How does a hydraulic torque wrench pump work?

Introduction

Hydraulic Torque Wrench pumps play a crucial role in various industries where precise

and controlled torque application is essential. In this article, we will explore the

inner workings of Hydraulic torque wrench pumps, their interaction with hydraulic

torque wrenches, and the advantages they offer in industrial applications.

What are hydraulic torque wrench Pumps?

Hydraulic torque wrench pumps are power sources that provide the necessary hydraulic

pressure to drive hydraulic torque wrenches. These pumps generate high-pressure hydraulic

fluid, typically oil, which is transmitted to the torque wrench for accurate and controlled torquing.

Hydraulic torque wrench pumps come in different types such as electric-powered pumps,

air-driven pumps, or manual hand-operated pumps. They are designed to be portable and

compatible with various sizes and types of hydraulic torque wrenches.

How Hydraulic Torque Wrenches Work with Torque Wrench Pumps?

The interaction between hydraulic torque wrenches and their accompanying pumps is vital

for achieving precise torquing results.

Here's how it works:

1. Power Generation: The pump generates high-pressure hydraulic fluid by converting an

energy source (electricity, compressed air, or manual force) into mechanical energy.

This pressurized fluid becomes the power source for driving the hydraulic torque wrench.

2. Fluid Transmission: The pressurized fluid is directed through hoses or tubes from the

pump to the hydraulic torque wrench. These hoses connect the

pump's outlet port to the inlet port of the tool.

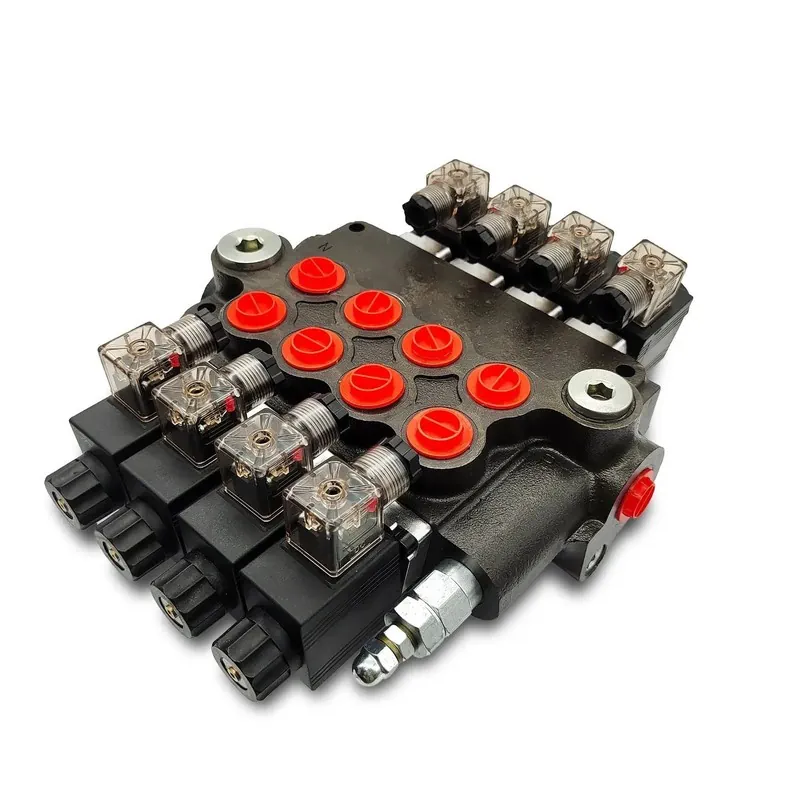

3. Control Mechanisms: Hydraulic torque wrench pumps feature control mechanisms that

allow users to adjust and maintain desired pressure levels during operation.

This control ensures accurate torquing without exceeding specified limits.

4. Torque Application: When pressure is applied through the fluid transmission system,

it activates internal mechanisms within the hydraulic torque

wrench itself (such as ratchets or gears). These mechanisms convert fluid pressure

into rotational force that drives fasteners with precision.

5. Monitoring and Feedback: Some advanced systems may include digital displays or remote

controls that enable users to monitor pressure levels during

operation for optimal control over torquing processes.

Advantages of Hydraulic Torque Wrench Pumps

Hydraulic torque wrench pumps offer several advantages in industrial applications:

1. Precision and Control: The use of hydraulics allows for precise application

of torques within specified limits, ensuring accuracy in fastening operations.

2.Efficiency:The high-pressure generated by these pumps enables rapid torquing

operations on large bolts or fasteners compared to manual methods.

3.Versatility:The compatibility between different types and sizes of

hydraulic tools allows flexibility across various applications.

4.Safety Features:Pumps often incorporate safety features such as overload protection

systems or pressure relief valves that prevent damage caused by excessive force.

5.Portability:The compact design of many pump models facilitates easy transportation between job sites.

6.Maintenance:Frequent maintenance checks help ensure optimal performance

by identifying any leaks or issues before they escalate into major problems.

Conclusion

In conclusion, a hydraulic torque wrench pump serves as a critical power source for

driving precision-driven hydraulically powered tools like a hydraulic torque wrench.

Their ability to generate high-pressure fluids ensures accurate torquing

while providing versatility across different applications.