Gear Pump Selection Principles and Basic Conditions

Selecting the appropriate gear pump involves a detailed analysis based on various factors including layout, terrain, water level conditions, and operational requirements. Here's a step-by-step guide on how to choose the right gear pump:

1. Determining Pump Type

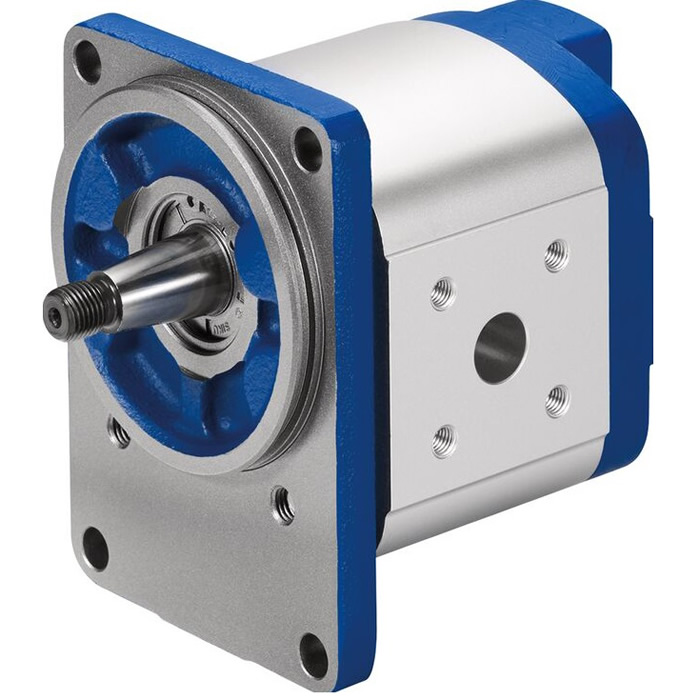

First, evaluate the arrangement of the installation, the terrain conditions, water level conditions, and operational requirements to decide whether to choose a horizontal, vertical, or other types (such as pipeline, submersible, vertical submerged, non-clogging, self-priming, gear type, etc.) gear pump.

2. Considering the Liquid Medium

Identify the type of liquid medium to be pumped. Determine whether you need a clear water gear pump, hot water gear pump, oil gear pump, chemical gear pump, corrosion-resistant gear pump, or an impurity gear pump. For areas prone to explosions, select a gear pump with an explosion-proof motor according to the explosion area classification.

3. Flow Rate and Head Requirements

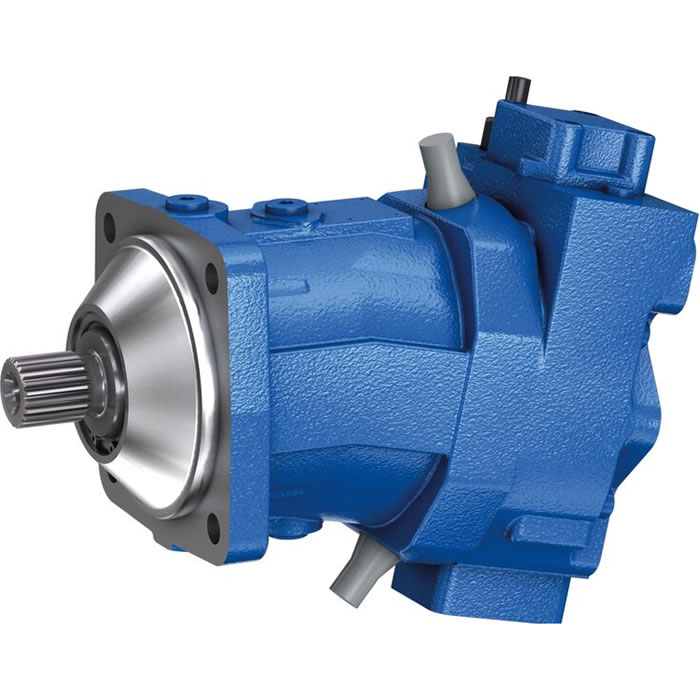

Flow Rate: Decide whether to use a single-suction or double-suction gear pump based on the flow rate requirements.

