A Guide to Maintaining SFSM Hydraulic Flange Expanders

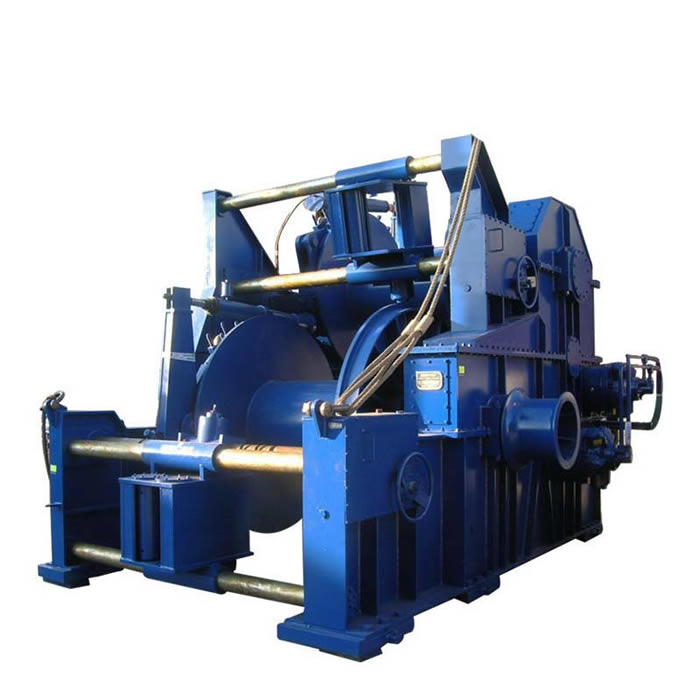

SFSM Series Hydraulic Flange Spreaders are a versatile tool that can be used in a variety of industrial applications.

They are designed to separate flanges, which are the joints that connect pipes.

These spreaders are available in a variety of sizes and capacities to meet the needs of different applications.

They can be used to separate flanges of different materials, including steel, cast iron, and aluminum.

Features:

-Integrated wedge concept: Friction-free, smooth, and parallel wedge movement eliminates flange damage and spreading arm failure

-Unique interlocking wedge design - no first step bending and risk of slipping out of joint

-Requires a very small access gap of only 6 mm

-Stepped spreader arm design - each step can spread under full load

-Few moving parts mean durability and low maintenance

1. Working Principle of a Flange Expander:

A flange expander is designed to enlarge the diameter of a flange, allowing for easy installation and alignment of pipes or other components.

The working principle of a flange expander involves the following steps:

Flange spreaders work by applying force to the flange bolts or studs. This force causes the flanges to separate.

Manual flange spreaders use a lever or crank to apply force to the flange bolts.

The lever or crank is connected to a threaded rod, which is then attached to the flange bolts.

Hydraulic Flange Spreaders use pressurized fluid to apply force to the flange bolts.

The fluid is pumped through a cylinder, which then applies force to the rod that is connected to the flange bolts.

2. How to Maintain a Flange Expander:

Proper maintenance of a flange expander is essential to ensure its optimal performance and longevity.

Follow these guidelines to effectively maintain a flange expander:

Regular Inspection:

Inspect the flange expander before and after each use. Check for any signs of wear, damage, or misalignment.

Pay close attention to the hydraulic or mechanical components, ensuring they are in good condition.

Cleaning:

After each use, clean the flange expander thoroughly to remove any dirt, debris, or residual contaminants.

Use a suitable cleaning agent and ensure that all parts, including the hydraulic or mechanical components, are thoroughly cleaned and dried.

Lubrication:

Apply a suitable lubricant to the moving parts of the flange expander to reduce friction and ensure smooth operation.

Refer to the manufacturer's guidelines for the recommended lubrication intervals and type of lubricant to use.

Calibration:

Periodically calibrate the flange expander to ensure its accuracy and precision.

Follow the manufacturer's instructions for calibration procedures and frequency.

This will help maintain consistent and reliable expansion results.

Storage:

When not in use, store the flange expander in a clean and dry environment.

Protect it from dust, moisture, and extreme temperatures.

Consider using protective covers or cases to prevent any potential damage during storage or transportation.

Professional Servicing:

If you notice any significant wear, damage, or malfunctioning of the flange expander,

consult a professional or the manufacturer for servicing or repairs.

Attempting to fix or modify the expander without proper knowledge

or expertise may lead to further damage or compromise its performance.

SAIVS

If you have any inquiries regarding the care and maintenance of your flange spreaders or any other equipment,

please don't hesitate to reach out to us. Alternatively, you can explore our products page for more information.