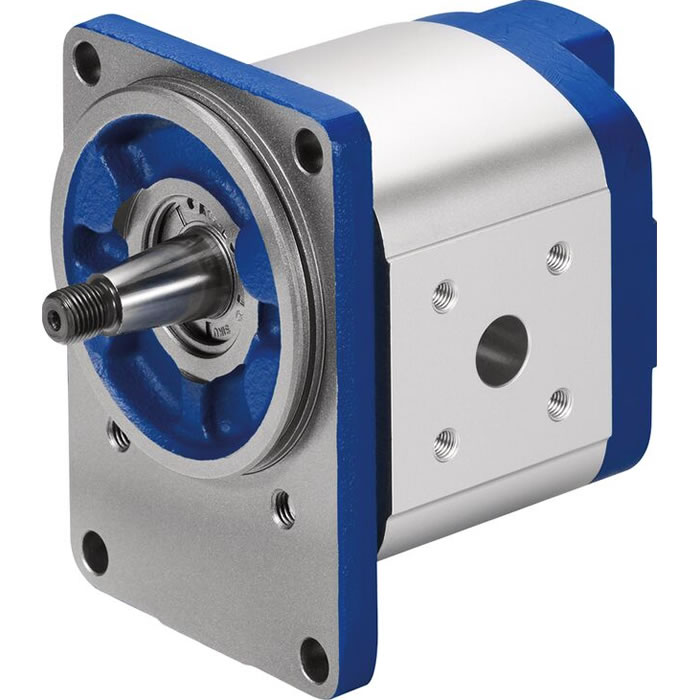

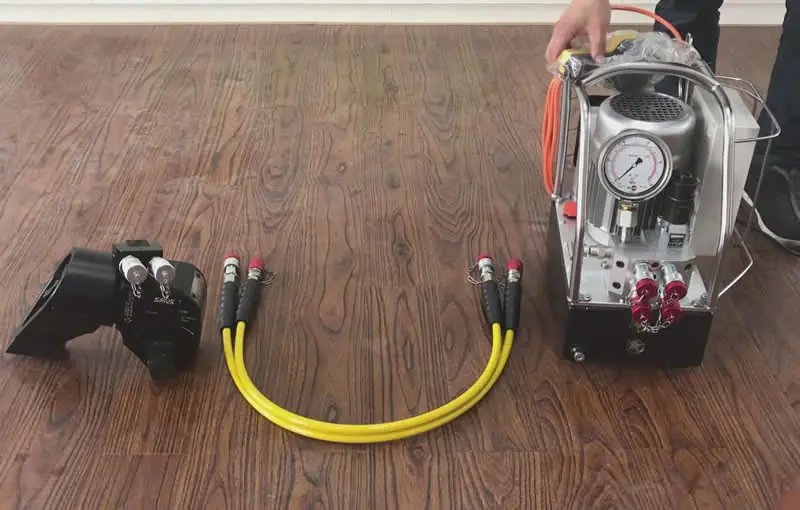

Hydraulic Torque Wrenches, especially in industrial applications, deliver high torque in a compact form factor and are often paired with electric pumps for multi-head operations. SAIVS hydraulic torque solutions include calibrated heads and modular sleeve sets to match fastener geometries precisely.

What Is a Ratchet Wrench and Where It Excels

A ratchet wrench is a general-purpose tool that uses a ratcheting mechanism to apply torque without repeatedly repositioning the handle.

Its strengths are speed, ease of use, and flexibility via interchangeable sockets. For routine maintenance, repairs, and applications where torque specification is not critical, the ratchet wrench is the pragmatic choice.

Configurations and Use Cases

Standard ratchet wrenches, flex-head designs, and combination wrenches (open end + ratcheting box end) provide solutions for confined spaces and rapid fastener cycles.

However, ratchets lack built-in torque control; user judgment or aftermarket torque-limiting adapters must be used when clamp load matters — a compromise that is no substitute for a calibrated torque wrench in critical assemblies.

Direct Comparison: Accuracy, Speed, and Cost

| Feature | Torque Wrench | Ratchet Wrench |

|---|---|---|

| Main Function | Apply precise torque | Speedy tightening/loosening |

| Torque Control | Yes — adjustable and calibrated | No — relies on user feel |

| Typical Accuracy | ±2–5% (varies by type) | Low |

| Best For | Safety-critical, spec-driven assemblies | General maintenance and rapid work |

| Cost | Higher initial investment | Lower cost, high ROI for general tasks |

Procurement and Total Cost of Ownership

Although torque wrenches require a higher upfront investment than ratchets, the cost of rework, warranty claims, and component failures associated with incorrect torque often makes high-quality torque tools the more economical choice over the product lifecycle.

SAIVS positions calibrated torque wrenches with clear traceability documentation and optional service contracts to reduce lifecycle risk and simplify supplier audits.

When to Specify a Torque Wrench — Practical Industry Examples

Use torque wrenches whenever the specification calls for a torque value or where clamp load affects function:

• Automotive: wheel lug nuts, cylinder head bolts, drivetrain fasteners.

• Aerospace: airframe and critical systems where torque traceability is mandatory.

• Manufacturing and heavy industry: machine tool assemblies, hydraulic fittings, and bolted flange connections.

• Construction: structural bolts that influence load paths and seismic performance.

When a Ratchet Wrench Is Appropriate

For routine maintenance, non-critical tasks, quick disassembly, and confined-space work where speed is paramount and torque specification is permissive, a ratchet is the efficient choice.

Nevertheless, when the task transitions from maintenance to retrofit, assembly, or final torqueing, switch to a calibrated torque wrench to validate clamp load.

Best Practices: Integrating SAIVS Torque Tools into Production

1. Define torque requirements in product specifications and work instructions.

2. Select torque tools that cover the required range with adequate resolution and calibration accuracy. SAIVS provides ranges from low inch-pounds to high foot-pounds and hydraulic solutions for extreme torque demands.

3. Train operators on correct sequencing (star/diagonal patterns), tool handling, and the difference between initial snugging and final torque application.

4. Establish calibration intervals, store calibration certificates, and integrate torque data capture where traceability is required.

5. Maintain spares for sleeves, sockets, and consumables to avoid downtime and ensure fit accuracy — a critical point for hydraulic wrench sleeves which directly influence torque transfer and fastener protection.

Why Choose SAIVS

SAIVS torque solutions combine field-proven ergonomics, durable materials, and documented calibration services. Our product lines are engineered for accurate, repeatable clamp loads and designed to minimize tool-to-fastener play. For procurement teams, SAIVS offers configurable kits, modular sleeves, and electric pump options that support dual-head installations to improve tightening balance and cycle times in production environments.

Conclusion and Call to Action

Selecting the correct wrench is not an either/or decision but a matter of matching tool capability to application risk. For critical torque control, choose calibrated torque wrenches; for speed and versatility, use ratchet wrenches — and for the best balance of production speed and accuracy, consider integrating SAIVS hydraulic torque systems with dual-head electric pumps and modular sleeve kits.

If you’re specifying tooling for new assembly lines or upgrading maintenance kits, contact SAIVS for tailored recommendations, calibration options, and procurement bundles that reduce total cost of ownership while improving product reliability.