Best Torque Wrenches for Industrial Jobs

Types of Industrial Torque Wrenches

High-capacity torque wrenches can either be hydraulic,electric, battery-powered, or pneumatic.

Torque wrenches can be categorized further depending on their design and intended application.

Electric Torque Wrench

Battery-powered and corded electric torque wrenches

offer superior accuracy compared to their analog counterparts.

They can be pre-set to a desired torque level with a remarkable repeatability accuracy ranging

from ±3% to ±5%.When opting for a battery-powered torque wrench,

it is advisable to have extra batteries or a charger readily available.

This ensures uninterrupted operation and eliminates downtime due to battery depletion.

On the other hand, if you prefer corded electric torque wrenches,

it is crucial to ensure that there is a sufficient supply of clean

power that allows you to safely reach your work area.

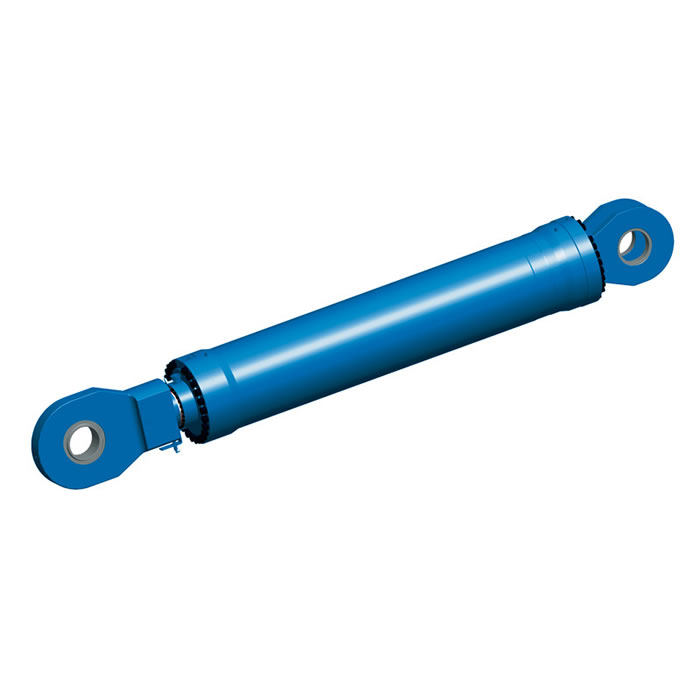

Hydraulic Torque Multiplier

For bolts that require a high amount of torque (or have been over-tightened),

torque multipliers can deliver additional torque without requiring extra force on the part of the operator.

Torque multipliers are essential for maintaining worker safety while tightening or loosening bolts by hand.

Multipliers can also increase torque at small intervals at a very slow pace,

reducing the risk of over-torquing or worker injury.

Like hydraulic tools, pneumatic torque wrenches

can deliver much higher torque than a manual or electric wrench,

but require additional equipment like an air hose and compressor.

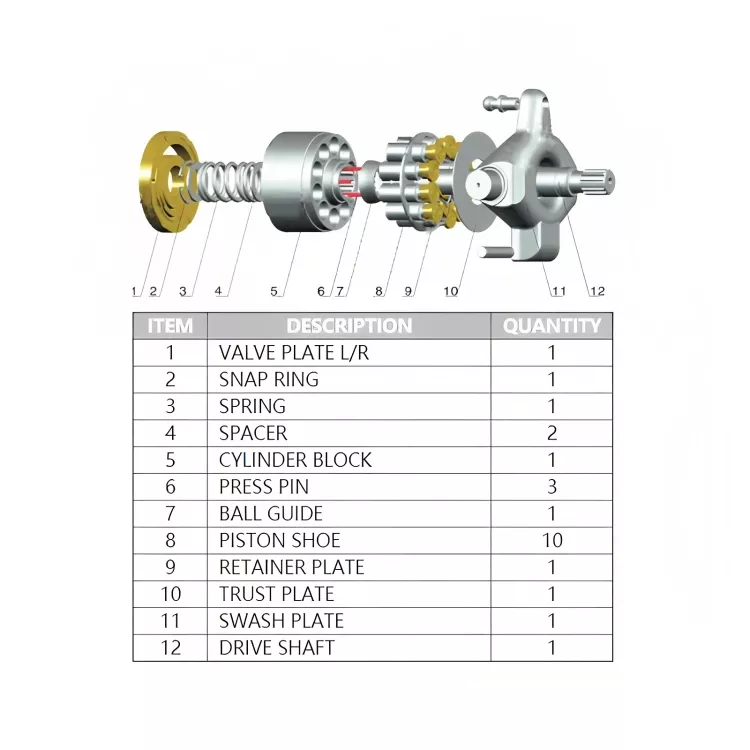

When it comes to larger jobs, Hydraulic torque wrenches

are able to deliver over 25,000 ft.-lbs. of torque.

They come in square-drive or low-profile designs called cassettes,

which consist of the cassette and drive unit.

Hydraulic wrenches themselves are quite light,

but are accompanied by heavy systems that can carry a high price tag.

Hydraulic Systems include pumps and a stiff hose that can be difficult to move.

hydraulic torque wrenches also carry safety concerns related

to pinch hazards and hydraulic fluid leaks, and should only be used by trained operators.

Torque Wrench Sources to Avoid

By selecting a supplier who can offer annual calibration services, certification documentation,

and necessary repairs for your torque tools,

you can maintain their optimal performance and prolong their lifespan while adhering to industry standards.

At SAIVS, we can meet all your needs, if you have any questions about torque wrenches,

please contact us, we are happy to talk with you.