A Comprehensive Guide to Hydraulic Power Unit Maintenance

Introduction:

hydraulic power units play a crucial role in various industries, providing the necessary power to drive hydraulic machinery.

To ensure optimal performance and longevity of these units, a well-structured maintenance plan is essential.

Development of Hydraulic Power Unit Maintenance Plan:

A. Understanding the System:

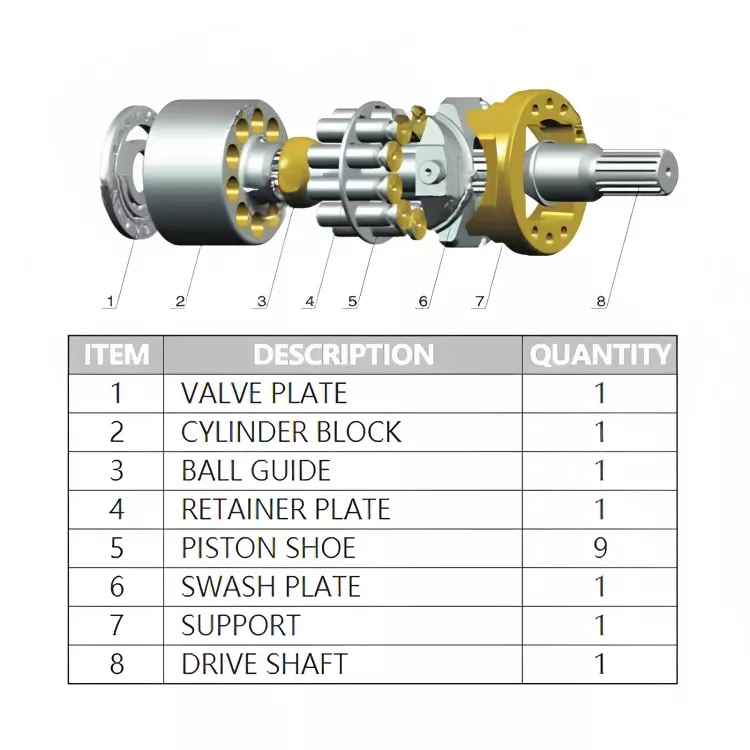

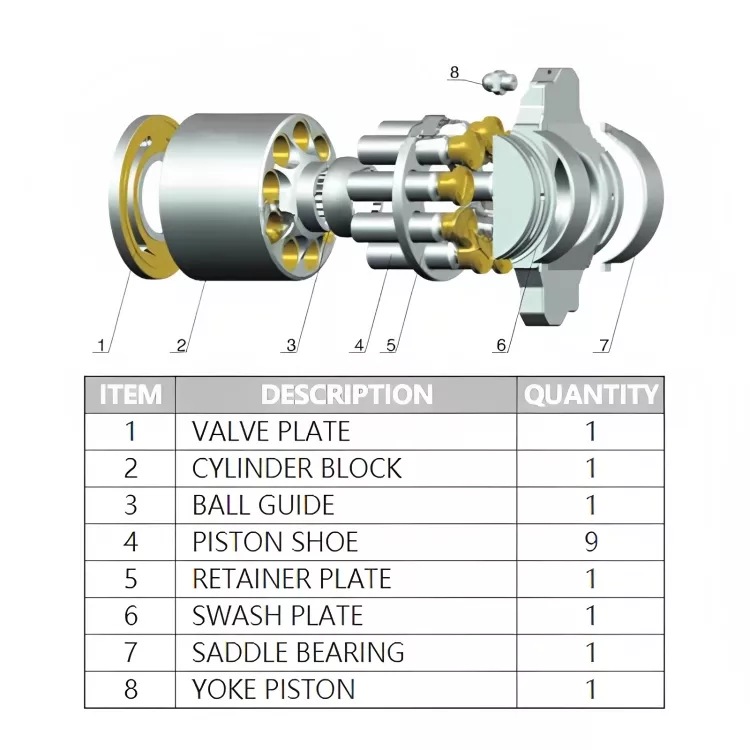

1. Identify key components and their functions.

2. Check the hydraulic power unit manufacturer's specifications and related guidelines.

B. Schedule Regular Inspections:

1. Establish a routine inspection schedule.

2. Prioritize critical components for thorough examination.

C. Documenting Findings:

1. Keep detailed records of inspections and maintenance activities.

2. Note any anomalies or potential issues for proactive resolution.

II. Preventive Maintenance for hydraulic power units:

Regular Filter Replacements:

Filters are vital components of hydraulic power units as they prevent contaminants from entering the system,

which can cause damage to the components and reduce overall efficiency.

It is recommended to establish a regular filter replacement schedule based on the manufacturer's guidelines.

This can help maintain the cleanliness of the hydraulic oil and ensure smooth operation.

Oil Level Checks:

Monitoring the oil level is crucial for the proper functioning of hydraulic power units. Insufficient oil can lead to increased friction,

overheating, and potential damage to the system.

Regularly check the oil level using the dipstick or sight glass provided by the manufacturer.

If the oil level is low, top it up with the recommended hydraulic oil.

Detection of Oil Leaks:

Oil leaks can significantly impact the performance and reliability of hydraulic power units.

Regularly inspect the unit for any signs of oil leakage, such as puddles or stains around the unit.

If a leak is detected, identify and rectify the source promptly. Leaks can occur due to damaged seals, loose connections,

or worn-out components. Addressing leaks promptly can help prevent further damage and ensure the longevity of the unit.

Monitoring Temperature and Pressure:

Monitoring the temperature and pressure of the Hydraulic System is crucial to prevent overheating and excessive pressure

that can lead to component failure. Install appropriate gauges or sensors to monitor these parameters.

Regularly check the readings and compare them with the recommended operating range provided by the manufacturer.

If any abnormalities are detected, investigate and address the underlying issues promptly.

Maintaining External Cleanliness:

While internal maintenance is crucial, the external cleanliness of the hydraulic power unit should not be overlooked.

Remove excess dirt, grime, and debris from the equipment regularly. This can be done using appropriate cleaning agents and tools.

A clean and well-maintained external surface helps prevent contamination and facilitates easy inspection of the unit.

SAIVS

Unmatched Expertise: Our team comprises of highly trained and experienced hydraulic technicians, equipped with the latest knowledge and tools to tackle any maintenance issue.

Comprehensive Services: We offer a full range of services, from routine inspections and fluid changes to in-depth system overhauls and component replacements.

Reliable and Responsive: We understand that downtime is costly. That's why we prioritize prompt service, flexible scheduling, and clear communication throughout the process.

Visit our website to learn more about our services.