The Future of Fluid Power: Are Hydraulic Vane Pumps Still Relevant

The Workhorse of Fluid Power

Hydraulic vane pumps are a cornerstone of fluid power technology, serving countless applications across various industries.

Invented in 1874, their simple yet effective design has withstood the test of time, making them a vital component for moving low-viscosity fluids

efficiently.

This article explores the inner workings of Vane Pumps, common causes of failure and preventive measures, and troubleshooting tips to keep your hydraulic

systems running smoothly.

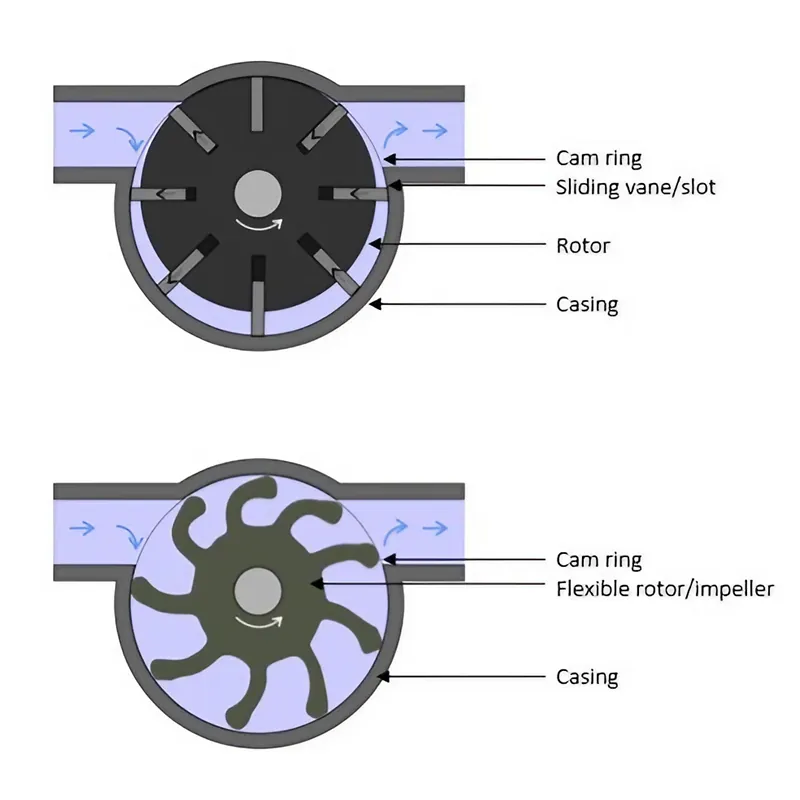

How Vane Pumps Work:hydraulic vane pump working principle

Vane pumps operate by trapping hydraulic fluid in a sealed chamber and progressively reducing the space as the rotor turns.

This pressurization process is achieved through the following key elements:

Sliding Vanes: These spring-loaded or pressure-activated vanes slide within the rotor slots, creating variable-sized chambers that trap fluid.

Inlet and Discharge Holes: Fluid enters the pump through the inlet and exits at high pressure through the discharge hole.

Off-center Drive Shaft: The positioning of the drive shaft relative to the chamber creates the pressure increase as the off-center rotor rotates,

forcing the vanes to compress the fluid and expel it through the discharge hole.

This simple design contributes to the ease of maintenance associated with vane pumps.

What Materials are Vanes Made Of

Vanes in sliding vane pumps are commonly made from materials capable of self-lubrication to ensure smooth sliding within rotor slots and against the

casing. Various materials are utilized based on specific requirements, such as carbon, PEEK (Polyether Ether Ketone) for chemical resistance,

glass-fiber reinforced PTFE, or bronze.

Common Causes of Failure and Preventive Measures

Dirty Fluid: The leading cause of vane pump failure. Contamination can accelerate wear and tear on components, leading to malfunctions.

Here's how to prevent it:

Filtration: Install and maintain proper filtration systems to ensure clean fluid.

Quality Control: Filter and verify the purity of new fluid before introducing it to the system.

Machine Cleanliness: Clean new equipment thoroughly before operation to avoid internal contamination.

Cavitation Damage: The implosion of air bubbles within the fluid can cause significant damage. Here's how to prevent it:

Air Intrusion: Maintain proper fluid levels, use an appropriate reservoir size, ensure good sealing throughout the system, and avoid suction line faults.

Excessive Force: Avoid high-pressure situations and restrict fluid flow restrictions. Operate within recommended RPM limits and maintain clean filters.

Signs of Hydraulic Vane Pump Failure

Noisy Operation: Unusual noises like knocking, banging, or loud whirring indicate problems.

Leaking: External leaks suggest seal failure or a bent rod.

Poor Performance: Reduced efficiency, pressure drops, and excessive heat are signs of potential trouble.

Early detection of these issues allows for repairs and prevents further damage.

Common Issues and Troubleshooting hydraulic vane pumps Tips

Early detection of problems is key to preventing costly repairs and system downtime. Here are some common signs to watch out for:

High Fluid Temperature: This can be a symptom of various issues and requires investigation.

Unusual Noise: Familiarize yourself with the normal operating sound of your pump.

Slow Performance: A sluggish pump could be caused by low fluid levels, stuck components, or using low-viscosity oil.

While these signs indicate potential problems, further investigation is needed for diagnosis.

Basic troubleshooting steps include visual inspection, fluid analysis, and awareness of cavitation.

Repair Service

Complex repairs or situations requiring specialized tools and expertise are best left to professionals.

If the problem seems beyond basic troubleshooting or requires disassembly of the pump, seek professional repair services.

By understanding common vane pump issues and knowing your limitations, you can take proactive steps to maintain your Hydraulic System and ensure

smooth operation. Remember, early detection and professional intervention when necessary can save your company time, and money, and prevent costly system failures.