Head: Determine if a single-stage or multi-stage gear pump is needed based on the head requirements. Typically, single-stage gear pumps are preferred if they can meet the requirements, as multi-stage pumps generally have lower efficiency.

4. Determining Specific Pump Model

After selecting the type of gear pump, choose the specific model based on maximum flow rate (if unknown, usually 1.1 times the normal flow rate can be considered as the maximum flow rate). Add a margin of 5%-10% to the head requirement. Use the characteristic curves of the gear pump to identify the specific model:

Intersection Above Characteristic Curve: If the intersection of required flow rate and head is above the characteristic curve, the flow rate is sufficient but the head is inadequate. If the difference is within 5%, the pump can still be used; otherwise, choose a pump with a higher head.

Intersection Below Characteristic Curve: If the intersection is below the characteristic curve, the preliminary model can be determined based on the difference in head. For minor discrepancies, cutting the impeller diameter may be considered. If the difference is significant, select a pump with a smaller head.

5. Performance Verification

Verify the model's performance using product catalogs or sample data to ensure that the normal working point falls within the pump's optimal working range.

6. Adjustments for High Viscosity Liquids

For liquids with viscosities greater than 20mm²/s or densities over 1000kg/m³, convert the water test performance curves to account for the specific viscosity or density. Pay particular attention to suction performance and input power calculations.

7. Determining the Number of Pumps and Backup Rate

Generally, a single pump is preferred for normal operation due to higher efficiency compared to two smaller pumps in parallel. However, consider using multiple pumps in parallel in the following scenarios:

High Flow Rates: When a single pump cannot achieve the required flow rate.

High Backup Rate: For systems requiring a 50% backup rate, use two smaller pumps in operation with one in reserve.

24/7 Operation: For continuous operation, use three pumps—one operating, one on standby, and one under maintenance.

8. Manufacturer Consultation

Clients can submit their basic gear pump selection conditions to the pump manufacturer for model selection or recommendations. If the design institute has already determined the pump model during the equipment design phase, configure according to their specifications.

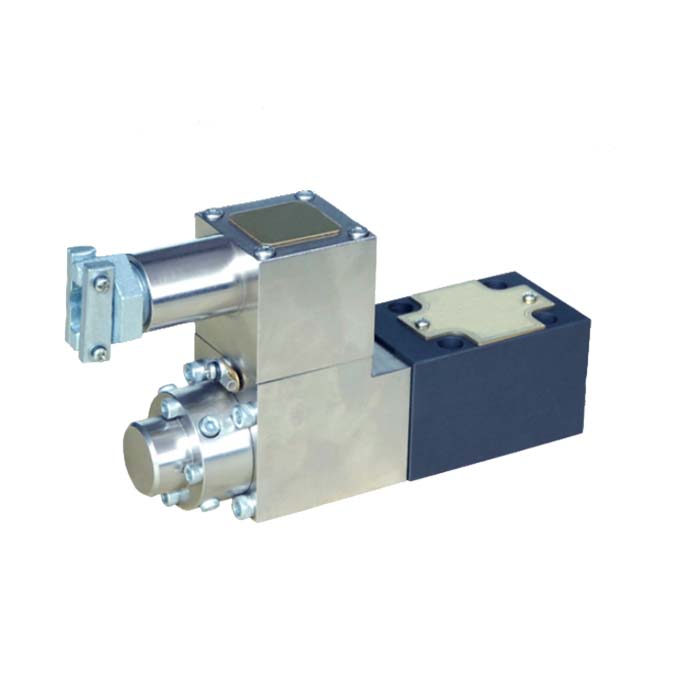

When selecting a gear pump, consider comprehensive factors such as working pressure, flow rate, speed, fixed or variable displacement, variable method, volumetric efficiency, overall efficiency, lifespan, compatibility with hydraulic oil, dimensions, weight, economy, and maintainability. These factors, often detailed in product catalogs or technical documents, should be thoroughly reviewed. For any unclear points, consult the relevant gear pump selection manuals from reputable manufacturers.

By following these principles and steps, you can ensure that the selected gear pump will meet the specific requirements of your application, providing reliable and efficient performance.