9 Key Points for Daily Maintenance and Maintenance of Hydraulic System

Maintenance of the Hydraulic System is very important, and if the hydraulic system itself operates slowly, it has no significance or value for all filtration and analysis of the hydraulic fluid.

(1) Check fluid level.

(2) Check the breathing valve cover, the breathing valve filter and the injection screen - do not punch the screen to avoid over-filling.

(3) Check filter indicator and/or differential pressure gauge.

(4) Visually inspect all system hoses, pipes and pipe joints for leakage and wear.

(5) Check system temperature by built-in thermometer or hand-held infrared detector.

(6) Visually check whether there is aeration inside the oil tank: aeration refers to the condition that discrete bubbles enter the oil tank with the oil when the oil enters the hydraulic oil pump.

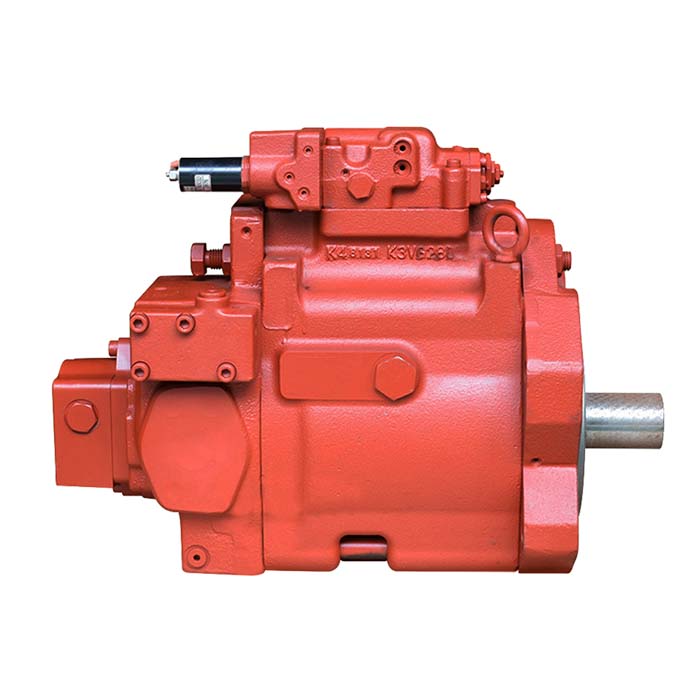

(7) Listen to the cavitation of the pump. Cavitation is slightly more complex than aeration, but they have little similarity. How to distinguish between aeration and cavitation? One method is to install a vacuum gauge on the suction side to ensure that the pressure is equal to or greater than the pump manufacturer's specified value. Foaming in tanks is usually a sign of aeration.

(8) Sampling to check the color, pollution and odor of the fluid. Note that visual inspection is limited to detecting signs of excessive contamination.

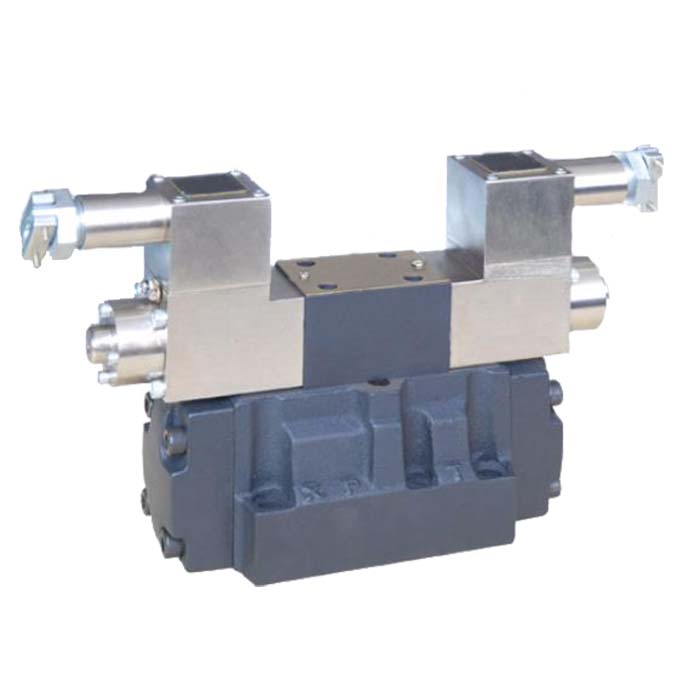

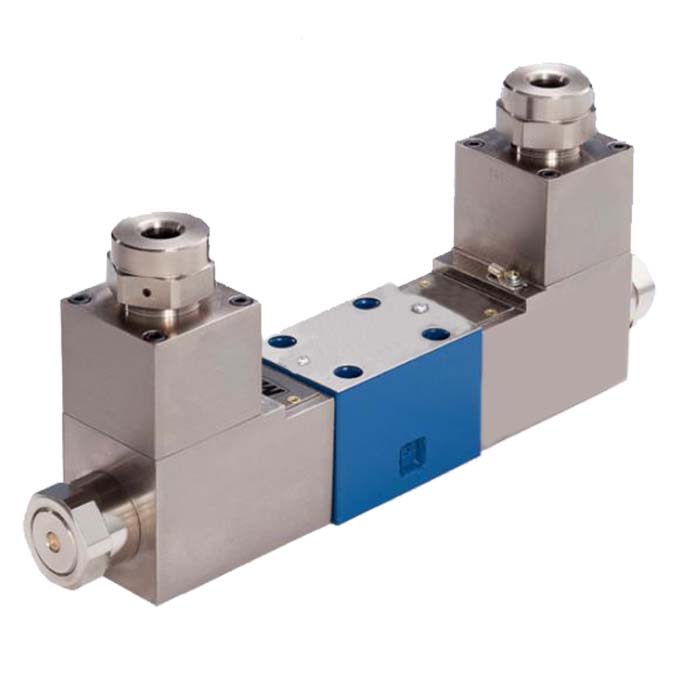

(9) Scan the electric servo valve with an infrared thermometer. Valves and solenoid valves at high temperatures (over 150°F) usually indicate that the valve is stuck.